모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

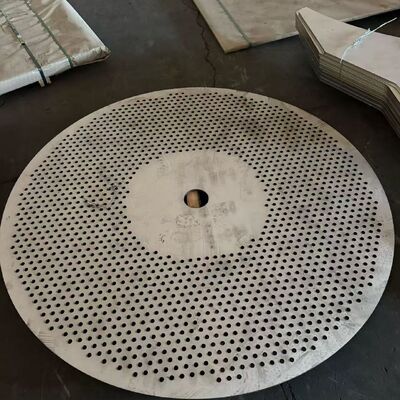

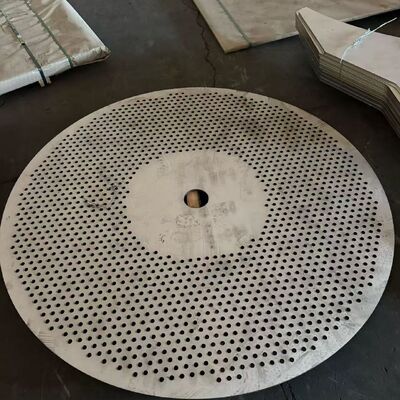

EN 1.4462 & 1.4410 Duplex Stainless Steel Plate Laser Cutting Thickness 2.0 - 80.0mm With Smooth Edge

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x제품 상세 정보

| 제품 | 스테인레스 강판 | 등급 | 2205 2507 |

|---|---|---|---|

| 표준 크기 | 1500*6000mm | 두께 | 2.0 - 40.0mm |

| 상표 | 티스코 바오스틸 포스코 리스코 | 선적항 | 상하이항 |

| MOQ | 500kg | 포장 | 나무 팔레트 + 방수 종이 |

| 강조하다 | Duplex stainless steel plate laser cutting,EN 1.4462 stainless steel plate,1.4410 duplex steel smooth edge |

||

제품 설명

EN 1.4462 & 1.4410 Duplex Stainless Steel Plate Laser Cutting Thickness 2.0 - 80.0mm With Smooth Edge

Products Specification

| Products | Duplex Stainless Steel Plate |

| Thickness | 1.0- 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

EN 1.4462 & 1.4410 Duplex Stainless Steel Plate – Precision Laser Cutting, Thickness 2.0–80.0 mm, Smooth Edge Guaranteed

High-Performance Duplex Plates, Expertly Cut for Demanding Applications

We specialize in CNC laser cutting of EN 1.4462 (Duplex 2205) and EN 1.4410 (Super Duplex 2507) stainless steel plates in thicknesses ranging from 2.0 mm to 80.0 mm, delivering smooth, burr-free edges with tight dimensional tolerances. Whether you require simple blanks or complex components for oil & gas, marine, chemical processing, or desalination systems, our advanced cutting technology ensures your parts are fabrication-ready—often without secondary finishing.

Backed by full material traceability and compliance with EN 10088-2, ASTM A240, NORSOK M-650 (for 1.4410), and other global standards, our service combines metallurgical integrity with precision engineering.

Material Overview: EN 1.4462 vs. EN 1.4410

| Property | EN 1.4462 (Duplex 2205) | EN 1.4410 (Super Duplex 2507) |

|---|---|---|

| UNS Equivalent | S32205 / S31803 | S32750 |

| Type | Standard Duplex | Super Duplex |

| Microstructure | ~50% Austenite + 50% Ferrite | Balanced dual-phase (optimized for strength & corrosion) |

| PREN (Pitting Resistance)* | 34–38 | 40–45 |

| Yield Strength (Rp0.2) | ≥450 MPa | ≥550 MPa |

| Tensile Strength (Rm) | 620–750 MPa | 750–950 MPa |

| Max Service Temp | ~300°C | ~280°C |

| Key Alloying Elements | Cr 22%, Ni 5.5%, Mo 3.2%, N 0.17% | Cr 25%, Ni 7%, Mo 4%, N 0.28% |

| Typical Applications | Chemical tanks, heat exchangers, pipelines | Subsea manifolds, seawater systems, FGD scrubbers |

*PREN = %Cr + 3.3×%Mo + 16×%N — higher = better pitting resistance.

