-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Bright Anneal 304 Stainless Steel Strip 1/4H 1/2H 3/4H FH Stainless Steel Roll 1.4301

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 304 316L 321 310S |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1 - 10.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 2 Ton |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 1.4301 Stainless Steel Strip,Bright Anneal Stainless Steel Strip,1/2H Stainless Steel Strip |

||

Bright Anneal 304 Stainless Steel Strip 1/4H 1/2H 3/4H FH Stainless Steel Roll 1.4301

| Product Name | Stainless Steel Strip Roll |

| Thinckness |

Cold rolled:0.3mm-3mm Hot rolled: 3.0mm-10mm |

| Standard Size | Cold rolled : Width 5 - 1219mm |

| Hot Rolled : width 10 - 1500mm | |

| Service | Cutting (laser cutting, plasma cutting, cutting machine), Bending |

| Surface Service | Raw finishing (2B NO.1) Finishing(HL 8K Checkered.etc) |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

| Mainly Grade |

200 series: 201, 202 300 series: 301 304 309S 310S 316L 316Ti 317L 321 347 400 series: 409, 409L, 410, 420, 430, 431, 439,441 , 443 , 444 |

| Brand | TISCO BAOSTEEL ZPSS LISCO JISCO |

| Application range | Decoration, Industry ,Kitchenwave ,Building, Elevator |

304 Stainless Steel Strip Features

- Weldability: 304 stainless steel strip has good weldability. These strips products can be used for vessel parts, stainless steel welding pipes, stainless steel flexible hose and corrugated pipe, etc.

- Heat Resistance: Heat resistance means that 304 stainless steel strip can still maintain its excellent physical and mechanical properties at high temperatures conditions.

- Corrosion Resistance: When the amount of chromium atoms in the steel is not less than 12.5%, the electrode potential of the steel can be abruptly changed from a negative potential to a positive electrode potential. Prevent electrochemical corrosion.

Prime Quality, Precision Feature

When it comes to 304 grade stainless steel strips manufacturing, we get that you need a long term partner, not just a supplier. Whether you need the small samples or the metal strips solution from start to end, our promise is providing you with the highest quality stainless steel strips, in the shortest delivery time, and at the most competitive price with the highest quality.

As the precision stainless steel strips manufacturing expert, we do the tight tolerance, every work that it is challenging. You just provide us an coming idea, we help turn it into actual product for you!

304 Stainless Steel Strip Applications

304 stainless steel strip is the most widely used chromium-nickel stainless steel strip.

It has good corrosion resistance, heat resistance, low temperature strength and mechanical properties.

This strip has good hot workability such as stamping and bending without heat treatment. It is resistant to corrosion in the atmosphere.

It is suitable for food processing line, storage and transportation, plate heat exchangers, bellows, household products, auto parts, medical appliances, building materials, chemicals industry, food industry, agriculture, ship parts, etc.

304 stainless steel is a nationally recognized food grade stainless steel material.

304 Stainless Steel Strip Chemical Composition

The chemical components of grade 304 stainless steel strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| 304 | ASTM A240 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 18.00-20.00 | 8.00-11.00 | – |

304 Stainless Steel Strip Mechanical Property

Below The Table Is For Your Reference:

| Grade | EN Grade | Yield Strength Rp0.2 (N/mm²) |

Tensile Strength Rm (N/mm²) |

Hardness | Vickers Hardness (HV) |

Elongation A80 % Min. |

| 304 | 1.4301 | ≥205 | ≥520 | ANN | Max200 | ≥40 |

| ≥450 | ≥700 | 1/4 Hard | 220-250 | ≥20 | ||

| ≥700 | ≥850 | 1/2 Hard | 250-310 | ≥8 | ||

| ≥880 | ≥1000 | 3/4 Hard | 310-370 | ≥4 | ||

| ≥1020 | ≥1150 | Full Hard | ≥370 | ≥1 |

304 Stainless Steel Strip Production Tolerance

Below The Table Is For Your Reference:

Thickness Tolerance:

| Thickness(mm) | Width<125mm | 125mm≤Width<250mm | 250mm≤Width<600mm |

|---|---|---|---|

| ≥0.03-0.10 | ±0.06T | ±0.10T | ±0.10T |

| ≥0.10-0.15 | ±0.01 | ±0.015 | ±0.020 |

| ≥0.15-0.20 | ±0.015 | ±0.020 | ±0.025 |

| ≥0.20-0.25 | ±0.015 | ±0.020 | ±0.025 |

| ≥0.25-0.30 | ±0.018 |

±0.025 | ±0.030 |

| ≥0.30-0.40 | ±0.020 | ±0.025 | ±0.030 |

| ≥0.40-0.50 | ±0.025 | ±0.030 | ±0.040 |

| ≥0.50-0.60 | ±0.030 | ±0.030 | ±0.040 |

| ≥0.60-0.80 | ±0.030 | ±0.040 | ±0.040 |

| ≥0.80-1.00 | ±0.030 | ±0.040 |

±0.050 |

304 Stainless Steel Strip Hardness

The typical Vickers hardness for the strip material must determinate after annealing process (Hardness Vickers Typical Range: 160HV-600HV).

