-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

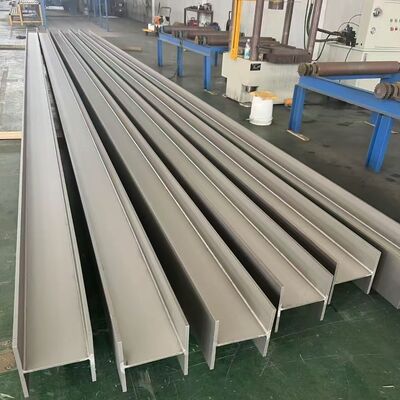

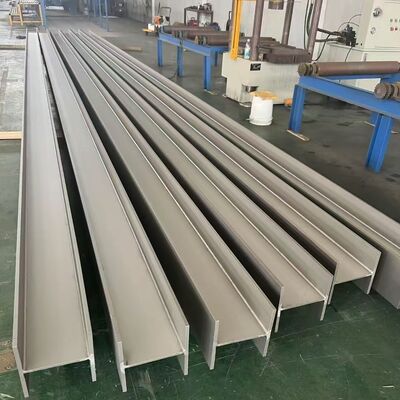

グレード304 316L 310S 溶接ステンレス鋼 H形鋼 高強度 & 耐腐食性 構造用鋼

| 製品名 | ステンレス鋼Hのビーム | サイズ | 100*100 -要求として400*400mmまたは習慣 |

|---|---|---|---|

| 学年 | 304 316L 321 310Sなど | 長さ | 要求として6mまたは |

| 仕上げ | ピクルスにすること | 他の製品 | 角度、六角形チャネル、平ら |

| 標準 | ASTM EN GB | タイプ | 溶接 |

| ハイライト | 304 ステンレス 鋼のHビーム,316L 溶接鋼ビーム,耐食性構造用鋼ビーム |

||

グレード 304 316L 310S 溶接式ステンレス鋼 Hビーム 高強度・耐腐蝕性構造鋼

製品仕様

| 製品名 | ステンレス鋼のHビーム | |||

| 厚さ | 6.0~40.0mm | |||

| 長さ | 6m/pcs または要求に応じてカスタム長さに切る | |||

| 表面 | 違う1 | |||

| テクノロジー | 溶接/熱巻き | |||

| 鉄鋼類 | 304304L,309S,310S316,316Ti317317L321,347,347H,304N,316L, 316N201,202,409,410,420,430. | |||

| スタンダード | ASTM EN GB JIS DIN | |||

| テスト | 張力試験,出力試験,伸縮試験,冷たい屈曲試験,硬さ,結晶腐食試験,化学組成試験 | |||

| 梱包 | 防水紙と木製の枠 | |||

| MOQ | 1トン | |||

| 機械加工 | 切る,掘る | |||

グレード 304 / 316L / 310S 溶接式ステンレス鋼Hビーム 高強度・耐腐蝕構造鋼

製品概要

溶接したステンレス鋼のHビームは,現代の建築,産業用フレームワーク,船舶工学,化学工場,高温アプリケーションで広く使用される不可欠な構造部品です.AISI 304 は 最も 人気 な グレード の 一つ です316Lと310Sは,それぞれ,機械的強度,耐腐蝕性,熱安定性において明確な利点を提供しています.これらのHビームは,高度な自動潜水弧溶接 (SAW) または高周波溶接 (HFW) プロセスを用いて製造されています.精密な寸法精度,一貫した溶接の整合性,およびGB/T 33814-2017,ASTM A276,EN 10088などの国際規格の遵守を保証する.

Our welded stainless steel H-beams combine superior load-bearing capacity with exceptional durability in aggressive environments—making them ideal for both architectural aesthetics and demanding engineering performance.

主要 な 特徴 と 利点

- 高強度/重量比:最適化された横切りの幾何学により,より少ない材料使用でより大きな負荷能力を提供します.

- 優れた耐腐食性:特に塩化物 (316L) の多い環境や高温酸化 (310S) の環境において.

- カスタマイズ可能な寸法: プロジェクト特有の要件を満たすために,幅広いフレンズ幅,ウェブの高さ,厚さで利用できます.

- 精密製造: 完全に自動化された生産ラインは,厳格な許容量と均一な品質を保証します.

- 環境に優しい&リサイクル可能:ステンレス鋼は100%リサイクル可能で,持続可能な建築法を支持します.

- 低保守性: 腐食,染色,劣化に耐性があり,ライフサイクルコストを大幅に削減します.

