-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

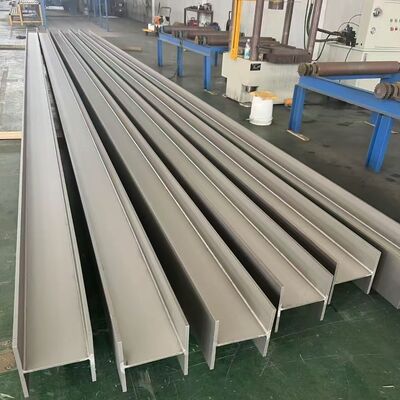

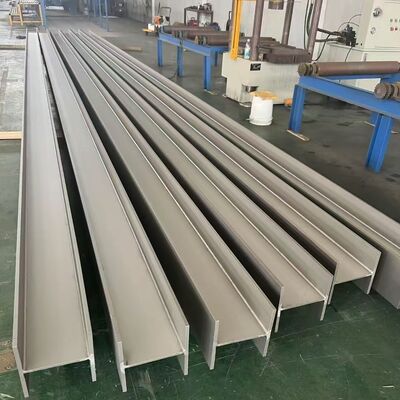

Grado 304 316L 310S Acero inoxidable soldado de h-beam de alta resistencia y resistencia a la corrosión

| Lugar de origen | Porcelana |

|---|---|

| Nombre de la marca | DELTA |

| Certificación | ISO |

| Número de modelo | 304 316L 321 310S |

| Cantidad de orden mínima | 1 tonelada |

| Precio | 2400 - 3500 USD/Ton |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días basado en la cantidad |

| Condiciones de pago | LC, T/T, Western Union |

| Capacidad de la fuente | 5Ton por semana |

| Nombre de los productos | Haz de acero inoxidable de H | TAMAÑO | 100*100 - 400*400m m o aduana como petición |

|---|---|---|---|

| Calificación | Las demás: | Longitud | los 6m o como petición |

| Refinamiento | conserva en vinagre | Otros productos | Ángulo, canal, plano, hexagonal |

| Estándar | EN GB DE ASTM | Tipo | Soldado |

| Resaltar | H-Beam de acero inoxidable 304,Armas de acero soldado 316L,viga de acero estructural resistente a la corrosión |

||

Viga H de acero inoxidable soldado 304 316L 310S de grado, acero estructural de alta resistencia y resistente a la corrosión

Especificaciones del producto

| Nombre del producto | Viga H de acero inoxidable | |||

| Espesor | 6.0~40.0mm | |||

| Longitud | 6 m/pieza o corte a medida según solicitud | |||

| Superficie | NO.1 | |||

| Tecnología | Soldado / Laminado en caliente | |||

| Grado de acero | 304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202,409,410,420,430. | |||

| Estándar | ASTM EN GB JIS DIN | |||

| Prueba | Prueba de tracción, prueba de fluencia, elongación, prueba de flexión en frío, dureza, prueba de corrosión cristalina, prueba de composición química. | |||

| Embalaje | Papel impermeable y marco de madera | |||

| MOQ | 1 tonelada | |||

| Mecanizado | Corte, Taladrado | |||

Viga H de acero inoxidable soldado Grado 304 / 316L / 310S – Acero estructural de alta resistencia y resistente a la corrosión

Descripción general del producto

Las vigas H de acero inoxidable soldado son componentes estructurales esenciales ampliamente utilizados en la construcción moderna, estructuras industriales, ingeniería marina, plantas químicas y aplicaciones de alta temperatura. Entre los grados más populares se encuentran AISI 304, 316L y 310S, cada uno de los cuales ofrece distintas ventajas en términos de resistencia mecánica, resistencia a la corrosión y estabilidad térmica. Estas vigas H se fabrican utilizando procesos avanzados de soldadura por arco sumergido (SAW) o soldadura de alta frecuencia (HFW), lo que garantiza una precisión dimensional precisa, una integridad de soldadura constante y el cumplimiento de normas internacionales como GB/T 33814-2017, ASTM A276 y EN 10088.

Nuestras vigas H de acero inoxidable soldado combinan una capacidad de carga superior con una durabilidad excepcional en entornos agresivos, lo que las hace ideales tanto para la estética arquitectónica como para el exigente rendimiento de la ingeniería.

Características y beneficios clave

- Relación resistencia-peso alta: la geometría de la sección transversal optimizada ofrece una mayor capacidad de carga con un menor uso de material.

- Excelente resistencia a la corrosión: especialmente en entornos ricos en cloruro (316L) o de alta temperatura oxidativa (310S).

- Dimensiones personalizables: disponible en una amplia gama de anchos de ala, alturas de alma y espesores para cumplir con los requisitos específicos del proyecto.

- Fabricación de precisión: las líneas de producción totalmente automatizadas garantizan tolerancias ajustadas y una calidad uniforme.

- Ecológico y reciclable: el acero inoxidable es 100% reciclable, lo que apoya las prácticas de construcción sostenible.

- Bajo mantenimiento: resiste la oxidación, las manchas y la degradación, lo que reduce significativamente los costos del ciclo de vida.

