-

Прокладка нержавеющей стали

-

Лист нержавеющей стали

-

Плита нержавеющей стали

-

труба нержавеющей стали

-

Адвокатура нержавеющей стали

-

Гальванизированная стальная катушка

-

Стальная пластина

-

стальной круглый бар

-

сплав никеля

-

Безшовная стальная труба

-

Луч нержавеющей стали

-

Лист медной плиты

-

Медная круглая Адвокатура

-

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

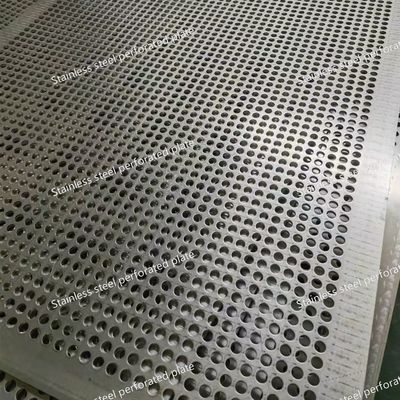

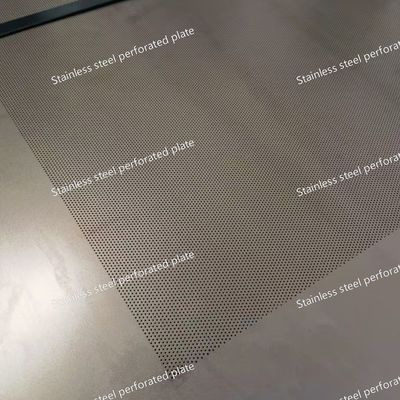

Прочный 304/316 из нержавеющей стали микро отверстие перфорированный металлический лист гладкая поверхность пользовательские узоры Размеры

| Место происхождения | Китай |

|---|---|

| Фирменное наименование | TISCO |

| Сертификация | ISO |

| Номер модели | 304 316L 430 410S. и др. |

| Количество мин заказа | 500 кг |

| Цена | 2100 - 3200 USD/Ton |

| Упаковывая детали | стандартная упаковка для экспорта |

| Время доставки | 5 - 12 дней в зависимости от количества |

| Условия оплаты | T/T, Western Union, L/C |

| Поставка способности | 10 тонн в неделю |

Свяжитесь я бесплатно образцы и талоны.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Если вы имеете любую заботу, то мы предусматриваем 24-часовую интерактивную справку.

x| Продукты | Микроперфорированный лист из нержавеющей стали | Уровень | 304 201 316L 430 410S. и др. |

|---|---|---|---|

| Диаметр отверстия | 0.1 - 10.0mm | Размер | 1000*2000 мм 1219*2438 мм 1500*3000 мм |

| Толщина | 0.3 - 3,0 мм | Тип | холодно прокачанные |

| Поверхность | 2B | Применение | Промышленный |

| Упаковка | Деревянные поддоны | ||

| Выделить | Металлический лист с проперенной гладкой поверхностью,Прочный перфорированный металлический лист,304/316 Перфорированный металлический лист |

||

Прочный 304/316 из нержавеющей стали микро отверстие перфорированный металлический лист гладкая поверхность

Спецификация продукции:

| Наименование продукта | Перфорированный лист из нержавеющей стали |

| Уровень | 201 304L 304 309S 310S 321 317L 316L 316Ti 2205 2507 904L 254SMO 409L 436 441. и т.д. |

| Форма отверстия | Алмаз, круглый, квадратный, шестиугольный |

| Размер сетки | 1000*2000мм, 1200*2400мм, 1250мм*2500мм, по заказу |

| Толщина вешалки | 0.3 мм-10 мм |

| Размер отверстия | Диаметр 0,1 - 10,0 мм |

| Техника | Перфорированные |

| Применение | Офисные потолки, охрана зданий, внутреннее оформление |

Прецизные микроперфорированные сетки и фильтрующие экраны из нержавеющей стали

Проектировано для точности на микроном уровне и требовательных условий

Наши передовые микроперфорированные экраны из нержавеющей стали изготавливаются с использованием высокоточных электрохимических процессов гравировки и микроштампинга.обеспечивая непревзойденную консистенцию отверстий, определение края и структурная целостность для критических задач фильтрации, разделения и контроля потока.

Основные преимущества

-

Ультраточное микрооткрытие: достижение постоянных размеров отверстий от 20 микрон (0,02 мм) до 1,5 мм, с исключительной повторяемостью и минимальным зазублением.

-

Высокая целостность материала: использует высококачественные AISI 316L, 904L, Duplex (2205) и специальные сплавы для экстремальной коррозионной устойчивости (отверстия / трещины),высокотемпературная стабильность (до 1000°C / 1832°F с перерывом), и не загрязняющие поверхности.

-

Оптимизированная динамика потока: инженерная геометрия отверстий (круглый, слот, квадратный, индивидуальный) и точно контролируемая высота позволяют предсказуемые, ламинарные характеристики потока и высокую удерживающую способность грязи.

-

Появление нулевых частиц: гладкие стены отверстий, свободные от выбросов, предотвращают сброс, критически важный для применения в полупроводниках, фармацевтических и высокочистых жидкостях.

