Alle Produkte

-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Superduplex-Edelstahlrohr UNS S32760 SCH40S 6m Länge

| Herkunftsort | China |

|---|---|

| Markenname | DELTA |

| Zertifizierung | ISO |

| Modellnummer | S32760 |

| Min Bestellmenge | 500 kg |

| Preis | 5-10 USD/Kg |

| Verpackung Informationen | Standardverpackung für den Exportieren |

| Lieferzeit | 5 - 12 Tage basierend auf der Menge |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 3 Tonnen pro Woche |

Treten Sie mit mir für freie Proben und Kupons in Verbindung.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

xProduktdetails

| Produkte | Nahtloses rostfreies Stahl | Grad | S32760 |

|---|---|---|---|

| Durchmesser | DN10 - DN400 | Länge | 6 m oder kundenspezifisches Schneiden als Anfrage |

| Standard | ASTM EN | Service | Schneiden |

| Ladeanschluss | Shanghai Hafen | Dicke | 4.0 - 50,0 mm |

| Hervorheben | Super-Duplex-Rohr aus Edelstahl,Rohr UNS S32760 SCH40S,6 m Länge Edelstahlrohr |

||

Produkt-Beschreibung

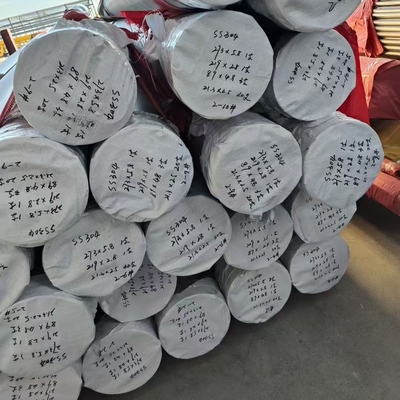

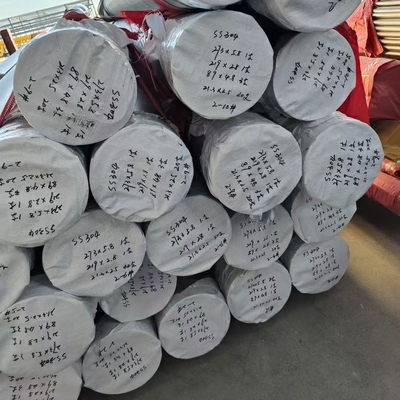

Super-Duplex-Rohr aus Edelstahl UNS S32760 SCH40S Edelstahl Hohlrohrröhren in 6m Länge

Produktspezifikation

| Produktbezeichnung | S2760 Nahtloser Rohr aus Edelstahl |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO und gleichwertige Qualität im GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A312M-94b, u.a. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92. | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994, usw. | |

| Die EU-Richtlinie für die Gewährleistung von Sicherheit und Gesundheitsschutz in der Luft | |

| Größe: | ND5 - DN400 |

| Längen: | 6 m Länge oder auf Wunsch beliebige Länge |

| Anwendungen: | Flüssigkeits- und Gastransport, Struktur, Kessel, Wärmetauscher, Überhitzer |

Übersicht

UNS S32760 Super-Duplex-Edelstahlrohre sind Hochleistungs-Hohlrohre, die für eine außergewöhnliche Festigkeit, Korrosionsbeständigkeit und Haltbarkeit in extremen Umgebungen entwickelt wurden.Kombination der Vorteile austenitischer und ferritischer Edelstahlphasen (normalerweise jeweils 40-60%)Diese Rohre bieten im Vergleich zu Standard-Duplex-Rohren überlegene mechanische Eigenschaften.und bei unterschiedlichen Temperaturen in kritischen Branchen.

Schlüsselparameter

- Legierungsgrad: UNS S32760 (auch bekannt als 2507-Plus oder Zeron® 100, eine Super-Duplexlegierung mit hohem Chrom-, Molybdän- und Stickstoffgehalt).

- Chemische Zusammensetzung (typisch, %):

- Chrom (Cr): 24,0 - 26,0 (erhöht die Oxidations- und allgemeine Korrosionsbeständigkeit).

- Nickel (Ni): 6,0 - 8,0 (stabilisiert die austenitische Phase, verbessert Zähigkeit und Duktilität).

- Molybdän (Mo): 3,0 - 4,0 (erhöht die Beständigkeit gegen Korrosion durch Gruben und Spalten, insbesondere in chloridreichen Umgebungen).

- Stickstoff (N): 0,20 - 0,30 (stärkt die Legierung, erhöht die Schwellwiderstandsfähigkeit und stabilisiert die Duplexstruktur).

- Eisen (Fe): Gleichgewicht.

- Andere Elemente: Kohlenstoff (C) ≤ 0.03, Silizium (Si) ≤ 1.0, Mangan (Mn) ≤ 1.0, Kupfer (Cu) 0,5 - 1.0, Wolfram (W) 0,5 - 1,0 (verbessert die Korrosionsbeständigkeit in rauen Umgebungen).

