Todos los productos

-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

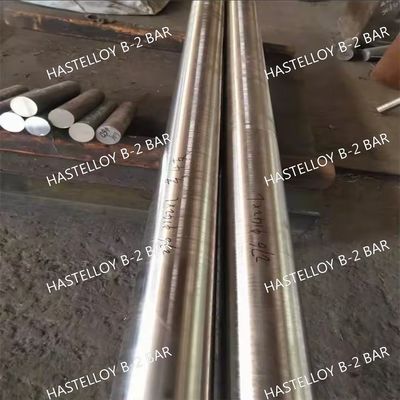

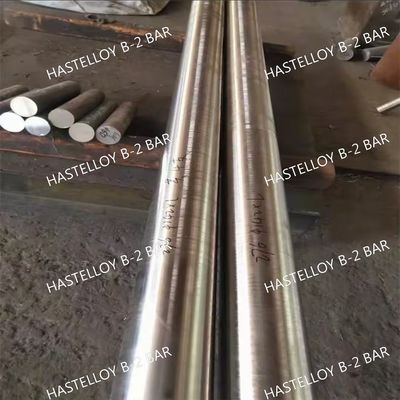

ASTM Standard Hastelloy B-2 Round Bar High Purity Nickel Alloy Round Rods Custom Lengths

| Lugar de origen | PORCELANA |

|---|---|

| Nombre de la marca | DELTA |

| Certificación | ISO |

| Número de modelo | Hastelloy B-2 |

| Cantidad de orden mínima | 10 kg |

| Precio | 30 - 50 USD/Kg |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días basado en la cantidad |

| Condiciones de pago | L/C, T/T, Western Union |

| Capacidad de la fuente | 3 toneladas por semana |

Datos del producto

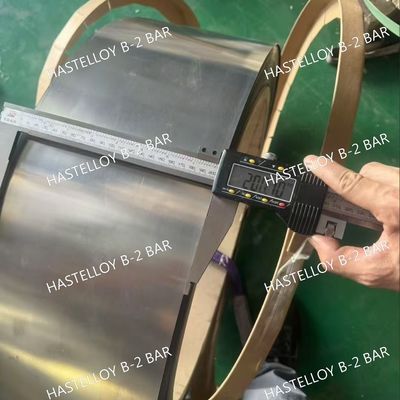

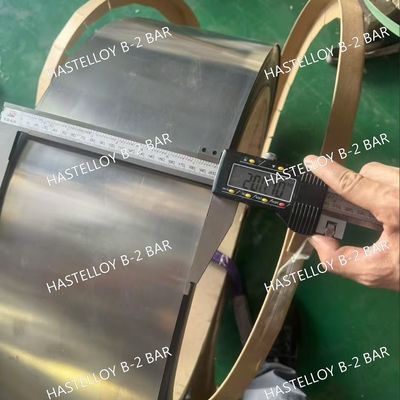

| Productos | Barra redonda Hastelloy B-2 | Calificación | Hastelloy B-2 |

|---|---|---|---|

| Diámetro | 10 - 350m m | Longitud | corte personalizado de cualquier longitud a petición |

| Estándar | ASTM EN | Servicio | CORTE |

| Puerto de carga | Puerto de Shanghai | Superficie | brillante, negro |

| Resaltar | ASTM Standard Hastelloy B-2 round bar,high purity nickel alloy rods,custom length nickel alloy round bars |

||

Descripción de producto

ASTM Standard Hastelloy B-2 Round Bar High Purity Nickel Alloy Round Rods Custom Lengths

More Specification Informations

| Products Name | Hastelloy B-2 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

ASTM Standard Hastelloy B-2 Round Bar High Purity Nickel Alloy Round Rods Custom Lengths

1. Product Introduction

Hastelloy B-2 round bar, designated as UNS N10665 and Werkstoff Nr. 2.4617, is a premium high-purity nickel-molybdenum (Ni-Mo) alloy rod engineered to excel in the most aggressive reducing environments. Developed by Haynes International in the 1960s, this alloy achieves exceptional corrosion resistance and thermal stability through stringent control of impurity elements—with carbon and silicon contents both limited below 0.01%—and a molybdenum concentration of 26-30% that forms the core of its anti-corrosion capability.

