-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

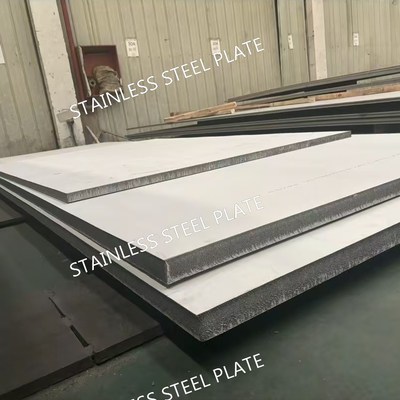

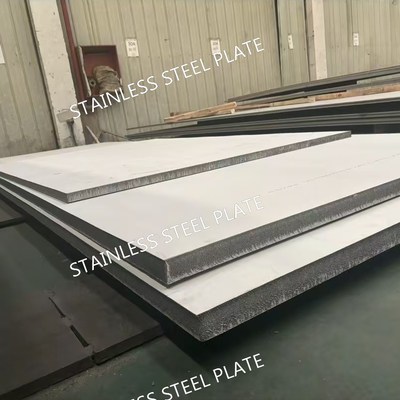

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Fornitore di lastre in acciaio inossidabile 904L - Lastre in lega ad alta resistenza per applicazioni chimiche e marine

| Luogo di origine | Cina |

|---|---|

| Marca | BAOSTEEL TISCO |

| Certificazione | ISO |

| Numero di modello | 904L/N08904 |

| Quantità di ordine minimo | 50 kg |

| Prezzo | 8 - 10 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 20ton a settimana |

| Prodotti | lamiere di acciaio inossidabile | Grado | 904L/N08904 |

|---|---|---|---|

| Spessore | 1,0-80,0 mm | Tecnologia | laminato a freddo, laminato a caldo, forgiato |

| Larghezza | 1000mm 1219mm 1500mm o abitudini come richiesta | Superficie | 2B SEDERE No.1 |

| Standard | BACCANO DELL'EN DI ASTM GB JIS | MOQ | 1 tonnellata |

| Evidenziare | 904l lamiera in acciaio inossidabile,piastre di acciaio legato ad alta resistenza,piastre di acciaio inossidabile di grado marino |

||

Fornitore di lamiere in acciaio inossidabile 904L - Lamiere in lega ad alta resistenza per applicazioni chimiche e marine

Specifiche delle lamiere in acciaio inossidabile

| Nome | Lamiera in acciaio inossidabile 904L |

| Il nostro grado |

Serie 200: 201 202 Serie 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Serie 400: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Acciaio inossidabile Super: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Lega di nichel: C276, C22,G35,Lega X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Tecnica | Laminato a caldo, laminato a freddo, forgiato |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, ecc. |

| Spessore | 0.1 – 80.0mm |

| Gamma di larghezza | 10mm – 2000mm |

| Lunghezza | Personalizzato |

| Finitura | 2B, BA, No.4, 8k, Spazzolato, Hairline, Rivestimento PVD, Sabbiato |

| Servizio | Taglio laser, Piegatura |

| Campione | Disponibile |

Fornitore di lamiere in acciaio inossidabile 904L - Lamiere in lega ad alta resistenza per applicazioni chimiche e marine

La lamiera in acciaio inossidabile 904L è una lega austenitica ad alte prestazioni, rinomata per la sua notevole resistenza alla corrosione, soprattutto in ambienti difficili come impianti di trattamento chimico, applicazioni marine e sistemi industriali ad alta temperatura. Con una composizione accuratamente ottimizzata di nichel, cromo, molibdeno e rame, la 904L è un materiale ideale per applicazioni che richiedono sia resistenza meccanica che resistenza a mezzi aggressivi come acido solforico, acqua di mare e condizioni ricche di cloruri. Questo grado premium di acciaio inossidabile offre non solo una resistenza superiore alla corrosione, ma anche un'eccellente lavorabilità, rendendolo un materiale preferito per fabbricanti e ingegneri in vari settori.

Questa guida completa offre informazioni essenziali sulla lamiera in acciaio inossidabile 904L, dettagliando le sue proprietà, applicazioni e vantaggi, insieme a specifiche tecniche e standard di qualità per aiutare i clienti a prendere decisioni di acquisto informate.

1. Introduzione alla lamiera in acciaio inossidabile 904L

La lamiera in acciaio inossidabile 904L (UNS N08904) è un acciaio inossidabile austenitico non magnetico ad alta lega progettato per l'uso in ambienti corrosivi e ad alta sollecitazione. È particolarmente noto per la sua eccezionale resistenza all'acido solforico e alla corrosione indotta da cloruri. Grazie all'alto contenuto di nichel (circa il 25%), questa lega è più resistente alla tensocorrosione, alla vaiolatura e alla corrosione interstiziale rispetto ad altri gradi di acciaio inossidabile come 304L e 316L. La presenza di rame aumenta ulteriormente la sua resistenza all'acido solforico, il che lo rende il materiale di scelta per applicazioni che richiedono resistenza alla corrosione in ambienti riducenti.

