-

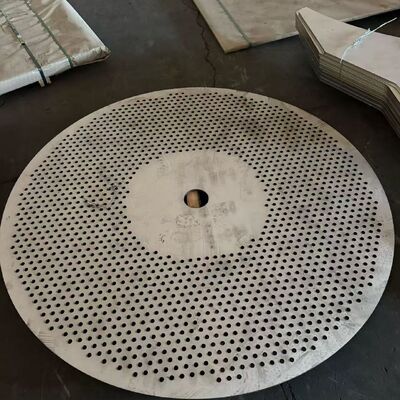

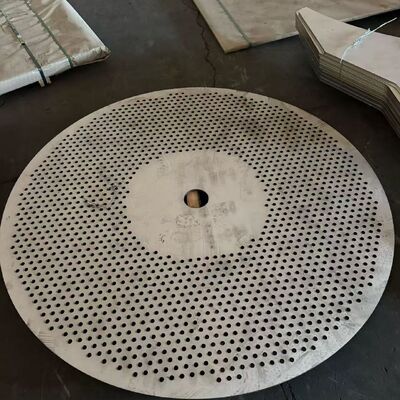

Прокладка нержавеющей стали

-

Лист нержавеющей стали

-

Плита нержавеющей стали

-

труба нержавеющей стали

-

Адвокатура нержавеющей стали

-

Гальванизированная стальная катушка

-

Стальная пластина

-

стальной круглый бар

-

сплав никеля

-

Безшовная стальная труба

-

Луч нержавеющей стали

-

Лист медной плиты

-

Медная круглая Адвокатура

-

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

EN 1.4462 & 1.4410 Duplex Stainless Steel Plate Laser Cutting Thickness 2.0 - 80.0mm With Smooth Edge

| Место происхождения | Китай |

|---|---|

| Фирменное наименование | DELTA |

| Сертификация | ISO |

| Номер модели | 2205 2507 |

| Количество мин заказа | 500 кг |

| Цена | 3200 - 3600 USD/Ton |

| Упаковывая детали | деревянные поддоны + водонепроницаемая бумага |

| Время доставки | 5-12 дней в зависимости от количества |

| Условия оплаты | Л/К, Т/Т, Вестерн Юнион |

| Поставка способности | 5 тонн в неделю |

Свяжитесь я бесплатно образцы и талоны.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Если вы имеете любую заботу, то мы предусматриваем 24-часовую интерактивную справку.

x| Продукты | пластина из нержавеющей стали | Оценка | 2205 2507 |

|---|---|---|---|

| Стандартный размер | 1500*6000mm | Толщина | 2,0–40,0 мм |

| Бренд | ТИСКО БАОСТИЛ ПОСКО ЛИСКО | Загрузочный порт | Шанхайский порт |

| минимальный заказ | 500 кг | Упаковка | деревянные поддоны + водонепроницаемая бумага |

| Выделить | Duplex stainless steel plate laser cutting,EN 1.4462 stainless steel plate,1.4410 duplex steel smooth edge |

||

EN 1.4462 & 1.4410 Duplex Stainless Steel Plate Laser Cutting Thickness 2.0 - 80.0mm With Smooth Edge

Products Specification

| Products | Duplex Stainless Steel Plate |

| Thickness | 1.0- 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

High-Performance Duplex Plates, Expertly Cut for Demanding Applications

Material Overview: EN 1.4462 vs. EN 1.4410

| Property | EN 1.4462 (Duplex 2205) | EN 1.4410 (Super Duplex 2507) |

|---|---|---|

| UNS Equivalent | S32205 / S31803 | S32750 |

| Type | Standard Duplex | Super Duplex |

| Microstructure | ~50% Austenite + 50% Ferrite | Balanced dual-phase (optimized for strength & corrosion) |

| PREN (Pitting Resistance)* | 34–38 | 40–45 |

| Yield Strength (Rp0.2) | ≥450 MPa | ≥550 MPa |

| Tensile Strength (Rm) | 620–750 MPa | 750–950 MPa |

| Max Service Temp | ~300°C | ~280°C |

| Key Alloying Elements | Cr 22%, Ni 5.5%, Mo 3.2%, N 0.17% | Cr 25%, Ni 7%, Mo 4%, N 0.28% |

| Typical Applications | Chemical tanks, heat exchangers, pipelines | Subsea manifolds, seawater systems, FGD scrubbers |

*PREN = %Cr + 3.3×%Mo + 16×%N — higher = better pitting resistance.

