-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

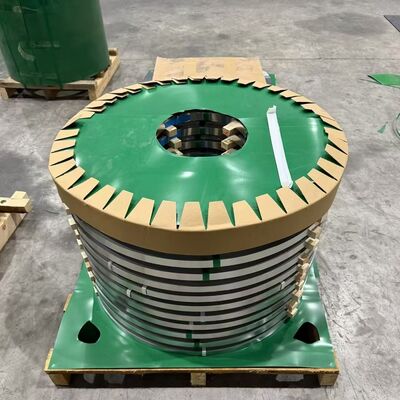

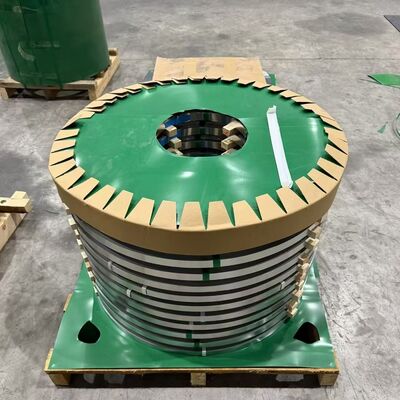

精密型ステンレス鋼のストライプ グレード SUS304, 304, 1.4301 SS ストライプコイル EN10204-3.1 認定

試供品およびクーポンのための私に連絡しなさい。

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 製品 | ステンレス鋼のストリップ | 厚さ | 0.1-3.0mm |

|---|---|---|---|

| 幅 | 1219mm以内 | MOQ | 20キログラム |

| 学年 | 200シリーズ300シリーズ300シリーズ | 表面 | BA 2B No.4 HL 8K No.1 |

| 標準 | astm en gb jis | パッキング | 木製のフレームと防水紙 |

| ハイライト | SUS304ステンレス鋼のストリップ,304ステンレス鋼のストリップのコイル,EN10204-3.1 認証された鋼筋 |

||

精密型ステンレス鋼のストライプ グレード SUS304, 304, 1.4301 SS ストライプコイル EN10204-3.1 認定

| 製品 | ステンレス・スティール・ストライプ |

| 厚さ | 0.1-3.0mm |

| 幅 | 最小幅5mm |

| MOQ | 20kg |

| メイングレード | 201 301 304 304L 309S 310S 316L 316Ti 410 420 430 436 439 441 444 440A/B/C2205,2507904LC276400,600,625,926,825... など |

| 表面 | BA 2B |

| スタンダード | ASTM EN GB JIS |

| 梱包 | 木製の枠と防水紙 |

精密なステンレス鋼のストライプ グレード SUS304 / 304 / 14301: EN 10204 3.1 認証のある高品質のSS ストライプコイル

耐腐蝕性,機械的強度,形容性,そして美学的な魅力ステンレス鋼の種類はSUS304 (国際的にはAISI 304またはEN 1.4301としても知られる)最も一般的な信頼性の高いオーステニティックステンレス鋼として注目されていますこのグレードから製造された高精度ステンレス鋼のストライプは,電子機器や自動車から医療機器や食品加工まで,さまざまな分野において不可欠な部品ですローリング形式で供給され,EN 10204 3.1 認証極めて重要なアプリケーションに必要な厳格な品質保証基準を満たしています.

材料概要:SUS304 / 304 / 14301

SUS304は日本工業標準 (JIS) 名称であり,304はアメリカ鉄鋼研究所 (AISI) 名称であり,1.4301 は DIN/EN システムによる欧州規格 (EN) の番号です異なる命名慣例にもかかわらず,三つは同じ基礎合金組成を指します.

- クロム (Cr):18~20%

- ニッケル (Ni):8~10.5%

- 炭素 (C):≤0.07%

- マンガン (Mn):≤2.0%

- シリコン (Si):≤1.0%

- リンゴ (P):≤0.045%

- 硫黄 (S):≤0.030%

- 鉄 (Fe):バランス

この組成は,腐食耐性,溶接性,柔らかさの最適なバランスを提供します.クロム の 存在 は,表面 に 酸化 や 化学 的 攻撃 に 対し て 保護 する 消極 的 な 酸化 層 を 形成 し ますニッケルがアウステニット構造を安定させ,冷凍温度でも優れた強度を確保します.

