-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Hot Rolled and Forged Hastelloy C-22 Round Bar Black and Bright Polished Bar in Custom Length

| Lugar de origem | CHINA |

|---|---|

| Marca | DELTA |

| Certificação | ISO |

| Número do modelo | Hastelloy C-22 |

| Quantidade de ordem mínima | 10 kg |

| Preço | 40 - 50 USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias com base na quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 3 toneladas por semana |

| Produtos | Barra redonda Hastelloy C-22 | Nota | Hastelloy C22 |

|---|---|---|---|

| Diâmetro | 10 - 350mm | Comprimento | corte por encomenda de qualquer comprimento conforme pedido |

| Padrão | ASTM EN | Serviço | CORTE |

| Porta de carregamento | Porto de Xangai | Superfície | brilhante, preto |

| Destacar | Hastelloy C-22 round bar,Hot rolled nickel alloy bar,Forged Hastelloy black polished bar |

||

Hot Rolled and Forged Hastelloy C-22 Round Bar Black and Bright Polished Bar in Custom Length

More Specification Informations

| Products Name | Hastelloy C22 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hot Rolled and Forged Hastelloy C-22 Round Bar: Black and Bright Polished Bar in Custom Length

Premium Corrosion Resistance for Demanding Applications

Our Hastelloy C-22 round bars represent the pinnacle of nickel-chromium-molybdenum-tungsten alloys, engineered to deliver exceptional performance in the most aggressive corrosive environments. Available in both hot rolled and forged conditions, and in your choice of black (as-supplied) or bright polished surface finishes, we provide the material solution tailored to your specific technical and aesthetic requirements.

Product Forms & Availability

-

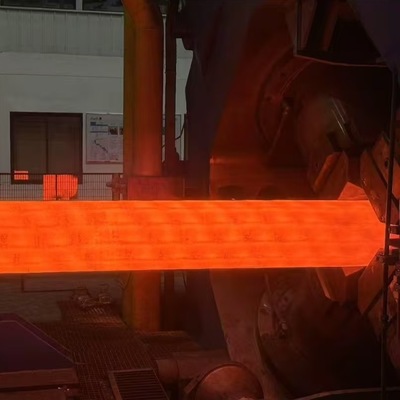

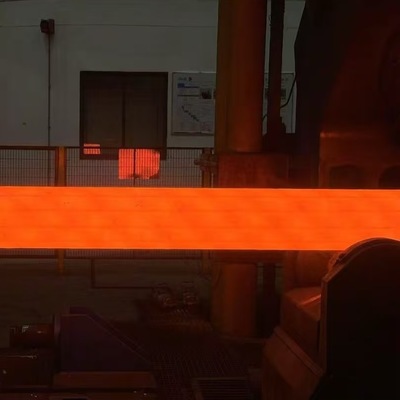

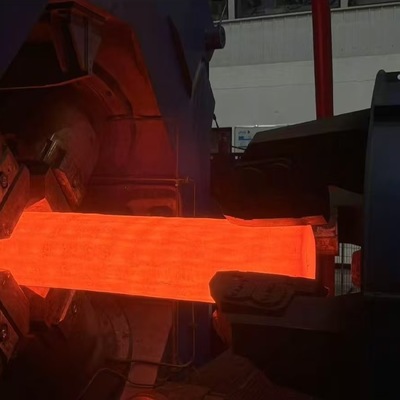

Hot Rolled Round Bars: Cost-effective solution with good mechanical properties, suitable for a wide range of general corrosion applications.

-

Forged Round Bars: Superior mechanical strength, grain structure, and directional properties achieved through the forging process. Ideal for high-integrity components like valve stems, fasteners, and pump shafts subject to high stress.

-

Custom Lengths: We specialize in supplying round bars cut to your exact specifications, minimizing waste and reducing your machining time and cost.

Surface Finishes

-

Black Bar: Supplied in a descaled, as-rolled or as-forged condition. This economical finish is perfect for parts that will undergo subsequent machining or where surface appearance is not critical.

-

Bright Polished Bar: Cold drawn and polished to a smooth, shiny finish. This offers excellent dimensional accuracy, a superior surface appearance, and is often used for applications where a clean, finished surface is required with minimal post-processing.

Key Features & Material Advantages of Hastelloy C-22

-

Exceptional, All-Around Corrosion Resistance: Hastelloy C-22 offers outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking.

-

Versatile Oxidizing and Reducing Media Capability: It performs excellently in both oxidizing and reducing environments, including those containing chlorides.

-

Superior Resistance to Wet Chlorine and Mixed Acids: An ideal choice for handling sulfuric acid, nitric acid, acetic acid, and other aggressive chemical media.

-

Excellent Weldability: Hastelloy C-22 is readily welded using common techniques and shows low susceptibility to weld zone degradation.

-

High Thermal Stability: Maintains its properties over a wide temperature range.

Typical Chemical Composition (Weight %)

| Element | Ni (Nickel) | Cr (Chromium) | Mo (Molybdenum) | W (Tungsten) | Fe (Iron) | Co (Cobalt) | C (Carbon) | Mn (Manganese) | Si (Silicon) | P (Phosphorus) | S (Sulfur) | V (Vanadium) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C-22 | Bal. | 20 - 22.5 | 12.5 - 14.5 | 2.5 - 3.5 | 2.0 - 6.0 | 2.5 max | 0.015 max | 0.50 max | 0.08 max | 0.02 max | 0.02 max | 0.35 max |

Mechanical Properties (Typical at Room Temperature)

| Condition | Tensile Strength | Yield Strength (0.2% Offset) | Elongation (%) |

|---|---|---|---|

| Annealed | 110 ksi (758 MPa) min | 51 ksi (352 MPa) min | 45% min |

Industries & Applications

Our Hastelloy C-22 round bars are specified across a wide range of critical industries:

-

Chemical Processing: Reactors, vessels, heat exchangers, agitators, and piping systems.

-

Pollution Control: Flue Gas Desulfurization (FGD) systems, scrubbers, and ducting.

-

Pharmaceutical & Fine Chemical: Equipment requiring high purity and resistance to corrosive cleaning agents.

-

Pulp & Paper Industry: Digesters and bleach plants.

-

Waste Treatment: Incinerators and waste handling systems.

-

Marine & Offshore: Components exposed to seawater and saline atmospheres.

Contact us today to discuss your project requirements and receive a competitive quote for your custom-length Hastelloy C-22 round bars. Our technical experts are ready to assist you in selecting the optimal form and finish for your application.

![]()

![]()

![]()

![]()