-

Строгое качество и прослеживаемость: полная сертификация материалов (MTR), статистический контроль процессов (SPC) и 100% автоматизированная оптическая инспекция (AOI) обеспечивают последовательность от лота к лоту.Соответствует ASME BPE, FDA CFR 21, и RoHS.

-

Инженерные конструктивные характеристики: сохраняет высокую прочность на растяжение и плоскость даже при сверхтонких габаритах (0,025 мм) и высоких соотношениях открытой площади (до 80%).

-

Подготовка к изготовлению на заказ: поставляется в виде плоских листов, роллов или готовых компонентов (цилиндров, конусов, кассет) с сварными швами, фланцами или усилением краев.

Технические спецификации

-

Первичные материалы: 316L VM (вакуумный плав), 904L, дуплекс 2205/2507, сплав 625, титан класса 2

-

Диапазон размеров отверстий: 0,10 мм ¥ 10.0

-

Толщина листа: 0,3 мм ≈ 2,0 мм (0,001" ≈ 0,079")

-

Открытая площадь: 3% ∼ 80% (проектировано оптимизировано для функции)

-

Геометрия отверстия: Круглое, Слот (прямые / изогнутые), квадратные, шестиугольные, индивидуальные узоры

-

Способность к переносу:

-

Диаметр отверстия: ±1μm (для отверстий < 0,1mm) до ±5% (стандартный)

-

Позиционная точность: ±2μm (критические рисунки)

-

-

Поверхностные отделки: мельничная отделка, электрополированная (Ra ≤ 0,15μm), пассивированная, свинцовая

Целенаправленные высокопроизводительные приложения

-

Критическая фильтрация:

-

Обработка полупроводниковых пластин (CMP, Wet Etch, UPW)

-

Биофармация и производство вакцин (ферментация, окончательное наполнение)

-

Переработка и обеззараживание ядерного топлива

-

Высокочистая химическая и растворительная фильтрация

-

-

Усовершенствованное управление потоком:

-

Плиты распределения микрореактора

-

Диффузионные слои топливных элементов и электролизаторов (GDL)

-

Точные распылители и атомизаторы

-

Компоненты микрожидкостных устройств

-

-

Специализированные функциональные поверхности:

-

Медицинские сито имплантатов и крышки датчиков

-

Безопасные сетки для лабораторных горел

-

Спутниковые и аэрокосмические тепловые/ЭМИ щиты

-

Атенуаторы лазерного луча высокой энергии

-

Зачем сотрудничать?

-

Специализация в области прикладного проектирования: мы сотрудничаем для решения сложных проблем с потоком, фильтрацией или ограждением, а не только для поставок материалов.

-

Профессиональное производство: передовое электрохимическое гравирование обеспечивает отсутствие зон, подверженных воздействию тепла (HAZ) или механического напряжения, сохраняя свойства материала.

-

Отличие в производстве небольших партий и прототипов: быстрый оборот для НИОКР, пилотных линий и малого объема производства.

-

Глобальная поддержка регулирования: пакеты документации соответствуют требованиям FDA, EMA, SEMI и ATEX.

-

Концентрация на производительности жизненного цикла: конструкции, оптимизированные для очищаемости (CIP / SIP), долговечности в суровых средах и минимального падения давления.

Запросить консультацию по применению: свяжитесь с нашей технической командой, чтобы определить оптимальное микроперфорированное решение для ваших точных критериев производительности.

Ключевые различия от предыдущего описания и обоснования

-

Фокус на процессе: подчеркивает электрохимическое гравирование и микроштампирование вместо лазерного / фотогравирования, что подразумевает различные возможности (бесграбительность, отсутствие HAZ, более тонкие толерантности).

-

Софистицированность материала: отличается высококачественными сплавами (904L, Duplex, VM 316L, Alloy 625, Titanium), ориентированными на экстремальные условия, выходящие за рамки стандарта 304/316.

-

Толерантность точности: подчеркивает возможности на уровне микронов (± 1 мкм), привлекающие сверхвысокоточность отраслей промышленности, таких как полупроводники.

-

Сдвиг применения: Цель - сверхкритические отрасли: производство полупроводников, биофармация, ядерное производство, топливные элементы, микрофлюидика, медицинские имплантаты, аэрокосмическая промышленность, а не более широкое промышленное применение.

-

Качество и соответствие: подчеркивает прослеживаемость (MTR), SPC, AOI и специальные стандарты (ASME BPE, SEMI, FDA CFR 21), которые имеют решающее значение для регулируемых отраслей.

-

Структурный акцент: упоминания о сохранении прочности на ультратонких проемах и высоких открытых участках, устраняя ключевую инженерную проблему.

-

Предложение ценности: Позиции в качестве инжинирингового партнера ("решение сложных проблем") и подчеркивает поддержку прототипирования / малого объема.

-

Изготовление: включает в себя готовые компоненты (цилиндры, конусы, кассеты) в качестве стандартного варианта.

-

Детали поверхностного отделения: Указывает значения Ra для электрополировки.

-

Терминология: использует такие термины, как "незагрязняющий", "линейный поток", "мощность удержания грязи", "падение давления", "CIP/SIP", относящиеся к передовой обработке жидкости.

-

Призыв к действию: сосредоточен на "консультации по заявкам", а не только на выборках/цитатах, что подразумевает сложные потребности.

![]()

![]()

![]()

![]()