What distinguishes our Hastelloy B-2 round bars is their compliance with strict ASTM standards and fully customizable lengths, tailored to eliminate material waste in equipment fabrication. The high-purity composition minimizes intergranular precipitation, avoiding the brittleness issues common in lesser alloys when exposed to elevated temperatures. This makes the rods ideal for critical components where structural integrity and corrosion resistance are non-negotiable, spanning industries from chemical processing to nuclear engineering.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Chemical Composition (Max/Range, %) | Nickel (Ni): Bal., Molybdenum (Mo): 26.0-30.0, Iron (Fe): ≤2.00, Chromium (Cr): ≤1.00, Cobalt (Co): ≤1.00, Carbon (C): ≤0.02, Manganese (Mn): ≤1.00, Silicon (Si): ≤0.10, Phosphorus (P): ≤0.040, Sulfur (S): ≤0.030 |

| Diameter Range | 5 mm - 500 mm (Precision tolerance options: H8-H13, K9-K12 or custom) |

| Length | 100 mm - 3000 mm standard; Custom lengths available on request |

| Surface Finish | Black, bright polished, rough turned, No.4 finish, matt finish, BA finish |

| Mechanical Properties (Room Temperature) | - Tensile Strength: ≥760 MPa (110,000 psi)

|

| Physical Properties | - Density: 9.2 g/cm³

|

| Temperature Limitation | Avoid service between 538°C-871°C (1000°F-1600°F) to prevent phase precipitation |

3. Compliance Standards

Our Hastelloy B-2 round bars adhere to globally recognized standards, ensuring consistency and compatibility with international engineering requirements:

- ASTM B335 / ASME SB335: Primary standard for nickel-alloy rod and bar, governing chemical composition, mechanical properties, and dimensional tolerances. Bars with diameter ≥3.5 inches also comply with ASTM B564/ASME SB564 for forgings .

- UNS N10665: Unified Numbering System designation for global material identification .

- Werkstoff Nr. 2.4617: German material number for compliance with European engineering specifications .

- ISO 15848-1: Certified for sealing performance in critical applications like nuclear fuel processing .

4. Similar Grades

While Hastelloy B-2 is unparalleled in reducing environments, these alternatives address specific application needs:

- Hastelloy B-3 (UNS N10675): Enhanced version with optimized silicon and iron levels, improving weldability and resistance to intergranular corrosion. Preferred for welded structures in high-temperature reducing environments .

- Hastelloy B-4 (UNS N10629): Features lower carbon and silicon content than B-2, delivering superior thermal stability and resistance to stress corrosion cracking (SCC) in fluctuating temperature conditions.

- Alloy 600 (UNS N06600): Nickel-chromium alloy with excellent oxidation resistance but lower molybdenum content—suitable for milder reducing environments where cost efficiency is prioritized.

5. Industrial Applications

The unique properties of Hastelloy B-2 round bars make them indispensable in harsh-service industries, with proven performance in:

- Chemical Processing: Manufacture of hydrochloric acid recovery systems (PVC production) and sulfuric acid ,where service life exceeds 15 years—5-8 times longer than stainless steel .

- Nuclear Engineering: Pump and valve components for high-level radioactive waste treatment, with annual corrosion rates below 0.01mm in plutonium nitrate solutions .

- Environmental Technology: Wet flue gas desulfurization (FGD) systems, tolerating chloride concentrations up to 50,000 ppm and extending maintenance cycles from 6 months to 3+ years .

- Pharmaceuticals: Hydrogenation reactor internals, resisting corrosion from bromide-containing acetic acid at 120°C while maintaining product purity .

- Petrochemicals: Catalyst regeneration equipment handling hot, chloride-rich hydrocarbons without stress corrosion failure .

6. Other Related Products

Complementing our round bars, we offer a full range of Hastelloy B-2 products for integrated system fabrication:

- Plates & Sheets: ASTM B333/ASME SB333 compliant, available in 1mm-100mm thickness for pressure vessel and reactor shells .

- Pipes & Tubes: Seamless (ASTM B622) and welded (ASTM B619) options, with OD 6mm-600mm for corrosive fluid transfer .

- Forgings: Custom-shaped components (valve bodies, pump impellers) per ASTM B564, optimized for high-pressure applications .

- Welding Consumables: Matching electrodes and wires to ensure weld joints with equivalent corrosion resistance and mechanical strength.

![]()

![]()

![]()

![]()

Productos recomendados