-

Bande d'acier inoxydable

-

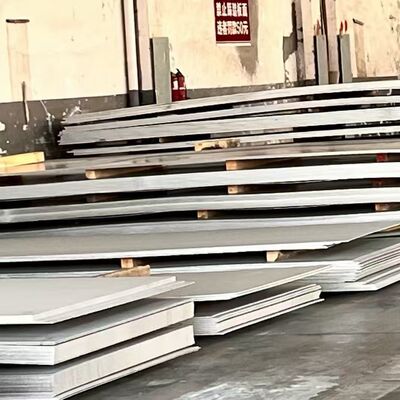

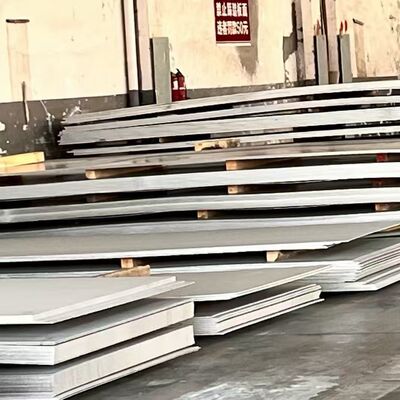

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

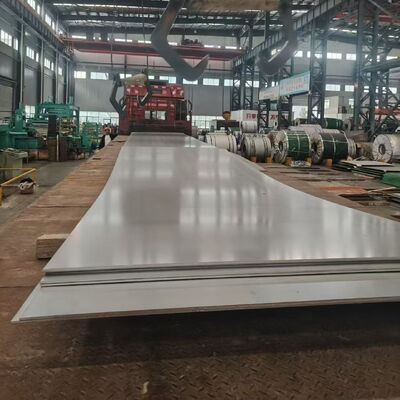

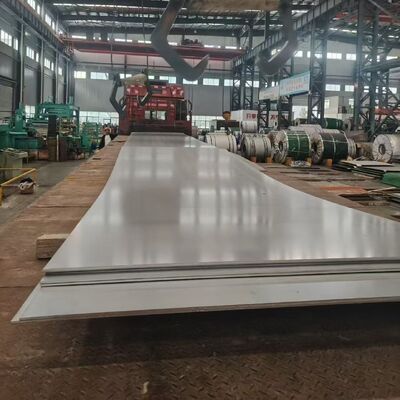

Industrial-Grade 316L Stainless Steel Plate, 2m Wide Ideal for Marine & Chemical Applications

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | DELTA |

| Certification | ISO |

| Numéro de modèle | 316L |

| Quantité de commande min | 500 kg |

| Prix | 3200 - 3600 USD/Ton |

| Détails d'emballage | palettes en bois + papier imperméable |

| Délai de livraison | 5 à 12 jours en fonction de la quantité |

| Conditions de paiement | LC, T/T, Western Union |

| Capacité d'approvisionnement | 5 tonnes par semaine |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Produits | plaque en acier inoxydable | Grade | 316L / 1,4404 |

|---|---|---|---|

| Taille standard | 2000*6000mm | Épaisseur | 2,0 - 40,0 mm |

| Marque | TISCO BAOSTEEL POSCO LISCO | Port de chargement | Port de Shanghai |

| MOQ | 500 kg | Emballage | palettes en bois + papier imperméable |

Industrial-Grade 316L Stainless Steel Plate, 2m Wide Ideal for Marine & Chemical Applications

Products Specification

| Products | Stainless Steel Plate |

| Thickness | 0.4 - 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

Product Overview

Why Choose 316L Over Standard 316?

Key Features & Benefits

- ✅ Exceptional Corrosion Resistance: Resists pitting and crevice corrosion in chloride-rich environments (e.g., seawater, de-icing salts).

- ✅ Weldability: Low carbon content ensures structural integrity post-welding without post-weld annealing.

- ✅ High-Temperature Performance: Maintains strength up to 870°C (1600°F); suitable for intermittent service.

- ✅ Hygienic & Non-Reactive: Meets FDA and USP Class VI standards—ideal for food, beverage, and pharmaceutical equipment.

- ✅ 2-Meter Width Advantage: Reduces fabrication joints, lowers labor costs, and enhances structural continuity in large panels or vessels.

- ✅ Long Service Life: Low maintenance and high durability reduce lifecycle costs in harsh industrial settings.

