-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

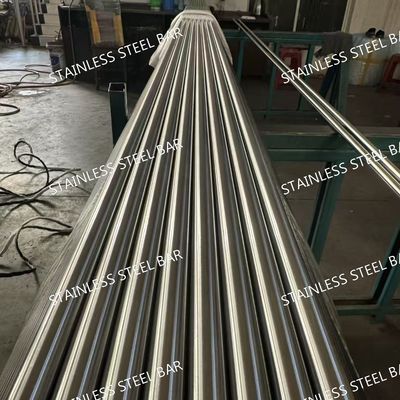

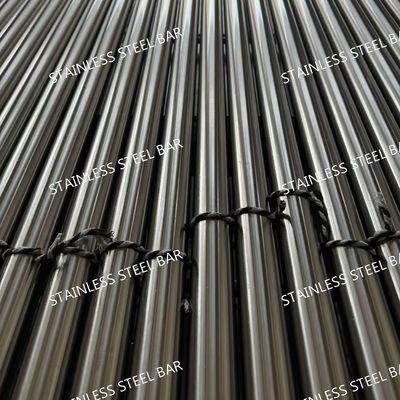

Barra tonda in acciaio inossidabile ASTM A276 Lega 321F Lucidatura brillante H6 H7 H9 H11 H13 Tolleranza

| Luogo di origine | Cina |

|---|---|

| Marca | Delta |

| Certificazione | ISO 9001 |

| Numero di modello | 321F |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 2.4-3.5 USD/Kg |

| Imballaggi particolari | scatola di legno o rivestimento in carta impermeabile |

| Tempi di consegna | 5 - 10 giorni |

| Termini di pagamento | T/T, Western Union |

| Capacità di alimentazione | 50 tonnellate al mese |

| Nome dei prodotti | Barra in acciaio inossidabile 321F | Diametro | 10 - 350mm |

|---|---|---|---|

| Lunghezza | 6m o tagliare qualsiasi lunghezza come richiesta | Superficie | Sottaceti o brillanti |

| Servizio | Taglio | Standard | ASTM Din GB en |

| Altri prodotti | barra rotonda, barra quadrata, barra piatta.etc | Tecnica | Laminato caldo |

| Evidenziare | Tondino di acciaio inossidabile di ASTM A276,Barra in acciaio legato 321F lucidata,Barra in acciaio inossidabile con tolleranza H6 |

||

Barra tonda in acciaio inossidabile ASTM A276 Alloy 321F Lucidatura a specchio Tolleranza H6 H7 H9 H11 H13

Specifiche dei prodotti

| Nome dei prodotti | Barra tonda in acciaio inossidabile 321F |

| Grado |

303,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc |

| Gamma di diametro dei prodotti | φ3mm - φ350mm |

| Lunghezza | 6m/pezzo o taglio a qualsiasi lunghezza su richiesta |

| Superficie | Finitura decapata, finitura lucida |

| Standard | ASTM JIS,GB,DIN EN |

| Servizio | Taglio |

| Altra forma | Quadrata, piatta, esagonale, rotonda.ecc |

| Porto di carico | Porto di Shanghai |

| MOQ | 50 kg |

Barra tonda in acciaio inossidabile ASTM A276 Alloy 321F Lucidatura a specchio Tolleranza H6 H7 H9 H11 H13

Introduzione all'acciaio inossidabile ASTM A276 Alloy 321F

Le barre tonde in acciaio inossidabile ASTM A276 Alloy 321F sono ampiamente utilizzate in applicazioni che richiedono resistenza alle alte temperature e alla corrosione. L'Alloy 321F è una versione stabilizzata al titanio dell'acciaio inossidabile di tipo 304, che lo rende ideale per l'uso in ambienti difficili. La lega mostra un'eccellente resistenza all'ossidazione e alla corrosione intergranulare, soprattutto ad alte temperature. Questo lo rende un materiale ideale per settori come l'aerospaziale, la lavorazione chimica e la produzione di energia.

