-

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

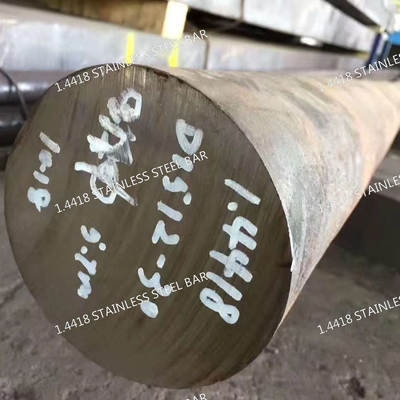

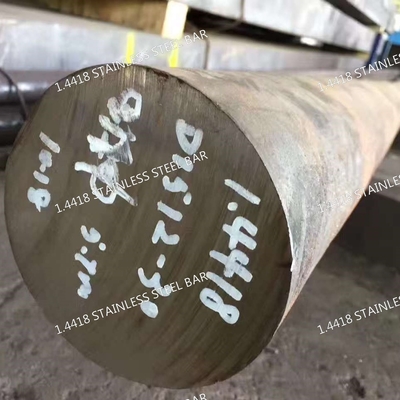

Warmgewalste S41500 roestvrijstalen staaf Precision Cut 1.4418 roestvrijstalen staaf Op maat gemaakte maten

| Plaats van herkomst | China |

|---|---|

| Merknaam | Delta |

| Certificering | ISO 9001 |

| Modelnummer | 1.4418 / S135 / F6NM / 0Cr13Ni5Mo / S41500 |

| Min. bestelaantal | 500 kg |

| Prijs | 2500-3200 USD/Ton |

| Verpakking Details | houten doos of waterdichte papieren omhulsel |

| Levertijd | 5 - 10 dagen |

| Betalingscondities | T/T, Western Union |

| Levering vermogen | 50 ton per maand |

| Naam van de producten | 1.4418 roestvrij staalstaaf | Diameter | 10 - 350mm |

|---|---|---|---|

| Lange | 6 m of op verzoek elke lengte snijden | Oppervlakte | Peperd of helder |

| Service | Snijden | Standaard | ASTM DIN GB EN |

| Andere Producten | ronde balk, vierkante balk, platte balk, enz. | Techniek | Warm gewalst |

| Markeren | Precision Cut S41500 roestvrij staaf,Warmgewalst roestvrij staal S41500,Op maat gemaakt S41500 roestvrij staalstaaf |

||

Warmgewalste S41500 roestvrijstalen staaf Precisie gesneden 1.4418 roestvrijstalen staaf Aangepaste maten beschikbaar

Productspecificatie

| Productnaam | Roestvrijstalen ronde staaf |

| Kwaliteit | 1.4418 / S135 / F6NM / 0Cr13Ni5Mo / S41500 |

| Productdiameterbereik | φ10mm - φ350mm |

| Lengte | 6.1m/stuk of snijden op elke gewenste lengte |

| Oppervlak | Beitsafwerking, heldere afwerking |

| Andere kwaliteit |

304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,C276,600,601,625,718,800,800H,825,926.etc |

| Standaard | ASTM JIS,GB,DIN EN |

| Service | Snijden |

| Andere vorm | Vierkant, plat, zeshoekig, rond.etc |

| Laadpoort | Haven van Shanghai |

| MOQ | 500 kg |

PRODUCTINFORMATIE: 1.4418 ROESTVRIJSTALEN STAaf

1. Materiaalaanduiding

-

EN/DIN Aanduiding: 1.4418

-

Veelvoorkomende namen: Martensitisch precipitatiehardend roestvrij staal.

-

Vergelijkbare normen: Dichtste equivalent aan UNS S17400, AISI 630 (17-4PH), maar met specifieke Europese samenstellingsnuances.

2. Chemische samenstelling (Typisch % Gewicht)

| Element | Min | Max | Typisch |

|---|---|---|---|

| Koolstof (C) | - | 0.07 | 0.04 |

| Chroom (Cr) | 15.0 | 17.5 | 16.5 |

| Nikkel (Ni) | 3.0 | 5.0 | 4.5 |

| Koper (Cu) | 3.0 | 5.0 | 3.5 |

| Niobium (Nb) / Tantaal (Ta) | 0.15 | 0.45 | 0.30 |

| Mangaan (Mn) | - | 1.0 | 0.6 |

| Silicium (Si) | - | 1.0 | 0.4 |

| Fosfor (P) | - | 0.04 | 0.025 |

| Zwavel (S) | - | 0.03 | 0.015 |

| IJzer (Fe) | Balans |

3. Belangrijkste eigenschappen

-

Hoge sterkte & hardheid: Bereikt zeer hoge mechanische eigenschappen door precipitatiehardende warmtebehandeling (H900, H1025, H1150, etc.).