Comparación de grados de materiales

| Propiedad | Grado 304 | Grado 316L | Grado 310S |

|---|---|---|---|

| Número UNS | S30400 | S31603 | S31008 |

| Composición (típica) | 18% Cr, 8% Ni | 16–18% Cr, 10–14% Ni, 2–3% Mo | 24–26% Cr, 19–22% Ni |

| Resistencia a la corrosión | Buena en atmósferas suaves | Excelente en entornos marinos y ácidos | Sobresaliente en oxidación y alta temperatura |

| Temperatura máx. de servicio | ~870°C (intermitente) | ~800°C | 1150°C continuo, hasta 1200°C |

| Soldabilidad | Excelente | Excelente (bajo carbono = sin sensibilización) | Buena (requiere entrada de calor controlada) |

| Aplicaciones comunes | Arquitectura, procesamiento de alimentos, tanques | Plantas químicas, plataformas offshore | Hornos, hornos, sistemas de escape |

| Densidad (g/cm³) | 7.93 | 7.98 | 7.98 |

Especificaciones técnicas

Nuestras vigas H soldadas se producen según los siguientes parámetros:

-

Cumplimiento de normas:

- GB/T 33814-2017 (China)

- ASTM A276 / A484 (EE. UU.)

- EN 10088-3 (Europa)

- ISO 15510

-

Proceso de fabricación:

- Corte de precisión de placas de acero inoxidable

- Ensamblaje automático (alma + alas)

- Soldadura por arco sumergido o soldadura de alta frecuencia

- Tratamiento térmico posterior a la soldadura (si es necesario)

- Corrección dimensional y enderezamiento

- Acabado superficial (decapado, pasivación o pulido)

- Inspección ultrasónica y de rayos X de soldaduras (opcional)

-

Tolerancias dimensionales (según GB/T 33814):

- Altura (H): ±2,0 mm

- Ancho de ala (B): ±2,0 mm

- Espesor del alma (tw): ±0,5 mm

- Espesor del ala (tf): ±0,5 mm

- Rectitud: ≤1,5 mm/m

-

Tamaños disponibles (tamaños personalizados bajo pedido):

- Altura: 100 mm – 1000 mm

- Ancho de ala: 50 mm – 500 mm

- Espesor: 4 mm – 30 mm

- Longitud estándar: 6 m, 9 m, 12 m (servicio de corte a medida disponible)

Propiedades mecánicas (valores típicos)

| Grado | Límite elástico (MPa) | Resistencia a la tracción (MPa) | Alargamiento (%) | Dureza (HV) |

|---|---|---|---|---|

| 304 | ≥205 | ≥515 | ≥40 | ≤200 |

| 316L | ≥170 | ≥485 | ≥40 | ≤200 |

| 310S | ≥205 | ≥520 | ≥40 | ≤200 |

Los valores pueden variar ligeramente según las condiciones de trabajo en frío o tratamiento térmico.

Aplicaciones por industria

-

Construcción y arquitectura:

Rascacielos, puentes, fachadas, marcos resistentes a los terremotos, donde la estética y la longevidad son importantes. -

Química y petroquímica:

Soportes de reactores, bastidores de tuberías y estructuras de plataformas expuestas a ácidos, disolventes o rocío salino (316L preferido). -

Marina y offshore:

Estructuras de muelles, componentes de construcción naval y marcos de soporte submarinos que requieren resistencia a los cloruros. -

Energía y potencia:

Soportes de calderas, carcasas de turbinas y conductos de gases de combustión en centrales eléctricas (310S destaca en zonas de alta temperatura). -

Alimentos y farmacéutica:

Estructuras estructurales higiénicas que deben cumplir estrictos estándares de limpieza y no contaminación (304/316L).

¿Por qué elegir vigas H soldadas en lugar de laminadas en caliente?

- Flexibilidad de diseño: las vigas soldadas se pueden fabricar en tamaños no estándar que no están disponibles en los catálogos laminados en caliente.

- Eficiencia de material: las secciones transversales a medida reducen el peso sin comprometer la resistencia, lo que ahorra hasta un 15% en el uso de acero.

- Acabado superficial superior: sin cascarilla de laminación; superficies más lisas ideales para la exposición arquitectónica o la adhesión del revestimiento.

- Calidad constante: la soldadura automatizada garantiza una microestructura uniforme y una tensión residual mínima.

Garantía de calidad y pruebas

Cada lote se somete a un riguroso control de calidad:

- Análisis químico (espectrometría)

- Pruebas de tracción y flexión

- Pruebas no destructivas (NDT): UT, RT o PT para soldaduras críticas

- Pruebas de corrosión: pulverización salina (ASTM B117), resistencia a la picadura (cálculo PREN)

- Inspección dimensional: escaneo láser para la precisión del perfil

Certificados proporcionados: Informe de prueba del molino (MTR), cumplimiento de EN 10204 3.1, RoHS/REACH (bajo pedido).

Información para pedidos

Para realizar un pedido o solicitar una cotización, especifique:

- Grado (304 / 316L / 310S)

- Dimensiones (H × B × tw × tf)

- Longitud y cantidad

- Acabado superficial (por ejemplo, 2B, BA, No.4, decapado)

- Requisitos adicionales (por ejemplo, NDT, certificación, embalaje)

Ofrecemos envío global, entrega justo a tiempo y soporte de ingeniería para proyectos complejos.

Conclusión

Las vigas H de acero inoxidable soldado de grado 304, 316L y 310S representan el pináculo del acero estructural moderno, fusionando resistencia, resistencia a la corrosión y versatilidad de diseño. Ya sea que esté construyendo un centro turístico costero, una refinería química o un horno industrial de alta temperatura, nuestras vigas H ofrecen un rendimiento y un valor inigualables durante décadas de vida útil. Respaldadas por estrictos controles de calidad y fabricación personalizable, son la opción inteligente para ingenieros y arquitectos que se niegan a comprometerse.

![]()

![]()

![]()

![]()