-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

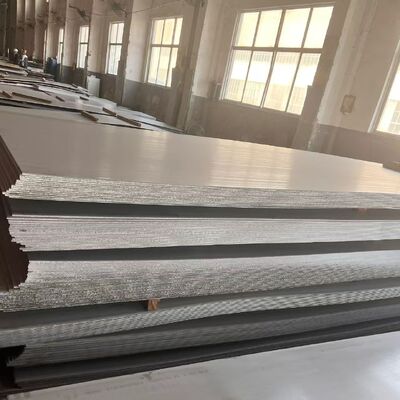

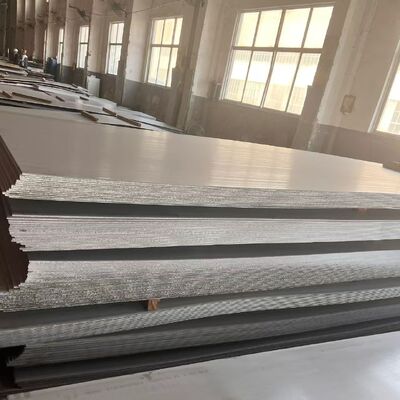

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

2000mm Wide 316L Stainless Steel Plate Cold-Rolled and Hot Rolled Excellent Weldability & Durability

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | DELTA |

| Certification | ISO |

| Numéro de modèle | 316L |

| Quantité de commande min | 500 kg |

| Prix | 3200 - 3600 USD/Ton |

| Détails d'emballage | palettes en bois + papier imperméable |

| Délai de livraison | 5 à 12 jours en fonction de la quantité |

| Conditions de paiement | LC, T/T, Western Union |

| Capacité d'approvisionnement | 5 tonnes par semaine |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Produits | plaque en acier inoxydable | Grade | 316L / 1,4404 |

|---|---|---|---|

| Taille standard | 2000*6000mm | Épaisseur | 2,0 - 40,0 mm |

| Marque | TISCO BAOSTEEL POSCO LISCO | Port de chargement | Port de Shanghai |

| MOQ | 500 kg | Emballage | palettes en bois + papier imperméable |

2000mm Wide 316L Stainless Steel Plate Cold-Rolled and Hot Rolled Excellent Weldability & Durability

Products Specification

| Products | Stainless Steel Plate |

| Thickness | 0.4 - 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

Product Overview

Why 316L? The Low-Carbon Advantage

- Chloride-induced pitting (e.g., seawater, de-icing salts)

- Sulfuric, acetic, and phosphoric acids

- Industrial pollutants and saline atmospheres

Cold-Rolled vs. Hot-Rolled: Choosing the Right Finish

| Feature | Cold-Rolled 316L Plate | Hot-Rolled 316L Plate |

|---|---|---|

| Surface Finish | Smooth, uniform, reflective (typically 2B or BA) | Slightly scaled, matte (often descaled/pickled) |

| Dimensional Tolerance | Tighter tolerances (±0.1 mm on thickness) | Broader tolerances (±0.5 mm or more) |

| Strength | Higher yield strength due to work hardening | Lower strength but greater ductility |

| Applications | Architectural panels, precision tanks, medical equipment, visible surfaces | Structural supports, pressure vessels, shipbuilding, heavy machinery |

| Post-Processing | Ready for polishing or direct use | May require pickling/passivation before service |

| Typical Thickness Range | 0.5 mm – 6 mm | 6 mm – 50+ mm |