Alle producten

-

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

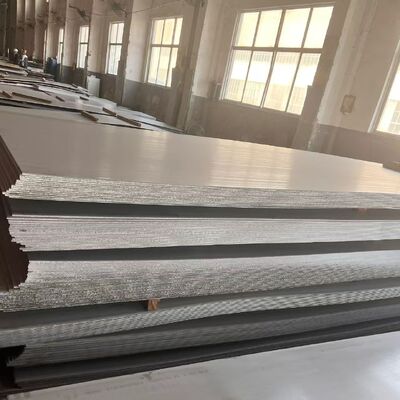

2000mm Wide 316L Stainless Steel Plate Cold-Rolled and Hot Rolled Excellent Weldability & Durability

| Plaats van herkomst | China |

|---|---|

| Merknaam | DELTA |

| Certificering | ISO |

| Modelnummer | 316L |

| Min. bestelaantal | 500 kg |

| Prijs | 3200 - 3600 USD/Ton |

| Verpakking Details | houten pallets + waterdicht papier |

| Levertijd | 5 - 12 dagen op basis van de hoeveelheid |

| Betalingscondities | L/C, T/T, Western Union |

| Levering vermogen | 5Ton per week |

Contacteer me voor vrije steekproeven en coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

xProductdetails

| Producten | roestvrijstalen plaat | Cijfer | 316L / 1.4404 |

|---|---|---|---|

| Standaard maat | 2000*6000mm | Dikte | 2,0 - 40,0 mm |

| Merk | TISCO BAOSTEEL POSCO LISCO | Laadhaven | De haven van Shanghai |

| MOQ | 500 kg | Verpakking | houten pallets + waterdicht papier |

Productomschrijving

2000mm Wide 316L Stainless Steel Plate Cold-Rolled and Hot Rolled Excellent Weldability & Durability

Products Specification

| Products | Stainless Steel Plate |

| Thickness | 0.4 - 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

Product Overview

Engineered for the most demanding industrial environments, our 2000mm wide 316L stainless steel plate is available in both cold-rolled and hot-rolled finishes to meet diverse fabrication needs. Renowned for its exceptional weldability, superior corrosion resistance, and long-term durability, this low-carbon austenitic stainless steel is ideal for applications in marine engineering, chemical processing, pharmaceutical manufacturing, oil & gas, and coastal architecture.

The standardized 2-meter (2000mm) width minimizes seams in large-scale constructions—reducing labor costs, enhancing structural integrity, and accelerating project timelines. Whether you require a smooth, dimensionally precise surface (cold-rolled) or a robust, high-strength base for heavy fabrication (hot-rolled), our 316L plates deliver consistent performance under extreme conditions.

Why 316L? The Low-Carbon Advantage

316L (“L” for low carbon) contains ≤0.03% carbon, significantly reducing the risk of sensitization—a phenomenon where chromium carbides form along grain boundaries during welding or high-temperature exposure. This makes 316L immune to intergranular corrosion in welded structures, eliminating the need for post-weld annealing and ensuring reliability in critical joints.

Its composition includes 2–3% molybdenum, which dramatically enhances resistance to:

- Chloride-induced pitting (e.g., seawater, de-icing salts)

- Sulfuric, acetic, and phosphoric acids

- Industrial pollutants and saline atmospheres

This combination of molybdenum + low carbon sets 316L apart from 304/304L and even standard 316 grades.

Cold-Rolled vs. Hot-Rolled: Choosing the Right Finish

| Feature | Cold-Rolled 316L Plate | Hot-Rolled 316L Plate |

|---|---|---|

| Surface Finish | Smooth, uniform, reflective (typically 2B or BA) | Slightly scaled, matte (often descaled/pickled) |

| Dimensional Tolerance | Tighter tolerances (±0.1 mm on thickness) | Broader tolerances (±0.5 mm or more) |

| Strength | Higher yield strength due to work hardening | Lower strength but greater ductility |

| Applications | Architectural panels, precision tanks, medical equipment, visible surfaces | Structural supports, pressure vessels, shipbuilding, heavy machinery |

| Post-Processing | Ready for polishing or direct use | May require pickling/passivation before service |

| Typical Thickness Range | 0.5 mm – 6 mm | 6 mm – 50+ mm |

Key Benefits

Geadviseerde Producten