Laser Cutting Capabilities: 2.0–80.0 mm with Smooth Edges

| Thickness Range | Cutting Technology | Edge Quality | Notes |

|---|---|---|---|

| 2.0 – 25.0 mm | High-power fiber laser | ISO 9013 Class 2 | Ultra-smooth, vertical kerf; minimal dross |

| 25.1 – 50.0 mm | High-precision CO₂ laser | ISO 9013 Class 2–3 | Clean cut with slight taper (<2°); nitrogen assist |

| 50.1 – 80.0 mm | Advanced oxygen-assisted CO₂ laser + post-processing | ISO 9013 Class 3 | Smooth finish achieved via optimized parameters and light grinding if required |

✅ Heat input is tightly controlled to avoid sigma/chi phase formation in the HAZ

✅ Edges are smooth enough for direct welding or assembly in most cases

Technical Specifications

| Feature | Details |

|---|---|

| Material Grades | EN 1.4462 (X2CrNiMoN22-5-3), EN 1.4410 (X2CrNiMoN25-7-4) |

| Thickness Range | 2.0 mm to 80.0 mm |

| Standard Plate Sizes | 2000×6000 mm, 2500×6000 mm, 3000×12000 mm (custom blanks available) |

| Surface Finish | Hot-rolled (standard), pickled & passivated (optional) |

| Dimensional Tolerance | ±0.1 mm (≤10 mm), ±0.2 mm (10–30 mm), ±0.5 mm (>30 mm) |

| Edge Roughness (Ra) | ≤12.5 µm (typically 6.3–10 µm for <25 mm) |

| Certifications | EN 10204 3.1/3.2, ASTM A240, NORSOK M-650 (1.4410), PMI traceable |

| File Formats Accepted | DXF, DWG, STEP, IGES, PDF (with dimensions) |

Why Smooth Edges Matter in Duplex Steels

- Act as initiation sites for pitting or crevice corrosion

- Require time-consuming grinding before welding

- Compromise fatigue performance in dynamic loads

- Preventing scale formation through inert gas shielding

- Minimizing recast layer and micro-cracks

- Maintaining the alloy’s natural passive layer integrity

Applications by Industry

| Industry | Typical Components (Laser-Cut from 1.4462 / 1.4410) |

|---|---|

| Oil & Gas | Christmas trees, manifolds, choke valves, flowlines |

| Offshore & Marine | Riser clamps, seawater piping, ballast system parts |

| Chemical Processing | Reactor internals, distillation trays, acid storage vessels |

| Desalination | High-pressure RO housings, brine heater tubesheets |

| Power & Energy | Flue gas desulfurization (FGD) ducts, heat exchanger plates |

| Pulp & Paper | Bleach plant towers, digester components |

Quality Assurance Process

- Material Verification: All plates sourced from certified mills with full MTRs

- PMI Testing: Optional XRF/OES verification before and after cutting

- Process Control: Laser parameters logged per job (power, speed, gas pressure)

- Inspection: Visual + dimensional checks per ISO 9013; UT available for >40 mm

- Finishing: Optional pickling/passivation or light grinding for ultra-smooth edges

Ordering Information

- Minimum Order: 1 piece

- Lead Time: 5–15 working days (depending on thickness and complexity)

- Secondary Services: Beveling, marking (laser/engraving), protective film, export packaging

- Global Shipping: FOB, CIF, or DDP options available