모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

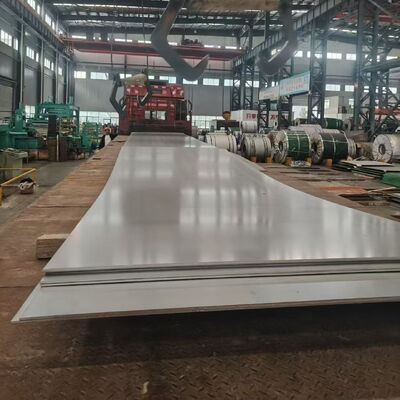

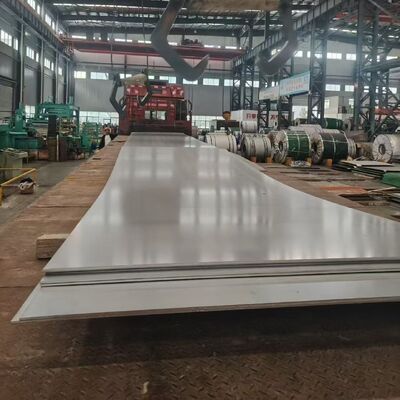

Industrial-Grade 316L Stainless Steel Plate, 2m Wide Ideal for Marine & Chemical Applications

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x제품 상세 정보

| 제품 | 스테인레스 강판 | 등급 | 316L / 1.4404 |

|---|---|---|---|

| 표준 크기 | 2000*6000mm | 두께 | 2.0 - 40.0mm |

| 상표 | 티스코 바오스틸 포스코 리스코 | 선적항 | 상하이항 |

| MOQ | 500kg | 포장 | 나무 팔레트 + 방수 종이 |

제품 설명

Industrial-Grade 316L Stainless Steel Plate, 2m Wide Ideal for Marine & Chemical Applications

Products Specification

| Products | Stainless Steel Plate |

| Thickness | 0.4 - 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

Product Overview

The Industrial-Grade 316L Stainless Steel Plate, with a standard width of 2 meters (2000 mm), is engineered to meet the demanding requirements of marine, chemical processing, pharmaceutical, and offshore industrial environments. As a low-carbon variant of the widely used 316 stainless steel, 316L offers superior corrosion resistance, especially against chlorides and acidic media, making it the material of choice where welding or high-temperature exposure is involved.

This premium-grade plate is manufactured under strict quality control protocols compliant with ASTM A240/A240M, EN 10088-2, and ISO 9001 standards. Its extra-wide format (2m) minimizes the need for seams in large-scale fabrications—ideal for shipbuilding hulls, heat exchangers, desalination units, chemical storage tanks, and architectural cladding in corrosive coastal zones.

Why Choose 316L Over Standard 316?

While both 316 and 316L share nearly identical compositions, 316L contains ≤0.03% carbon, significantly lower than 316’s ≤0.08%. This reduction prevents chromium carbide precipitation during welding, eliminating intergranular corrosion in the heat-affected zone (HAZ). For applications requiring extensive welding or prolonged exposure to aggressive environments (e.g., seawater, sulfuric acid, or salt spray), 316L is the safer, more durable option.

Key Features & Benefits

- ✅ Exceptional Corrosion Resistance: Resists pitting and crevice corrosion in chloride-rich environments (e.g., seawater, de-icing salts).

- ✅ Weldability: Low carbon content ensures structural integrity post-welding without post-weld annealing.

- ✅ High-Temperature Performance: Maintains strength up to 870°C (1600°F); suitable for intermittent service.

- ✅ Hygienic & Non-Reactive: Meets FDA and USP Class VI standards—ideal for food, beverage, and pharmaceutical equipment.

- ✅ 2-Meter Width Advantage: Reduces fabrication joints, lowers labor costs, and enhances structural continuity in large panels or vessels.

- ✅ Long Service Life: Low maintenance and high durability reduce lifecycle costs in harsh industrial settings.

Typical Applications

| Industry | Application Examples |

|---|---|

| Marine | Ship hulls, propeller shafts, offshore platforms, seawater piping, ballast tanks |

| Chemical Processing | Reactors, distillation columns, acid storage tanks, scrubbers, pump housings |

| Oil & Gas | Subsea pipelines, flare stacks, heat exchangers in refineries |

| Pharmaceutical & Biotech | Sterile tanks, autoclaves, fluid handling systems |

| Water Treatment | Desalination plants, reverse osmosis membranes, brine concentrators |

| Architecture | Coastal building facades, handrails, roofing in high-salt environments |