ASTM A276 è la specifica standard per le barre in acciaio inossidabile utilizzate in applicazioni industriali generali. Il prodotto a barra tonda è tipicamente disponibile in vari gradi di acciaio inossidabile, incluso il popolare grado 321F. La designazione "F" indica che il materiale è stato appositamente progettato per essere più resistente alla criccatura da corrosione sotto tensione e alla sensibilizzazione, soprattutto nelle applicazioni di saldatura.

In questa descrizione del prodotto, esploreremo le proprietà, le applicazioni, le specifiche e le tolleranze delle barre tonde in acciaio inossidabile ASTM A276 Alloy 321F.

Composizione dell'acciaio inossidabile Alloy 321F

La composizione chimica dell'acciaio inossidabile ASTM A276 Alloy 321F è progettata per fornire un'eccellente resistenza all'ossidazione ad alta temperatura e alla carburazione. Di seguito è riportata la composizione tipica dell'acciaio inossidabile 321F:

| Elemento | Contenuto |

|---|---|

| Cromo (Cr) | 17.0 – 19.0% |

| Nichel (Ni) | 9.0 – 12.0% |

| Titanio (Ti) | 5xC min. |

| Manganese (Mn) | 2.0% max. |

| Silicio (Si) | 1.0% max. |

| Carbonio (C) | 0.08% max. |

| Fosforo (P) | 0.045% max. |

| Zolfo (S) | 0.030% max. |

Come indicato, la lega contiene quantità significative di cromo e nichel, che forniscono resistenza alla corrosione, mentre il contenuto di titanio viene aggiunto per prevenire la sensibilizzazione durante la saldatura. Questo assicura che l'acciaio inossidabile mantenga le sue proprietà anche quando esposto ad alte temperature.

Proprietà dell'acciaio inossidabile ASTM A276 Alloy 321F

Proprietà meccaniche

-

Resistenza alla trazione: 515 – 690 MPa (75.000 – 100.000 psi)

-

Resistenza allo snervamento: 205 – 350 MPa (30.000 – 50.000 psi)

-

Allungamento: 40% min (in 50 mm)

-

Durezza: Rockwell B (HRB) 90 max

Queste proprietà rendono la barra tonda in acciaio inossidabile 321F altamente adatta per applicazioni critiche in cui sono richieste elevata resistenza e durata. La sua capacità di resistere all'usura meccanica contribuisce anche alla sua longevità nelle applicazioni industriali.

Proprietà termiche

-

Temperatura massima di esercizio: 870°C (1600°F)

-

Conducibilità termica: 15.1 W/m·K a 100°C

-

Capacità termica specifica: 500 J/kg·K a 25°C

-

Coefficiente di dilatazione termica: 17.3 µm/m·K a 20–100°C

Con le sue eccellenti proprietà alle alte temperature, ASTM A276 Alloy 321F è particolarmente adatto per l'uso in applicazioni in cui i componenti sono soggetti a fluttuazioni di temperatura o calore continuo, come nei settori aerospaziale, petrolchimico e della produzione di energia.

Resistenza alla corrosione

Una delle caratteristiche principali dell'acciaio inossidabile ASTM A276 Alloy 321F è la sua eccezionale resistenza alla corrosione. La lega offre una protezione superiore contro:

-

Ossidazione: Ideale per ambienti ad alta temperatura, l'acciaio inossidabile 321F può resistere all'ossidazione in condizioni fino a 870°C (1600°F).

-

Corrosione intergranulare: Il titanio stabilizza la lega legando il carbonio e previene la precipitazione dei carburi di cromo, che può causare corrosione intergranulare.

-

Resistenza agli acidi: Ha resistenza a molti ambienti acidi, soprattutto ad alte temperature.

Applicazioni della barra tonda in acciaio inossidabile Alloy 321F

Le barre tonde in acciaio inossidabile Alloy 321F sono utilizzate in un'ampia gamma di settori grazie alle loro prestazioni superiori alle alte temperature e alla resistenza alla corrosione. Le applicazioni comuni includono:

-

Aerospaziale: Per componenti del motore, sistemi di scarico e strutture portanti grazie alla sua resistenza alle alte temperature e alla corrosione.

