-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

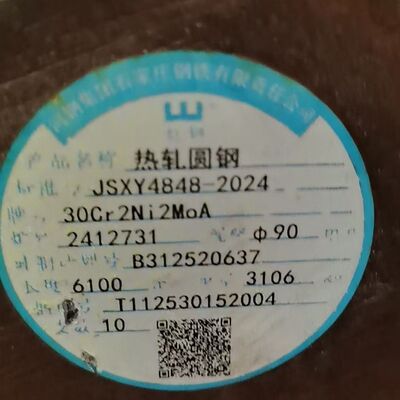

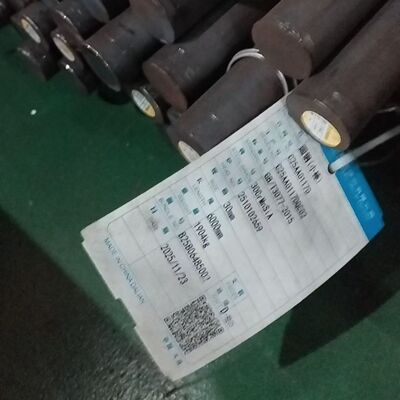

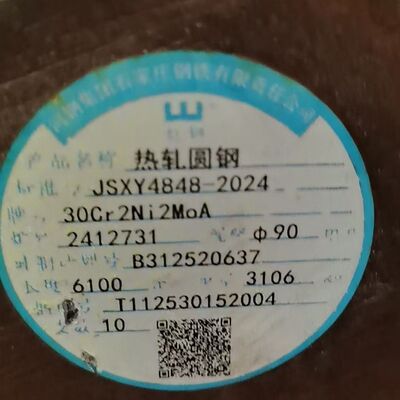

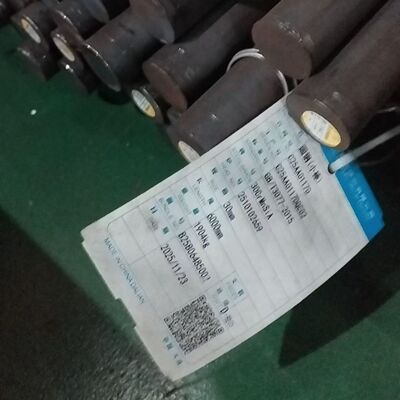

Cold Drawn Alloy Steel Round Bar for Mechanical Engineering Applications

試供品およびクーポンのための私に連絡しなさい。

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 製品名 | 合金鋼丸棒 | 直径 | 10~450mm |

|---|---|---|---|

| 長さ | 6m | 技術 | 熱間圧延 |

| サービス | 切断 | MOQ | 1トン |

| 積み込み口 | 上海港 | 標準 | ASTM EN GB |

Cold Drawn Alloy Steel Round Bar for Mechanical Engineering Applications

Products Specification

|

Products Name |

Alloy Steel Round Bar |

|

Diameter |

20 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,B16,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Product Overview

Key Advantages of Cold Drawing

- ✅ Improved Surface Finish: Smooth, scale-free surface with roughness as low as Ra 0.8–1.6 µm

- ✅ Tighter Dimensional Tolerances: Up to h8/h9 standard (custom h7 available) per ISO 286

- ✅ Enhanced Mechanical Properties: Increased tensile and yield strength due to strain hardening (up to 15–25% higher than hot-rolled equivalents)

- ✅ Excellent Straightness: Typically ≤ 0.3 mm/m, reducing alignment issues during assembly

- ✅ Consistent Cross-Section: Uniform diameter along the entire length

- ✅ Clean & Ready-to-Use: No decarburization or oxide scale—ideal for direct CNC machining or grinding

Common Grades & Chemical Composition

| Grade (GB/T 3077) | AISI/SAE Equivalent | Key Alloying Elements (Typical %) | Primary Use Case |

|---|---|---|---|

| 20Cr | 5120 | C: 0.17–0.24, Cr: 0.70–1.00 | Case-hardened pins, small gears |

| 40Cr | 5140 | C: 0.37–0.44, Cr: 0.80–1.10 | Shafts, bolts, medium-stress parts |

| 42CrMo4 | 4140 | C: 0.38–0.45, Cr: 0.90–1.20, Mo: 0.15–0.25 | High-strength axles, tool holders |

| 35CrMo | 4135 | C: 0.32–0.40, Cr: 0.80–1.10, Mo: 0.15–0.25 | Connecting rods, heavy-duty fasteners |

| 20CrMnTi | 8620 | C: 0.17–0.23, Cr: 1.00–1.30, Mn: 0.80–1.10, Ti: 0.04–0.10 | Carburized transmission gears |

All grades feature low sulfur (S ≤ 0.025%) and phosphorus (P ≤ 0.025%) content for improved ductility and machinability.