- Mechanische Eigenschaften:

- Zugfestigkeit: ≥ 800 MPa.

- Ausfallfestigkeit: ≥ 550 MPa (deutlich höher als austenitische Edelstahle wie 316).

- Verlängerung: ≥ 25% (gute Duktilität beim Formen und Schweißen).

- Härte: ≤ 31 HRC.

- Korrosionsbeständigkeit: Ausgezeichnete Korrosionsbeständigkeit (PREN ≥ 40), widerstandsfähig gegen chloridinduzierte Spannungskorrosionscracking (SCC), Korrosionsbeständigkeit durch Korrosion durch Gruben und Spalten.

Normen

UNS S32760 Super-Duplex-Rohre entsprechen strengen internationalen Normen, um Qualität und Konsistenz zu gewährleisten:

- ASTM A790/A790M (Standardspezifikation für nahtlose und geschweißte ferritische/austenitische Duplexrohrröhren).

- ASTM A928/A928M (Standardspezifikation für geschweißtes ferritisches/austenitisches Duplexrohr aus Edelstahl für den allgemeinen Betrieb).

- ASME SA790 (Code für Druckbehälter und Rohrleitungen, weit verbreitet in der Energie- und Chemieindustrie).

- EN 10217-7 (Europäische Norm für geschweißte Rohre aus Edelstahl für Druckzwecke, anwendbar für Super-Duplex-Typ).

Spezifikationen

- Form: Hohles Rohr/Rohr (je nach Anwendungsbedarf in nahtloser oder geschweißter Variante erhältlich).

- Schema: SCH40S (Standardbezeichnung für die Wandstärke von Rohren aus Edelstahl, Ausgleichsfestigkeit und Gewicht für mittlere bis hohe Drucksysteme).

- Längen: 6 m (Standardlänge, auf Anfrage für spezifische Projektbedürfnisse auf kürzere Längen angepasst).

- Außendurchmesser (OD): Normalerweise zwischen 1/2 Zoll (12,7 mm) und 12 Zoll (304,8 mm) (deckt ein breites Spektrum von Anforderungen an industrielle Rohre ab).

- Wandstärke: entspricht den SCH40S-Standards (variiert je nach OD; z.B. 0,154 Zoll für 2-Zoll-OD, 0,216 Zoll für 4-Zoll-OD).

- Oberflächenbearbeitung: Im Allgemeinen eingelegt und passiviert (entfernt Schuppen, verbessert die Korrosionsbeständigkeit und sorgt für eine saubere, einheitliche Oberfläche).

Ähnliche Grade

UNS S32760 gehört zur Super-Duplex-Familie von Edelstahl, mit mehreren vergleichbaren Sorten, die eine hohe Leistung in korrosiven Umgebungen bieten:

- UNS S32750 (2507): Eine weit verbreitete Super-Duplex-Fertigung mit einem etwas geringeren Wolfram- und Kupfergehalt, die ähnliche Korrosionsbeständigkeit und Festigkeit bietet.

- UNS S32550 (Ferralium 255): Kombiniert hohes Chrom-, Molybdän- und Nickelgehalt zur Beständigkeit gegen saure und chloride Umgebungen, mit einer geringfügig geringeren Zugfestigkeit als S32760.

- UNS S32900: Eine Duplexqualität (nicht "Super") mit geringerer Molybdän- und Stickstoffmenge, geeignet für weniger aggressive Umgebungen.

- EN 1.4501: Europäisches Äquivalent zu S32760 mit gleicher chemischer Zusammensetzung und gleicher mechanischer Eigenschaft.

Anwendungen

UNS S32760 Super-Duplex-Rohre sind für die anspruchsvollsten industriellen Umgebungen ausgelegt und daher ideal für:

- Öl- und Gasindustrie: Offshore- und Onshore-Pipelines, Riser und Bohrkopfgeräte, bei denen die Beständigkeit gegen Meerwasser, saures Gas (H2S) und hohen Druck von entscheidender Bedeutung ist.

- Chemische Verarbeitung: Rohrleitungen für den Umgang mit Säuren (z. B. Schwefelsäure, Salzsäure), Chloriden und aggressiven Chemikalien sowie Reaktoren und Wärmetauscher.

- Entsalzungsanlagen: Systeme zur Einnahme von Meerwasser, Umkehrosmose und zum Umgang mit Sole, bei denen die durch Chlorid verursachte Korrosion ein großes Problem darstellt.

- Meerestechnik: Rumpfkomponenten, Ballasttanks und Offshore-Plattformen, die gegen Salzwasserkorrosion und Biofouling beständig sind.

- Stromerzeugung: Systeme zur Entschwefelung von Rauchgasen, Kühlwasserleitungen und Abwasseraufbereitung in fossilen Brennstoffen und Kernkraftwerken.

- Zellstoff- und Papierindustrie: Verdauliche Rohrleitungen und Bleichsysteme, die harten Chemikalien wie Chlordioxid standhalten.

![]()

![]()

![]()

![]()

Empfohlene Produkte