-

Lavorazione chimica: Nella produzione di serbatoi, scambiatori di calore e reattori esposti a sostanze chimiche corrosive.

-

Petrolchimico: Per l'uso in raffinerie, caldaie e sistemi di tubazioni in cui sono fondamentali le alte temperature e la resistenza alla corrosione.

-

Produzione di energia: In turbine a vapore, sistemi di scarico e scambiatori di calore utilizzati nelle centrali elettriche.

-

Marina: Per parti esposte all'acqua di mare e ad altri ambienti corrosivi.

-

Trasformazione alimentare: In apparecchiature di trasformazione alimentare ad alta temperatura che richiedono resistenza all'ossidazione.

Lucidatura a specchio delle barre tonde in acciaio inossidabile 321F

La lucidatura a specchio si riferisce alla finitura superficiale delle barre tonde in acciaio inossidabile, che vengono trattate per ottenere una superficie liscia e lucida. Questo processo non solo migliora l'aspetto estetico del materiale, ma fornisce anche una migliore resistenza alla corrosione. La finitura lucidata a specchio è comunemente utilizzata in applicazioni decorative o dove è richiesta una superficie pulita e igienica, come nelle industrie di trasformazione alimentare e farmaceutica.

Tolleranze: H6, H7, H9, H11, H13

Le tolleranze dimensionali delle barre tonde in acciaio inossidabile ASTM A276 Alloy 321F sono definite da standard specifici che garantiscono che le barre si adattino con precisione alle applicazioni industriali. Queste tolleranze sono classificate per classi di tolleranza:

| Classe di tolleranza | H6 | H7 | H9 | H11 | H13 |

|---|---|---|---|---|---|

| Tolleranza | ±0.020 mm | ±0.030 mm | ±0.050 mm | ±0.080 mm | ±0.100 mm |

| Precisione | Alta | Media | Standard | Larga | Molto larga |

-

Tolleranza H6: Adatta per applicazioni altamente precise, come in componenti che devono essere montati molto strettamente.

-

Tolleranza H7: Tolleranza standard per componenti di media precisione. Comune nelle applicazioni meccaniche e automobilistiche.

-

Tolleranza H9: Tolleranze più ampie, adatte per uso industriale generale.

-

Tolleranze H11 e H13: Queste sono ancora più ampie e spesso applicate dove lievi deviazioni dimensionali non influiscono sulle prestazioni del componente.

La selezione della tolleranza corretta dipende dall'applicazione prevista. Per componenti altamente critici che richiedono un montaggio e prestazioni precisi, le tolleranze H6 o H7 sono ideali. Per usi industriali più generali, H9, H11 o H13 possono essere sufficienti.

Vantaggi della barra tonda in acciaio inossidabile ASTM A276 Alloy 321F

-

Resistenza alle alte temperature: Il materiale funziona bene a temperature fino a 870°C (1600°F), rendendolo ideale per applicazioni ad alta temperatura come l'aerospaziale e i forni industriali.

-

Resistenza alla corrosione: Eccellente resistenza a un'ampia gamma di ambienti corrosivi, in particolare in condizioni di alta temperatura.

-

Saldabilità: La stabilizzazione al titanio consente una saldatura più facile senza il rischio di sensibilizzazione o corrosione intergranulare.

-

Durata: L'elevata resistenza meccanica e la resistenza all'usura garantiscono prestazioni di lunga durata in ambienti difficili.

-

Versatilità: Può essere utilizzato in una varietà di settori tra cui aerospaziale, lavorazione chimica e produzione di energia, rendendolo un materiale altamente versatile.

Conclusione

La barra tonda in acciaio inossidabile ASTM A276 Alloy 321F è un materiale di prim'ordine progettato per applicazioni impegnative in cui la resistenza alle alte temperature e alla corrosione sono fondamentali. Con la sua stabilizzazione al titanio, la finitura lucidata a specchio e le precise classificazioni di tolleranza (H6, H7, H9, H11, H13), offre prestazioni superiori in settori come l'aerospaziale, petrolchimico, navale e della produzione di energia.

![]()

![]()

![]()

![]()