Mechanical Properties (As Cold Drawn)

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Typical Machinability |

|---|---|---|---|---|---|

| 20Cr | 540–690 | ≥345 | ≥16 | 156–207 | Excellent |

| 40Cr | 785–930 | ≥590 | ≥12 | 217–269 | Good |

| 42CrMo4 | 850–1000 | ≥655 | ≥12 | 241–285 | Moderate (requires sharp tools) |

| 35CrMo | 735–885 | ≥540 | ≥13 | 207–255 | Good |

| 20CrMnTi | 590–735 | ≥390 | ≥15 | 163–217 | Excellent (pre-carburizing) |

Dimensional Specifications

| Parameter | Standard Range | Custom Options Available |

|---|---|---|

| Diameter | 6 mm – 100 mm | Up to 120 mm (subject to grade) |

| Length | 2,000 – 6,000 mm | Cut-to-length (±1 mm tolerance) |

| Diameter Tolerance | h9 (standard), h8 (common), h7 (on request) | Per ISO 286 or customer drawing |

| Straightness | ≤ 0.3 mm per meter | ≤ 0.15 mm/m (precision grade) |

| Surface Roughness | Ra 0.8–1.6 µm | Ra ≤ 0.4 µm (with additional polishing) |

| Packaging | Oiled, bundled, plastic-wrapped on wooden pallets | VCI paper, export crates |

Manufacturing Process

- Hot-Rolled Bar Input: Sourced from continuously cast, fully killed steel with ultrasonic inspection.

- Pickling & Phosphating: Removes scale and prepares surface for cold drawing.

- Cold Drawing: Passed through a die at room temperature to reduce diameter and improve properties.

- Straightening: Precision roller or stretch-straightening for optimal geometry.

- Final Inspection: Dimensional checks, visual surface review, and batch testing.

- Optional: Stress relieving (~550–650°C) to minimize distortion during machining (available on request).

Why Choose Cold Drawn Over Hot-Rolled or Ground Bars?

| Feature | Hot-Rolled Bar | Cold Drawn Bar | Precision Ground Bar |

|---|---|---|---|

| Surface Finish | Rough, scaled | Smooth, clean | Mirror-like (Ra < 0.8 µm) |

| Dimensional Tolerance | ±0.5 mm or worse | ±0.05–0.1 mm | ±0.01 mm (h6/h7) |

| Strength | Standard | Enhanced (strain hardened) | As-heat-treated |

| Machining Allowance | High | Low to none | Minimal or none |

| Cost Efficiency | Low material cost | Balanced performance/cost | Higher cost, high precision |

| Best For | Structural frames | Mass-produced precision parts | Critical-fit components |

Applications in Mechanical Engineering

- Automotive: Transmission shafts, steering columns, valve stems

- Industrial Machinery: Pump shafts, guide rods, eccentric cams

- Agricultural Equipment: PTO shafts, linkage pins

- Hydraulics & Pneumatics: Piston rods, cylinder spindles

- Robotics: Joint axes, actuator components

- Tooling: Die holders, ejector pins, mold cores

Quality Assurance

- Full mill test reports (MTRs) per EN 10204 3.1

- ISO 9001:2015 certified production

- Batch traceability via heat number

- Optional ultrasonic testing (UT) or magnetic particle inspection (MPI) for critical applications

- Compliance with RoHS and REACH regulations

Ordering Guidelines

- Desired steel grade (e.g., 42CrMo4 / AISI 4140)

- Required diameter and length

- Tolerance class (e.g., h8)

- Surface finish preference

- Quantity and delivery terms

- Special requirements (e.g., stress relief, cut-to-length, certification level)

Conclusion

![]()

![]()

![]()

![]()