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grade | ASTM/ASME SA240 316L, UNS S31603, EN 1.4404 |

| Width | 2000 mm (standard); custom widths available upon request |

| Thickness Range | 3 mm to 50 mm (common stock: 6 mm, 10 mm, 12 mm, 20 mm) |

| Length | 6000 mm (standard); cut-to-size options available |

| Surface Finish | 2B (standard), BA, No.4, No.1, or pickled & passivated |

| Carbon (C) | ≤ 0.03% |

| Chromium (Cr) | 16.0–18.0% |

| Nickel (Ni) | 10.0–14.0% |

| Molybdenum (Mo) | 2.0–3.0% |

| Manganese (Mn) | ≤ 2.0% |

| Silicon (Si) | ≤ 0.75% |

| Phosphorus (P) | ≤ 0.045% |

| Sulfur (S) | ≤ 0.030% |

| Density | 8.0 g/cm³ |

| Tensile Strength | ≥ 485 MPa |

| Yield Strength (0.2% offset) | ≥ 170 MPa |

| Elongation | ≥ 40% |

| Melting Point | 1375–1400°C |

| Magnetic Permeability | Generally non-magnetic (may become slightly magnetic after cold working) |

Compliance & Certifications

All plates are supplied with full Mill Test Reports (MTRs) per EN 10204 3.1, including:

- Chemical composition analysis

- Mechanical property verification

- Ultrasonic testing (optional for critical applications)

- PMI (Positive Material Identification) certification available

Certified to:

- ASTM A240/A240M

- ASME Section II, Part A

- PED 2014/68/EU (for pressure equipment)

- NORSOK M-001 (for offshore oil & gas)

- ISO 9001:2015 quality management

Fabrication & Machining Guidelines

- Cutting: Plasma, laser, or waterjet cutting recommended. Avoid oxy-fuel due to poor oxidation control.

- Welding: Use matching 316L filler (e.g., ER316L). No preheating required; post-weld cleaning/passivation advised.

- Forming: Excellent ductility allows cold forming. Anneal at 1010–1120°C followed by rapid quenching if severe deformation occurs.

- Machining: Slower speeds and rigid setups reduce work hardening. Use sharp tools and ample coolant.

Storage & Handling Recommendations

- Store in dry, covered areas away from carbon steel dust (to prevent iron contamination).

- Use non-metallic slings or padded lifting equipment to avoid surface scratches.

- Keep plates separated with wooden or plastic spacers to prevent abrasion.

Sustainability & Recyclability

316L stainless steel is 100% recyclable and contains 60–70% recycled content on average. Its long service life and resistance to degradation make it one of the most sustainable materials in heavy industry—reducing replacement frequency and environmental impact over time.

Ordering Information

| Item Code | Description | Stock Availability |

|---|---|---|

| SS316L-2000x6x6000 | 316L Plate, 2000mm W x 6mm T x 6000mm L, 2B Finish | In Stock |

| SS316L-2000x10x6000 | 316L Plate, 2000mm W x 10mm T x 6000mm L, Pickled | In Stock |

| SS316L-2000x20x6000 | 316L Plate, 2000mm W x 20mm T x 6000mm L, No.1 Finish | 2–3 Week Lead Time |

| Custom Orders | Thickness: 3–50mm; Length: up to 12m; Surface: BA/No.4 | Available |

Frequently Asked Questions (FAQ)

Q: Is 316L suitable for seawater immersion?

A: Yes—its molybdenum content provides excellent resistance to chloride-induced pitting. However, for continuous immersion, consider cathodic protection or higher alloys (e.g., 254 SMO) in stagnant zones.

A: Yes—its molybdenum content provides excellent resistance to chloride-induced pitting. However, for continuous immersion, consider cathodic protection or higher alloys (e.g., 254 SMO) in stagnant zones.

Q: Can I use 316L in food processing?

A: Absolutely. It’s FDA-compliant and commonly used in dairy, brewing, and pharmaceutical systems due to its smooth, non-porous surface.

A: Absolutely. It’s FDA-compliant and commonly used in dairy, brewing, and pharmaceutical systems due to its smooth, non-porous surface.

Q: What’s the difference between 316L and 304L?

A: 316L contains 2–3% molybdenum, which 304L lacks. This makes 316L far more resistant to acids, chlorides, and industrial solvents.

A: 316L contains 2–3% molybdenum, which 304L lacks. This makes 316L far more resistant to acids, chlorides, and industrial solvents.

Q: Do you offer cut-to-size services?

A: Yes—we provide precision cutting (±1mm tolerance) via CNC plasma or laser for immediate fabrication readiness.

A: Yes—we provide precision cutting (±1mm tolerance) via CNC plasma or laser for immediate fabrication readiness.

Conclusion

The 2-meter wide Industrial-Grade 316L Stainless Steel Plate delivers unmatched performance in the world’s most corrosive environments. Backed by rigorous certifications, global standards compliance, and optimized for large-scale efficiency, it is the intelligent choice for engineers, fabricators, and procurement specialists seeking reliability, longevity, and cost-effectiveness.

316L stainless steel plate 2m wide, marine grade 316L plate, chemical resistant stainless steel sheet, ASTM A240 316L, 2000mm wide 316L plate, low carbon stainless steel for welding, offshore stainless steel plate, industrial 316L supplier, corrosion resistant metal plate, wide format stainless steel.

추천된 제품