-

Goede corrosiebestendigheid: Superieur aan standaard martensitische kwaliteiten; vergelijkbaar met Type 304 roestvrij staal in veel omgevingen. Weerstand verbetert aanzienlijk na verharding.

-

Goede taaiheid & ductiliteit: Vooral in de oplossingsgegloeide toestand, wat machinale bewerking/vormbaarheid voor de uiteindelijke verharding vergemakkelijkt.

-

Maatvastheid: Behoudt goed vorm en afmetingen tijdens warmtebehandeling.

-

Machinabiliteit: Goed in de oplossingsgegloeide (Conditie A) toestand. Wordt moeilijk na verharding.

4. Mechanische eigenschappen (Na precipitatieharding - Typisch)

| Warmtebehandelingsconditie | Treksterkte (MPa) | Vloeigrens (0,2% Offset) (MPa) | Rek (% in 50 mm) | Hardheid (HRC) |

|---|---|---|---|---|

| H900 | 1310 - 1450 | 1170 - 1310 | 8 - 12 | 40 - 48 |

| H1025 | 1100 - 1240 | 1000 - 1100 | 10 - 14 | 35 - 42 |

| H1150 | 1000 - 1100 | 850 - 950 | 12 - 16 | 30 - 37 |

| Oplossingsgloeien (Conditie A) | ~1000 | ~800 | ~15 | ~32 HRB |

5. Toepassingen (Typisch gebruik voor staven)

-

Zeer sterke assen, assen en bevestigingsmiddelen (bouten, tapeinden)

-

Kleppen en componenten

-

Pompassen en waaiers

-

Onderdelen voor vliegtuigen en ruimtevaart (landingsgestelonderdelen, fittingen)

-

Componenten voor kernreactoren

-

Onderdelen voor de olie- en gasindustrie (downhole tools, kleppen)

-

Tandwielen, spindels en mechanische onderdelen met hoge belasting

6. Beschikbare vormen & maten

-

Vorm: Ronde staven (massief)

-

Diameterbereik: Typisch 5 mm (0,2") tot 250 mm (10") of groter (afhankelijk van de capaciteit van de fabriek).

-

Lengte: Standaard fabrieksmaten (bijv. 3000 mm, 6000 mm) of op maat gesneden.

7. Oppervlakteafwerking (Zoals geleverd - oplossingsgegloeid)

-

Gepeld/gedraaid

-

Geslepen (Precisie)

-

Warmgewalst & gegloeid/gebeitst (voor grotere diameters)

-

Centerloos geslepen (voor nauwe toleranties)

8. Warmtebehandeling

-

Oplossingsgloeien (Conditie A): Typisch 1040°C (1900°F) ±15°C, luchtkoeling of snelle koeling. Geleverd in deze staat.

-

Precipitatieharding: Vereist om de uiteindelijke hoge sterkte te bereiken. Temperatuur/tijd is afhankelijk van de gewenste eigenschappen (bijv. H900: 900°F/482°C gedurende 1 uur, luchtkoeling).

9. Voordelen

-

Uitstekende combinatie van hoge sterkte, goede corrosiebestendigheid en matige taaiheid.

-

Kan in de gegloeide toestand tot complexe vormen worden bewerkt en vervolgens worden verhard met minimale vervorming.

-

Goede lasbaarheid (met bijpassende vulstof en voor-/nabehandeling).

10. Naleving van normen

-

EN 10088-3 (Roestvast staal - Deel 3: Technische leveringsvoorwaarden voor halffabrikaten, staven, staven, draad, profielen en heldere producten van corrosiebestendig staal voor algemene doeleinden)

-

Kan op verzoek worden geleverd volgens andere internationale normen of specificaties van de klant.

11. Verpakking

-

Gebundeld, in kratten of dozen voor bescherming tegen mechanische schade en corrosie tijdens transport/opslag.

![]()

![]()

![]()

![]()