Typical Applications

| Industry | Application Examples |

|---|---|

| Marine | Ship hulls, propeller shafts, offshore platforms, seawater piping, ballast tanks |

| Chemical Processing | Reactors, distillation columns, acid storage tanks, scrubbers, pump housings |

| Oil & Gas | Subsea pipelines, flare stacks, heat exchangers in refineries |

| Pharmaceutical & Biotech | Sterile tanks, autoclaves, fluid handling systems |

| Water Treatment | Desalination plants, reverse osmosis membranes, brine concentrators |

| Architecture | Coastal building facades, handrails, roofing in high-salt environments |

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grade | ASTM/ASME SA240 316L, UNS S31603, EN 1.4404 |

| Width | 2000 mm (standard); custom widths available upon request |

| Thickness Range | 3 mm to 50 mm (common stock: 6 mm, 10 mm, 12 mm, 20 mm) |

| Length | 6000 mm (standard); cut-to-size options available |

| Surface Finish | 2B (standard), BA, No.4, No.1, or pickled & passivated |

| Carbon (C) | ≤ 0.03% |

| Chromium (Cr) | 16.0–18.0% |

| Nickel (Ni) | 10.0–14.0% |

| Molybdenum (Mo) | 2.0–3.0% |

| Manganese (Mn) | ≤ 2.0% |

| Silicon (Si) | ≤ 0.75% |

| Phosphorus (P) | ≤ 0.045% |

| Sulfur (S) | ≤ 0.030% |

| Density | 8.0 g/cm³ |

| Tensile Strength | ≥ 485 MPa |

| Yield Strength (0.2% offset) | ≥ 170 MPa |

| Elongation | ≥ 40% |

| Melting Point | 1375–1400°C |

| Magnetic Permeability | Generally non-magnetic (may become slightly magnetic after cold working) |

Compliance & Certifications

- Chemical composition analysis

- Mechanical property verification

- Ultrasonic testing (optional for critical applications)

- PMI (Positive Material Identification) certification available

- ASTM A240/A240M

- ASME Section II, Part A

- PED 2014/68/EU (for pressure equipment)

- NORSOK M-001 (for offshore oil & gas)

- ISO 9001:2015 quality management

Fabrication & Machining Guidelines

- Cutting: Plasma, laser, or waterjet cutting recommended. Avoid oxy-fuel due to poor oxidation control.

- Welding: Use matching 316L filler (e.g., ER316L). No preheating required; post-weld cleaning/passivation advised.

- Forming: Excellent ductility allows cold forming. Anneal at 1010–1120°C followed by rapid quenching if severe deformation occurs.

- Machining: Slower speeds and rigid setups reduce work hardening. Use sharp tools and ample coolant.

Storage & Handling Recommendations

- Store in dry, covered areas away from carbon steel dust (to prevent iron contamination).

- Use non-metallic slings or padded lifting equipment to avoid surface scratches.

- Keep plates separated with wooden or plastic spacers to prevent abrasion.

Sustainability & Recyclability

Ordering Information

| Item Code | Description | Stock Availability |

|---|---|---|

| SS316L-2000x6x6000 | 316L Plate, 2000mm W x 6mm T x 6000mm L, 2B Finish | In Stock |

| SS316L-2000x10x6000 | 316L Plate, 2000mm W x 10mm T x 6000mm L, Pickled | In Stock |

| SS316L-2000x20x6000 | 316L Plate, 2000mm W x 20mm T x 6000mm L, No.1 Finish | 2–3 Week Lead Time |

| Custom Orders | Thickness: 3–50mm; Length: up to 12m; Surface: BA/No.4 | Available |

Frequently Asked Questions (FAQ)

A: Yes—its molybdenum content provides excellent resistance to chloride-induced pitting. However, for continuous immersion, consider cathodic protection or higher alloys (e.g., 254 SMO) in stagnant zones.

A: Absolutely. It’s FDA-compliant and commonly used in dairy, brewing, and pharmaceutical systems due to its smooth, non-porous surface.

A: 316L contains 2–3% molybdenum, which 304L lacks. This makes 316L far more resistant to acids, chlorides, and industrial solvents.

A: Yes—we provide precision cutting (±1mm tolerance) via CNC plasma or laser for immediate fabrication readiness.