精密型不?? 鋼帯:定義と特徴

精密型ステンレス鋼のストライプは,非常に狭い寸法許容量で製造された冷物で,通常厚さ±0.005mm,幅±0.05mm以内です.厚さは通常0.05mmから3.0mm幅は5mmから600mm適用ニーズに基づいてカスタムサイズが利用できます.

精密SUS304ストライプの主要特徴は以下の通りである.

- 表面の質が高い2B,BA (明るく焼却) などの様々な仕上げで入手可能.4消化剤やミラー・ポリスは,最終用途の要求に応じて

- 優れた形容性深い描画,曲がり,スタンプ,および他の二次製造プロセスに理想的です.

- 一貫した機械特性:張力強度は通常515~720MPaで,長さは40~60%で,動的アプリケーションでの信頼性を保証する.

- 磁性でない (焼却状態で):磁気干渉を避ける必要がある電子およびセンサーベースのアプリケーションにとって重要です.

産業間での応用

SUS304精密ストライプの汎用性により,幅広い産業で使用できます.

- エレクトロニクスと電気工学:コンネクタ,ターミナル,バッテリータブ,シールドコンポーネント,柔軟なプリント回路で使用される.

- 自動車:燃料注入システム,センサー,ガシケート,排気コンポーネントで使用されます. 熱循環下で耐久性が重要な場合です.

- 医療機器:バイオコンパティビリティと無菌化性により,外科用機器,埋め込み可能な部品 (負荷を背負わない) および診断機器に最適です.

- 食品・飲料加工衛生基準 (FDA,EC1935/2004など) に準拠し,コンベアベルト,切断刃,包装機械に使用される.

- 航空宇宙と防衛:大気や軽度の化学的暴露に耐性が必要とする非構造的だが高い信頼性の部品に使用される.

EN 10204 3.1 認証:追跡可能性と適合性を確保する

規制されたまたは安全性の重要な用途のための高精度ステンレス鋼のストライプの調達で最も重要な側面の1つは,材料の認証です.標準 EN 10204金属製品に付与される検査書類の種類を定義する.タイプ31商業取引において最も包括的なものです

そしてEN 10204 3.1 証明書製造者によって発行され,以下の内容を含みます.

- 供給された材料の特異熱量またはバッチの実際の試験結果 (化学組成と機械特性)

- 製品が注文の技術仕様 (例えば,ASTM A240,EN 10088-2) に適合していることを確認する.

- 品質管理担当者によって署名された製造者の適合宣言.

- 溶融番号や熱IDまで追跡可能で,サプライチェーン全体で完全な材料追跡が可能になります.

このレベルのドキュメントは,不具合が選択肢でない圧力機器 (PED 2014/68/EU),原子力,医薬品,航空宇宙などの産業で必須です.購入者に,材料が国際基準を満たしていると主張するだけでなく,独立して検証されたことを保証します..

製造プロセスと品質管理

精密SUS304ストライプの製造には複数の段階があります.

- 溶融と鋳造:原材料は電弧炉 (EAF) で溶かされ,アルゴン酸素脱炭化 (AOD) により精密な化学反応を達成するために精製される.

- ホットローリング:高温で薄いコイルに巻く.

- 冷式ロール:室温で実施し,表面の仕上げと機械性能が向上した最終厚さを得る.

- アリリングとピクルング:熱処理は内部ストレスを軽減し,柔らかさを回復し,漬け込みは垢や汚れを除去します.

- 切断と切断:マスターコイルは,顧客の正確な幅に切断され,シートに切ったり,さらに処理したりすることができる (例えば,縁の丸め,緊張のレベル化).

- 検査と試験:化学,張力検査,硬度測定,表面検査,次元検証の 厳格な検査とスペクトロメトリーを経る.

先進的な施設では,自動光学検査 (AOI) システムとレーザーマイクロメーターを使用して マイクロンレベルの精度を保証します.

SUS304 認証された精密ストライプを選択する利点

- 信頼性:一貫したパフォーマンスにより スクラップ率と生産停止時間が減少します

- 規制の遵守:国際基準 (ASTM,JIS,EN,ISO) に準拠し,国際貿易を容易にする.

- サプライチェーン透明性完全な追跡が品質監査とリスク緩和を支援します

- カスタマイズ:製造者は,特定の自動化ラインに合わせて,テンパー (例えば, 1/4H, 1/2H, H),エッジタイプ (割れ目,剥削,丸め) およびパッケージ (水平/垂直コイル,紙を入れ替える) を調整することができます.

![]()

![]()

![]()

![]()