-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

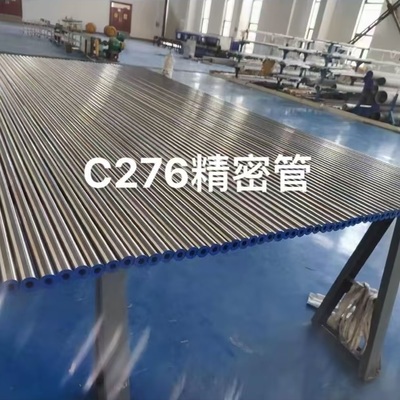

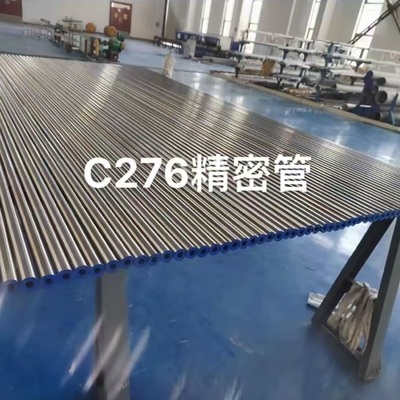

Hastelloy C276 Precision Tubing Polished Surface High Temperature Resistance for Oil & Gas/Pharmaceutical Use

| Lugar de origen | PORCELANA |

|---|---|

| Nombre de la marca | DELTA |

| Certificación | ISO |

| Número de modelo | Hastelloy C276 |

| Cantidad de orden mínima | 10 kg |

| Precio | 40 - 50 USD/Kg |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días basado en la cantidad |

| Condiciones de pago | L/C, T/T, Western Union |

| Capacidad de la fuente | 3 toneladas por semana |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Productos | Hastelloy C276 tuberías | Calificación | Hastelloy C276 |

|---|---|---|---|

| Diámetro | 6 - 219 mm | Longitud | corte personalizado de cualquier longitud a petición |

| Estándar | ASTM EN | Servicio | Corte |

| Puerto de carga | Puerto de Shanghai | Superficie | Brillante |

| Resaltar | Hastelloy C276 precision tubing,Polished nickel alloy tubing,High temperature resistant tubing |

||

Hastelloy C276 Precision Tubing Polished Surface High Temperature Resistance for Oil & Gas/Pharmaceutical Use

More Specification Informations

| Products Name | Hastelloy C276 pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy C276 Precision Tubing: Polished Surface & High-Temperature Resistance for Oil & Gas and Pharmaceutical Applications

Introduction

Hastelloy C276 precision tubing is a premier nickel-molybdenum-chromium alloy solution designed for extreme operational environments. Featuring a meticulously polished surface and exceptional resistance to high temperatures and corrosion, this tubing is engineered for critical applications in the oil & gas and pharmaceutical industries. Its superior performance stems from a unique composition that delivers unmatched reliability in handling aggressive media, ensuring safety, efficiency, and longevity in demanding processes.

Key Material Properties

Hastelloy C276 (UNS N10276) is renowned for its versatile durability, driven by its chemical composition and metallurgical characteristics:

-

Exceptional Corrosion Resistance: Resists a wide range of corrosive agents, including hydrochloric acid, sulfuric acid, hydrogen fluoride, phosphoric acid, organic acids, chlorine, and seawater5. It performs exceptionally well in both oxidizing and reducing environments, with heightened resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) induced by chlorides12.

-

High-Temperature Stability: Maintains mechanical integrity and corrosion resistance in temperatures up to 1000°C46, making it suitable for high-heat processes.

-

Polished Surface Finish: The tubing is available in polished surfaces (e.g., acid-pickled, bright-annealed, or mechanically polished), which enhances its resistance to contamination and facilitates easy cleaning—critical for pharmaceutical applications—while further improving corrosion resistance2.

-

Mechanical Strength: Offers high tensile strength (≥690 MPa), yield strength (≥283 MPa), and elongation (≥40%), ensuring durability under high-pressure conditions12.

Compliance with International Standards

Our precision tubing is manufactured in strict compliance with global standards to ensure reliability and performance:

-

ASTM B622: Standard for seamless nickel and nickel-cobalt alloy tubing.

-

ASTM B626: Standard for welded tubing.

-

Additional Certifications: Supplied with Mill Test Certificates (MTC) adhering to EN 10204 3.1, and support for third-party certifications (e.g., SGS, BV)2.

Applications in Oil & Gas and Pharmaceutical Industries

Oil & Gas Industry

In oil and gas operations, exposure to corrosive elements like H₂S, CO₂, chlorides, and high-pressure high-temperature (HPHT) conditions demands robust materials. Our C276 tubing is ideal for:

-

Downhole Instrumentation: Umbilicals and sensing lines resistant to sour gas and sulfide stress cracking.

-

Heat Exchangers and Condensers: Tubing that maintains integrity in corrosive and high-temperature environments3.

-

Process piping and components in refineries and offshore platforms, handling acidic crudes and corrosive gases2.

Pharmaceutical Industry

Pharmaceutical manufacturing requires ultra-clean, corrosion-resistant materials to ensure product purity and operational sterility. Our tubing is used in:

-

High-Purity Process Systems: Transfer lines for corrosive solvents, acids, and APIs (Active Pharmaceutical Ingredients).

-

Bioreactors and Fermenters: Jacketing and instrumentation tubing resisting cleaning agents like chlorinated sanitizers.

-

Sterilization Equipment: Components that withstand high-temperature steam and aggressive disinfectants without degrading.

Customization and Technical Specifications

We provide tailored solutions to meet specific operational needs:

-

Sizes: Outer Diameter (OD) from 6.35 mm to 406.4 mm; Wall Thickness from 0.508 mm to 50.8 mm2.

-

Lengths: Custom cut-to-length or long single lengths to minimize welds.

-

Surface Finish: Polished to specific Ra values (e.g., mechanical polish for smooth fluid transport).

-

Form: Seamless (for high-pressure applications) and welded (cost-effective for certain uses).

Quality Assurance and Testing

Every tube undergoes rigorous testing to guarantee performance:

-

Dimensional Checks: Laser micrometer verification of OD, ID, and wall thickness.

-

Non-Destructive Testing (NDT): Eddy Current Testing (ECT) and hydrostatic/pneumatic pressure tests.

-

Material Verification: Spark spectrometry for chemical composition; mechanical tests for tensile strength and hardness.

-

Surface Inspection: Ensure polish quality and defect-free surfaces.

Why Choose Our Hastelloy C276 Precision Tubing?

-

Industry-Specific Expertise: Deep understanding of oil & gas and pharmaceutical sector requirements.

-

Full Traceability: Documentation from melt to final product ensures material authenticity.

-

Global Support: Reliable logistics and technical assistance worldwide.

-

Competitive Pricing: Despite its premium properties, our tubing offers excellent value, with prices reflective of nickel and molybdenum market trends

![]()

![]()

![]()

![]()