I settori che utilizzano l'acciaio inossidabile 904L includono la lavorazione chimica, il settore marittimo, petrolchimico, farmaceutico e alimentare. Grazie alla sua eccellente resistenza alla corrosione e all'elevata resistenza, è una scelta affidabile per applicazioni come scambiatori di calore, recipienti a pressione, impianti di desalinizzazione e varie altre apparecchiature esposte a condizioni estreme.

2. Caratteristiche principali e vantaggi della lamiera in acciaio inossidabile 904L

Resistenza superiore alla corrosione

-

Resistente agli acidi: Eccellente resistenza all'acido solforico, all'acido fosforico e a molti acidi organici.

-

Corrosione da cloruri: Altamente resistente alla vaiolatura e alla corrosione interstiziale, in particolare in ambienti contenenti cloruri come acqua di mare e salamoia.

-

Resistenza alla tensocorrosione: Capacità superiore di resistere alla tensocorrosione, soprattutto in ambienti contenenti cloruri.

Elevata resistenza meccanica

-

Elevata resistenza alla trazione e allo snervamento.

-

Mantiene la resistenza e la tenacità ad alte temperature e temperature criogeniche.

-

Eccellente formabilità e saldabilità.

Durata a lungo termine

-

Il basso contenuto di carbonio riduce al minimo il rischio di precipitazione di carburi durante la saldatura, garantendo una struttura durevole e resistente alla corrosione.

-

Prestazioni superiori in ambienti estremi, offrendo prestazioni di lunga durata con una manutenzione minima.

Applicazioni versatili

-

Ideale per applicazioni chimiche, marine, alimentari e industriali di fascia alta.

-

In grado di resistere simultaneamente ad ambienti acidi e ricchi di cloruri.

3. Composizione chimica della lamiera in acciaio inossidabile 904L

La lamiera in acciaio inossidabile 904L è composta da una miscela attentamente bilanciata di elementi per garantire la massima resistenza alla corrosione mantenendo al contempo resistenza e stabilità.

| Elemento | Contenuto (%) |

|---|---|

| Carbonio (C) | ≤ 0.020 |

| Cromo (Cr) | 19.0 – 23.0 |

| Nichel (Ni) | 23.0 – 28.0 |

| Molibdeno (Mo) | 4.0 – 5.0 |

| Rame (Cu) | 1.0 – 2.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicio (Si) | ≤ 1.0 |

| Zolfo (S) | ≤ 0.035 |

| Fosforo (P) | ≤ 0.045 |

| Ferro (Fe) | Bilanciamento |

L'alto contenuto di nichel e molibdeno offre una resistenza superiore alla corrosione, in particolare negli acidi riducenti, mentre il rame aumenta le prestazioni della lega in ambienti di acido solforico. Questa miscela rende la 904L una scelta ideale per le industrie che si occupano di sostanze chimiche aggressive.

4. Proprietà meccaniche della lamiera in acciaio inossidabile 904L

Le proprietà meccaniche dell'acciaio inossidabile 904L sono progettate per fornire un eccellente supporto strutturale mantenendo al contempo flessibilità e resistenza alla corrosione.

| Proprietà | Valore |

|---|---|

| Resistenza alla trazione | ≥ 490 MPa |

| Resistenza allo snervamento | ≥ 220 MPa |

| Allungamento | ≥ 35% |

| Durezza (Brinell) | ≤ 200 HB |

| Modulo di elasticità | 200 GPa |

| Densità | 8.0 g/cm³ |

| Intervallo di fusione | 1350–1400°C |

L'elevata resistenza e l'eccellente capacità di allungamento lo rendono adatto ad applicazioni pesanti e garantiscono che possa resistere a condizioni difficili come alta pressione, variazioni di temperatura ed esposizione alla corrosione.

5. Proprietà fisiche della lamiera in acciaio inossidabile 904L

| Proprietà | Valore |

|---|---|

| Conducibilità termica | 12–14 W/m·K |

| Calore specifico | 500 J/kg·K |

| Resistività elettrica | 0.94 μΩ·m |

| Coefficiente di espansione termica | 15 × 10⁻⁶ /°C |

| Proprietà magnetiche | Non magnetico |

La bassa conducibilità termica e le proprietà non magnetiche lo rendono adatto per applicazioni elettriche e termiche in cui stabilità e sicurezza sono fondamentali.

6. Dimensioni e finiture disponibili della lamiera in acciaio inossidabile 904L

Le lamiere in acciaio inossidabile 904L sono disponibili in un'ampia gamma di dimensioni e finiture per soddisfare le varie esigenze dei clienti. Queste lamiere sono disponibili in forme laminate a caldo o laminate a freddo, con le seguenti dimensioni standard:

| Spessore (mm) | Larghezza (mm) | Lunghezza (mm) | Finitura |

|---|---|---|---|

| 0.8 – 6 | 1000–2000 | 2000–6000 | 2B, BA, No.4 |

| 6 – 20 | 1500–2500 | 3000–8000 | No.1, No.4 |

| 20 – 50 | 1500–3000 | 3000–12000 | No.1 |

| > 50 | Personalizzato | Personalizzato | Laminato a caldo |

Le finiture disponibili includono 2B (opaco liscio), BA (ricotto brillante), No.1 (laminato a caldo) e No.4 (spazzolato), con opzioni di finitura personalizzate per applicazioni decorative e specializzate.