材料 の 品質 を 比較 する

| プロパティ | グレード304 | グレード316L | グレード310S |

|---|---|---|---|

| UNS番号 | S30400 | S31603 | S31008 |

| 構成 (典型) | 18% Cr,8% Ni | 16~18% Cr,10~14% Ni,2~3% Mo | 24~26% Cr,19~22% Ni |

| 耐腐食性 | 温かい環境では良い | 海洋や酸性環境では 優れています | 酸化と高温で優れた |

| 最大サービス温度 | ~870°C (間歇性) | ~800°C | 連続1150°C,最大1200°C |

| 溶接可能性 | すごい | 優れた (低炭素 = 感受性がない) | 良い (制御された熱入力が必要) |

| 一般的な用途 | 建築,食品加工,タンク | 化学工場,オフショアプラットフォーム | オーブン,オーブン,排気装置 |

| 密度 (g/cm3) | 7.93 | 7.98 | 7.98 |

テクニカル仕様

溶接したHビームは,次のパラメータで生産されます:

-

基準の遵守:

- GB/T 33814-2017 (中国)

- ASTM A276 / A484 (アメリカ)

- EN 10088-3 (ヨーロッパ)

- ISO15510

-

製造プロセス:

- 鋼鉄板の切断精度

- 自動組立 (網+フレンズ)

- 潜水弧溶接または高周波溶接

- 溶接後熱処理 (必要に応じて)

- 寸法修正と直直

- 表面加工 (ピッキング,パシブ化,磨き)

- 超音波とX線による溶接検査 (オプション)

-

寸法許容量 (GB/T 33814 単位で):

- 高さ (H): ±2.0 mm

- フレンズ幅 (B): ±2.0 mm

- 網の厚さ (tw): ±0.5mm

- フレンズの厚さ (tf): ±0.5 mm

- 直さ: ≤1.5 mm/m

-

使用可能なサイズ (要求に応じてカスタムサイズ):

- 高さ: 100mm 1000mm

- フレンズの幅: 50 mm ¥ 500 mm

- 厚さ: 4mm 30mm

- 標準長さ: 6m, 9m, 12m (長さに切るサービス利用可能)

メカニカルプロパティ (典型的な値)

| グラード | 性能強度 (MPa) | 張力強度 (MPa) | 伸縮 (%) | 硬さ (HV) |

|---|---|---|---|---|

| 304 | ≥205 | ≥515 | ≥40 | ≤200 |

| 316L | ≥170 | ≥485 | ≥40 | ≤200 |

| 310S | ≥205 | ≥520 | ≥40 | ≤200 |

値が冷却処理や熱処理条件によってわずかに異なる場合がある.

産業による応用

-

建築と建築:

摩天楼,橋,玄関,耐震のフレーム 美しいものや長寿が重要な場所 -

化学・石油化学

原子炉の支柱,パイプラック,およびプラットフォーム構造は,酸や溶媒,または塩噴霧にさらされている (316Lが好ましい). -

海洋とオフショア

ドック構造,造船部品,水下支架は 塩化物耐性が必要です -

エネルギーと電力:

発電所のボイラー支柱,タービンハウジング,煙突ガス管 (310Sは高温地帯で優れている). -

食品・医薬品

厳格な清潔性と汚染防止基準 (304/316L) に準拠する衛生的な構造の枠組み.

熱く 巻き た H ビーム を 選ぶ の は なぜ です か

- 設計の柔軟性: 熱巻きカタログで入手できない非標準サイズで溶接梁を製造することができます.

- 材料の効率性: 材質に合わせた横断面は強さを損なうことなく重量を削減し,鋼材の使用量を最大15%削減します.

- 優れた表面仕上げ: 磨き場のスケールがない. 建築的な露出やコーティング粘着のために理想的な滑らかな表面.

- 一貫した品質:自動溶接は,均一な微細構造と最小限の残留ストレスを保証します.

品質保証と試験

すべてのバッチは厳格な品質管理を受けます

- 化学分析 (スペクトロメトリ)

- 張力・屈曲試験

- 非破壊性試験 (NDT): 重要な溶接物に対して UT,RT,または PT

- 腐食試験:塩噴霧 (ASTM B117) 孔穴耐性 (PREN計算)

- 寸法検査:プロファイルの精度のためにレーザースキャン

提供された証明書:ミール試験報告 (MTR),EN 10204 3.1RoHS/REACH準拠 (要求に応じて)

注文情報

注文またはオプションを依頼するには,以下を指定してください.

- グレード (304 / 316L / 310S)

- 尺寸 (H × B × tw × tf)

- 長さと量

- 表面仕上げ (例えば,2B,BA,No.4漬け)

- 追加要件 (例えば,NDT,認証,包装)

複雑なプロジェクトに グローバル配送や 間に合う配達 エンジニアリングのサポートを提供しています

結論

304,316L,および310S級の溶接式不?? 鋼Hビームは,現代の構造鋼の融合強度,耐腐蝕性,および設計の多様性の頂点を表しています.海岸リゾートを作ろうとしているか化学精製工場や高温工業炉でも Hビームは 数十年に渡る使用寿命で 卓越した性能と価値を提供します厳格な品質管理と 調整可能な製造によって裏付けられています妥協を拒むエンジニアや建築家にとって 賢明な選択です

![]()

![]()

![]()

![]()