But the soft materials of 304 stainless steel strip Vickers hardness is from 160HV to 190HV.

What are The Advantages of Using 304 Stainless Steel Strips

304 is one of the most popular stainless steel materials, and it has good corrosion resistance because it has 18% chromium and 8% nickel content.

When selecting stainless steel materials for various industries, 304 stainless steel strips are often chosen because of their many advantages.

The following are the advantages of 304 stainless steel strips:

- The main component of the stainless steel band is 304, which can be used as a decorative tube, industrial tube, and some shallow stretched products. Because it has better processing properties than 201 and 304L, it can be more widely used in production;

- The 304 stainless steel strip has high plasticity, toughness and cold deformation ability, and is not easy to form a hardening tendency during work;

- The intergranular corrosion resistance of the 304 stainless steel strip is good after welding or after the stress relief treatment;

- The heat treatment of 304 stainless steel strip can get good mechanical properties such as high strength and toughness;

- Different finish treatments can be given to the surface of 304 stainless steel strip to obtain excellent surface conditions such as bright surface or mirror surface;

- Excellent corrosion resistance in different environments such as atmospheric corrosion resistance, seawater corrosion resistance and high temperature oxidation resistance.

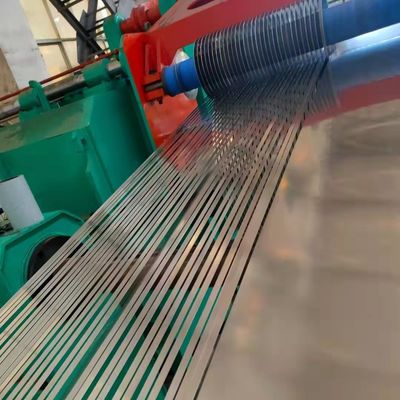

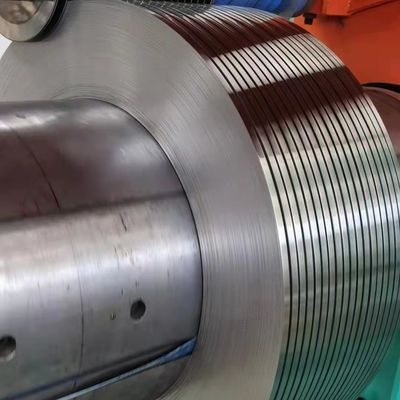

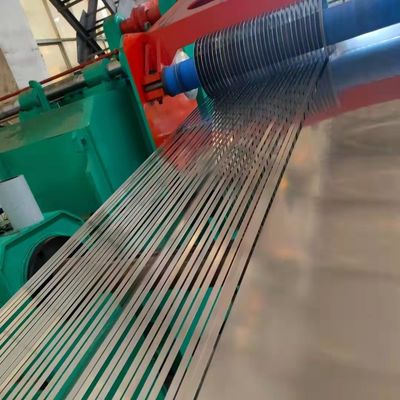

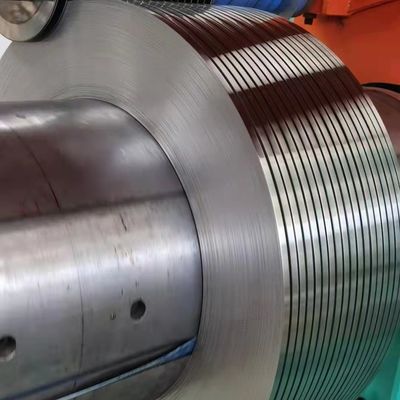

How 304 Stainless Steel Strips are Made

For 304 stainless steel strip production process, here you will be able to get a clear understanding of how to manufacture it with precision excellence technology:

- Technical Analysis

- Raw Material Preparation

- Rolling And Bright Annealing Process

- Degrease Cleaning Process

- Tension Straightening Process

- Slitting Process

- Inspection Process

- Packaging Process

![]()

![]()

![]()

![]()