-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

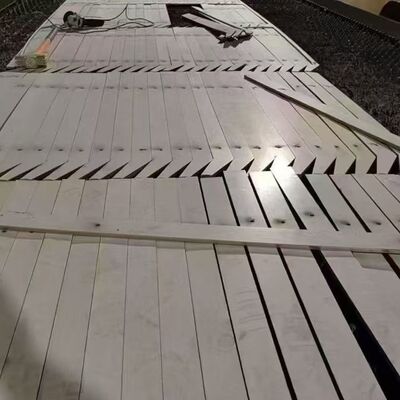

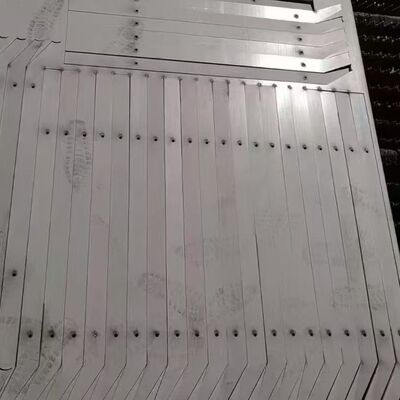

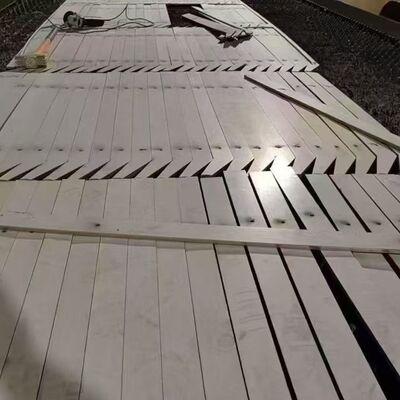

Duplex Stainless Steel Plate S32205 / S31803 / S32750 Laser Cutting Any Size SS Plate

| Herkunftsort | China |

|---|---|

| Markenname | DELTA |

| Zertifizierung | ISO |

| Modellnummer | 2205 2507 |

| Min Bestellmenge | 500 kg |

| Preis | 3200 - 3600 USD/Ton |

| Verpackung Informationen | Holzpaletten + wasserfestes Papier |

| Lieferzeit | 5 - 12 Tage je nach Menge |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 5 Tonnen pro Woche |

Treten Sie mit mir für freie Proben und Kupons in Verbindung.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

x| Produkte | Edelstahlplatte | Grad | 2205 2507 |

|---|---|---|---|

| Standardgröße | 1500*6000mm | Dicke | 2,0 - 40,0 mm |

| Marke | TISCO BAOSTEEL POSCO LISCO | Ladehafen | Hafen von Shanghai |

| Mindestbestellmenge | 500 kg | Verpackung | Holzpaletten + wasserfestes Papier |

| Hervorheben | duplex stainless steel plate S32205,laser cut stainless steel plate,stainless steel plate any size |

||

Duplex Stainless Steel Plate S32205 / S31803 / S32750 Laser Cutting Any Size SS Plate

Products Specification

| Products | Duplex Stainless Steel Plate |

| Thickness | 1.0- 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

High-Performance Duplex Stainless Steel, Cut to Your Exact Requirements

Material Grades Overview

| UNS Number | Common Name | Type | Key Characteristics |

|---|---|---|---|

| S32205 | Duplex 2205 | Standard Duplex | Balanced strength & corrosion resistance; ideal for moderate chloride environments |

| S31803 | Duplex 2205 (older spec) | Standard Duplex | Chemically similar to S32205; often used interchangeably (modern mills typically meet S32205 tighter limits) |

| S32750 | Super Duplex 2507 | Super Duplex | Ultra-high pitting resistance (PREN >40); suited for seawater, sour service, and aggressive chemicals |

Note: While S31803 and S32205 are often grouped together, S32205 has stricter compositional controls (especially nitrogen content) and is preferred for critical applications. All three grades are fully compatible with our laser cutting process.

Why Laser Cut Duplex Stainless Steel?

- ✅ No thermal distortion in thin-to-medium thicknesses

- ✅ Smooth, dross-free edges—often eliminating secondary finishing

- ✅ Complex geometries cut directly from CAD (DXF, DWG, STEP)

- ✅ Material savings through intelligent nesting software

- ✅ Preserved mechanical & corrosion properties due to controlled, localized heat input

Technical Specifications

| Parameter | Details |

|---|---|

| Material Grades | UNS S32205, S31803, S32750 |

| Plate Form | Hot-rolled (mill finish) |

| Thickness Range | 3.0 mm – 40.0 mm |

| Standard Plate Sizes | 2000×6000 mm, 2500×6000 mm (custom blanks available) |

| Cutting Technology | Fiber laser (up to 25 mm), CO₂ laser (25–40 mm) |

| Dimensional Tolerance | ±0.1 mm (≤10 mm), ±0.2 mm (10–25 mm), ±0.5 mm (>25 mm) |

| Edge Quality | ISO 9013 Class 2–3 (smooth, vertical kerf, minimal dross) |

| Surface Options | As-cut, pickled & passivated, beveled edges (for welding) |

| Certifications | EN 10204 3.1/3.2, ASTM A240, NORSOK M-650 (for S32750), full PMI traceability |

Performance Comparison: S32205 vs. S32750

| Property | S32205 / S31803 | S32750 (2507) |

|---|---|---|

| Chromium (Cr) | ~22% | ~25% |

| Molybdenum (Mo) | ~3.0–3.5% | ~3.5–4.0% |

| Nickel (Ni) | ~4.5–6.5% | ~6.0–8.0% |

| Nitrogen (N) | 0.14–0.20% | 0.24–0.32% |

| PREN (Pitting Resistance Equivalent) | 34–38 | 40–45 |

| Yield Strength (min) | 450 MPa | 550 MPa |

| Max Chloride Exposure | Up to ~1,000 ppm | Up to ~5,000+ ppm |

| Typical Use Case | Chemical tanks, pipelines | Subsea manifolds, seawater systems |

PREN = %Cr + 3.3×%Mo + 16×%N — a higher value indicates greater resistance to localized corrosion.

Applications by Industry

- Oil & Gas: Downhole equipment, flowlines, separators, pressure vessels

- Marine & Offshore: Seawater cooling systems, risers, FPSO structural components

- Chemical Processing: Reactors, heat exchangers, acid storage tanks

- Desalination Plants: High-pressure membrane housings, brine heaters

- Power Generation: Flue gas desulfurization (FGD) ducts, scrubber internals

- Pulp & Paper: Bleach plant equipment, digester components

Custom Laser Cutting – No Size Too Big or Small

- Small brackets (50×50 mm)

- Large structural panels (up to 3000×12000 mm with plate joining)

- Intricate perforated patterns, flanges, gaskets, or weld-ready profiles

- Nesting optimization for cost efficiency

- Burr-free edges ready for assembly

- Full documentation (MTRs, PMI reports, dimensional inspection)

Quality Assurance & Compliance

- Positive Material Identification (PMI) via XRF or OES

- Ultrasonic Testing (UT) for plates >20 mm (per ASTM A435/A578)

- Pickling & Passivation to restore optimal surface chromium oxide layer

- Welding procedure support (we recommend qualified procedures to avoid sigma phase formation)