Laser Cutting Capabilities: 2.0–80.0 mm with Smooth Edges

Cutting thick duplex stainless steel requires specialized expertise to avoid microstructural degradation and edge defects. Our hybrid approach ensures quality across the full thickness range:

| Thickness Range | Cutting Technology | Edge Quality | Notes |

|---|---|---|---|

| 2.0 – 25.0 mm | High-power fiber laser | ISO 9013 Class 2 | Ultra-smooth, vertical kerf; minimal dross |

| 25.1 – 50.0 mm | High-precision CO₂ laser | ISO 9013 Class 2–3 | Clean cut with slight taper (<2°); nitrogen assist |

| 50.1 – 80.0 mm | Advanced oxygen-assisted CO₂ laser + post-processing | ISO 9013 Class 3 | Smooth finish achieved via optimized parameters and light grinding if required |

✅ All cuts use high-purity nitrogen or argon assist gas to prevent oxidation

✅ Heat input is tightly controlled to avoid sigma/chi phase formation in the HAZ

✅ Edges are smooth enough for direct welding or assembly in most cases

✅ Heat input is tightly controlled to avoid sigma/chi phase formation in the HAZ

✅ Edges are smooth enough for direct welding or assembly in most cases

Technical Specifications

| Feature | Details |

|---|---|

| Material Grades | EN 1.4462 (X2CrNiMoN22-5-3), EN 1.4410 (X2CrNiMoN25-7-4) |

| Thickness Range | 2.0 mm to 80.0 mm |

| Standard Plate Sizes | 2000×6000 mm, 2500×6000 mm, 3000×12000 mm (custom blanks available) |

| Surface Finish | Hot-rolled (standard), pickled & passivated (optional) |

| Dimensional Tolerance | ±0.1 mm (≤10 mm), ±0.2 mm (10–30 mm), ±0.5 mm (>30 mm) |

| Edge Roughness (Ra) | ≤12.5 µm (typically 6.3–10 µm for <25 mm) |

| Certifications | EN 10204 3.1/3.2, ASTM A240, NORSOK M-650 (1.4410), PMI traceable |

| File Formats Accepted | DXF, DWG, STEP, IGES, PDF (with dimensions) |

Why Smooth Edges Matter in Duplex Steels

Rough or oxidized cut edges can:

- Act as initiation sites for pitting or crevice corrosion

- Require time-consuming grinding before welding

- Compromise fatigue performance in dynamic loads

Our smooth-edge laser process eliminates these issues by:

- Preventing scale formation through inert gas shielding

- Minimizing recast layer and micro-cracks

- Maintaining the alloy’s natural passive layer integrity

This is especially critical for EN 1.4410, which is often used in seawater, sour gas, or high-chloride environments where surface quality directly impacts service life.

Applications by Industry

| Industry | Typical Components (Laser-Cut from 1.4462 / 1.4410) |

|---|---|

| Oil & Gas | Christmas trees, manifolds, choke valves, flowlines |

| Offshore & Marine | Riser clamps, seawater piping, ballast system parts |

| Chemical Processing | Reactor internals, distillation trays, acid storage vessels |

| Desalination | High-pressure RO housings, brine heater tubesheets |

| Power & Energy | Flue gas desulfurization (FGD) ducts, heat exchanger plates |

| Pulp & Paper | Bleach plant towers, digester components |

Quality Assurance Process

- Material Verification: All plates sourced from certified mills with full MTRs

- PMI Testing: Optional XRF/OES verification before and after cutting

- Process Control: Laser parameters logged per job (power, speed, gas pressure)

- Inspection: Visual + dimensional checks per ISO 9013; UT available for >40 mm

- Finishing: Optional pickling/passivation or light grinding for ultra-smooth edges

Ordering Information

- Minimum Order: 1 piece

- Lead Time: 5–15 working days (depending on thickness and complexity)

- Secondary Services: Beveling, marking (laser/engraving), protective film, export packaging

- Global Shipping: FOB, CIF, or DDP options available

Simply send your CAD drawing, specify EN 1.4462 or 1.4410, thickness, and quantity—we’ll handle the rest.

Sustainability & Lifecycle Value

EN 1.4462 laser cutting, EN 1.4410 stainless steel plate, duplex steel smooth edge cut, 2mm to 80mm laser cut duplex, Super Duplex 2507 plate cutting, 1.4410 smooth edge laser, thick duplex stainless steel fabrication, PREN 40 plate laser cut, offshore grade stainless steel parts, CNC laser cut 1.4462 1.4410.

추천된 제품