-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

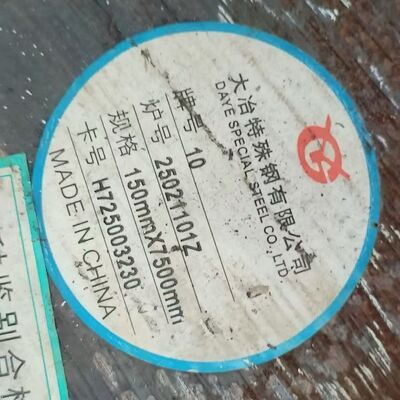

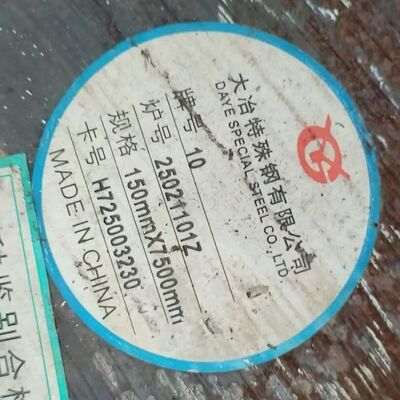

High-Strength Alloy Structural Steel Round Bar – Precision Ground & Heat Treated

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| Products Name | Alloy Steel Round Bar | Diameter | 10 - 450mm |

|---|---|---|---|

| Length | 6m | Tech | Hot rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

High-Strength Alloy Structural Steel Round Bar – Precision Ground & Heat Treated

Products Specification

|

Products Name |

Alloy Steel Round Bar |

|

Diameter |

20 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,B16,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Product Overview

Key Features & Benefits

- ✅ High Yield & Tensile Strength: Achieves yield strengths up to 900–1200 MPa (depending on grade and heat treatment).

- ✅ Precision Ground Surface: Surface roughness as low as Ra 0.4–0.8 µm, ensuring excellent fit and reduced friction in dynamic assemblies.

- ✅ Uniform Hardness & Microstructure: Full through-hardening with minimal distortion due to controlled quenching and tempering cycles.

- ✅ Tight Dimensional Tolerances: Diameter tolerance up to h6/h7 per ISO 286, suitable for direct machining or press-fit applications.

- ✅ Enhanced Fatigue Resistance: Ideal for cyclic loading environments (e.g., crankshafts, connecting rods).

- ✅ Traceable Certification: Mill test reports (MTRs) provided per EN 10204 3.1, including chemical composition and mechanical test data.

Common Grades & Specifications

| Grade (GB/T 3077) | Equivalent (AISI/SAE) | Chemical Composition (Typical %) | Typical Applications |

|---|---|---|---|

| 40Cr | 5140 | C: 0.37–0.44, Cr: 0.80–1.10 | Gears, axles, bolts |

| 42CrMo4 | 4140 | C: 0.38–0.45, Cr: 0.90–1.20, Mo: 0.15–0.25 | High-stress shafts, drill collars |

| 35CrMo | 4135 | C: 0.32–0.40, Cr: 0.80–1.10, Mo: 0.15–0.25 | Turbine rotors, fasteners |

| 20CrMnTi | 8620 | C: 0.17–0.23, Cr: 1.00–1.30, Mn: 0.80–1.10, Ti: 0.04–0.10 | Case-hardened gears |

| 38CrMoAl | — | C: 0.35–0.42, Cr: 1.35–1.65, Mo: 0.08–0.15, Al: 0.70–1.10 | Nitriding shafts, wear-resistant parts |

Mechanical Properties After Heat Treatment (Quenched & Tempered)

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Impact Toughness (J @ -20°C) |

|---|---|---|---|---|---|

| 40Cr | 980–1100 | ≥785 | ≥9 | 285–341 | ≥47 |

| 42CrMo4 | 1080–1250 | ≥930 | ≥10 | 302–363 | ≥54 |

| 35CrMo | 930–1080 | ≥785 | ≥10 | 269–321 | ≥63 |

| 38CrMoAl | 930–1030 | ≥785 | ≥12 | 229–285 | ≥78 |

Manufacturing Process

- Melting & Casting: Electric arc furnace (EAF) + LF refining + VD degassing for ultra-clean steel.

- Hot Rolling: Continuous rolling to near-net shape with controlled cooling.

- Straightening & Stress Relieving: To minimize residual stresses.

- Precision Grinding: Centerless or between-centers grinding to achieve h6/h7 tolerances and smooth surface.

- Heat Treatment:

- Austenitizing at 840–880°C (grade-dependent)

- Oil or polymer quenching

- Tempering at 500–650°C for desired strength-toughness balance

- Final Inspection: Ultrasonic testing (optional), hardness verification, dimensional check, and visual inspection.

Dimensional Range & Availability

| Parameter | Range |

|---|---|

| Diameter | 10 mm – 300 mm |

| Length | 2,000 mm – 6,000 mm (custom lengths available) |

| Surface Finish | Ground (Ra ≤ 0.8 µm), optional polished |

| Tolerance (Diameter) | h6 (±0.007 mm for Ø20 mm), h7 standard |

| Straightness | ≤0.2 mm/m |

| Packaging | Bundled with anti-rust oil, wooden pallets, seaworthy export packing |

Why Choose Our Precision-Ground High-Strength Alloy Steel Bars?

- Consistency: Batch-to-batch uniformity ensured by integrated production control from melt to finish.

- Certification: Full compliance with ISO 9001, IATF 16949 (for automotive), and material traceability via heat number.

- Customization: We offer tailored heat treatment profiles (e.g., higher toughness for cryogenic use or elevated hardness for wear resistance).

- Global Delivery: Ready stock for common sizes; lead time 15–30 days for custom orders.

- Technical Support: Our metallurgical engineers assist with grade selection, processing advice, and failure analysis.

Applications Across Industries

- Automotive: Camshafts, steering knuckles, suspension components

- Aerospace: Landing gear pins, actuator rods

- Energy: Downhole tools, pump shafts, turbine spindles

- Construction Machinery: Excavator pins, hydraulic cylinders

- Industrial Equipment: High-load rollers, spindle bars, coupling hubs

Quality Assurance & Testing

- Chemical Analysis: Spectrometry (OES) for precise elemental control

- Tensile Testing: Per GB/T 228.1 or ASTM E8

- Charpy Impact Test: At room and sub-zero temperatures

- Hardness Mapping: Cross-section verification

- Non-Destructive Testing (NDT): Optional ultrasonic (UT) or magnetic particle inspection (MPI) for critical applications

Ordering Information

- Steel grade (e.g., 42CrMo4 / AISI 4140)

- Diameter and length

- Required tolerance class (h6, h7, etc.)

- Heat treatment condition (Q+T, normalized, etc.)

- Surface finish requirement

- Quantity and delivery terms (FOB, CIF, etc.)

Sustainability & Compliance

Conclusion