7. Applicazioni della lamiera in acciaio inossidabile 904L

La lamiera in acciaio inossidabile 904L viene utilizzata in una varietà di settori in cui sono richieste un'eccezionale resistenza alla corrosione e un'elevata resistenza. Le applicazioni comuni includono:

Industrie chimiche e petrolchimiche

-

Serbatoi e sistemi di tubazioni di acido solforico

-

Scambiatori di calore e reattori per acidi organici

-

Componenti per sistemi di movimentazione dei fluidi in impianti chimici

Marine e offshore

-

Apparecchiature di desalinizzazione dell'acqua di mare

-

Componenti di piattaforme di perforazione offshore

-

Materiali per la costruzione navale per scafi, tubazioni e componenti strutturali esposti all'acqua salata

Lavorazione alimentare e farmaceutica

-

Serbatoi di stoccaggio e recipienti di processo per liquidi alimentari

-

Apparecchiature di processo farmaceutiche per il mantenimento di condizioni sterili

-

Tubazioni e raccordi sanitari per ambienti igienici

Generazione di energia

-

Scambiatori di calore e condensatori negli impianti di produzione di energia

-

Sistemi di desolforazione dei fumi (FGD)

-

Apparecchiature di controllo ambientale che gestiscono gas e liquidi aggressivi

8. Resistenza alla corrosione della lamiera in acciaio inossidabile 904L

L'acciaio inossidabile 904L è specificamente progettato per una resistenza superiore alla corrosione in ambienti chimici aggressivi:

-

Resistenza agli acidi: Funziona bene in ambienti altamente acidi, inclusi acido solforico e fosforico concentrati.

-

Resistenza ai cloruri: Eccellente resistenza alla vaiolatura e alla corrosione interstiziale causata dai cloruri in acqua di mare, salamoie e altri ambienti ricchi di cloruri.

-

Tensocorrosione: Funziona bene sotto stress di trazione, in particolare in condizioni ricche di cloruri.

-

Corrosione intergranulare: Il basso contenuto di carbonio garantisce la prevenzione della precipitazione di carburi durante la saldatura, rendendo la 904L resistente alla corrosione intergranulare.

9. Saldatura e fabbricazione della lamiera in acciaio inossidabile 904L

L'acciaio inossidabile 904L può essere facilmente saldato utilizzando metodi convenzionali come TIG, MIG e SMAW. Non richiede trattamento termico post-saldatura, il che riduce i costi e la complessità della fabbricazione. Tuttavia, per mantenere una resistenza alla corrosione ottimale, si consiglia l'uso di materiali di riempimento e tecniche di saldatura appropriati.

Linee guida per la saldatura:

-

Metodi di saldatura: TIG, MIG e SMAW sono comunemente usati.

-

Materiali di riempimento: Si consigliano bacchette di riempimento 904L o leghe ad alto contenuto di nichel.

-

Trattamento post-saldatura: Generalmente non richiesto, ma in alcuni casi è possibile eseguire la distensione.

10. Imballaggio e spedizione

Le lamiere in acciaio inossidabile 904L sono accuratamente imballate per evitare danni durante il trasporto. L'imballaggio standard include:

-

Pellicola protettiva in plastica

-

Strisce di protezione dei bordi

-

Pallet di legno o casse metalliche

La spedizione internazionale è disponibile, con opzioni per la consegna via aerea, marittima o terrestre a seconda delle esigenze del cliente.

11. Garanzia di qualità e certificazione

Ogni lotto di acciaio inossidabile 904L è sottoposto a rigorosi controlli di qualità e test per garantire che soddisfi i più elevati standard di prestazioni. Le nostre certificazioni includono:

-

Analisi della composizione chimica

-

Test delle proprietà meccaniche

-

Verifica dimensionale

-

Identificazione positiva del materiale (PMI)

-

Conformità agli standard internazionali: ASTM A240, ASTM B625, EN 1.4539, JIS G4304

12. Conclusione

La Lamiera in acciaio inossidabile 904L è un materiale eccezionale per le industrie che richiedono leghe ad alta resistenza e resistenti alla corrosione per ambienti difficili. La sua resistenza superiore alle condizioni acide, ai cloruri e alle alte temperature lo rende la scelta preferita per applicazioni chimiche, marine, farmaceutiche e di trasformazione alimentare. Offrendo durata eccezionale, eccellente formabilità e prestazioni a lungo termine, la 904L è una soluzione affidabile ed economica per le esigenze dei materiali industriali. Contattaci oggi per discutere le specifiche del tuo progetto, i prezzi e le opzioni di consegna.

![]()

![]()

![]()

![]()