Todos los productos

-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

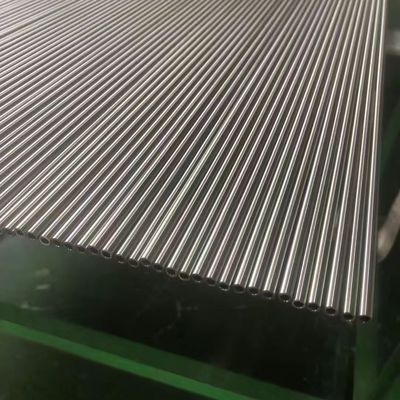

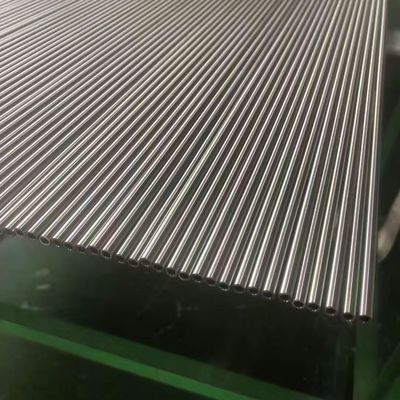

Bright Annealed Inconel 625 Pipe Diameter 6 - 89mm ASTM DIN EN JIS Standard Alloy 625

| Lugar de origen | China. |

|---|---|

| Nombre de la marca | DELTA |

| Certificación | ISO |

| Número de modelo | En el caso de los productos de la categoría 294 |

| Cantidad de orden mínima | 10 kg |

| Precio | 30 - 40 USD/Kg |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días basado en la cantidad |

| Condiciones de pago | L/C, T/T, Western Union |

| Capacidad de la fuente | 3 toneladas por semana |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

xDatos del producto

| Productos | Inconel 625 tuberías | Calificación | En el caso de los productos de la categoría 294 |

|---|---|---|---|

| Diámetro | 6 - 219 mm | Longitud | corte personalizado de cualquier longitud a petición |

| Estándar | ASTM EN | SERVICIO | Corte |

| Puerto de carga | Puerto de Shanghai | Superficie | Brillante |

| Resaltar | Inconel 625 pipe 6-89mm,ASTM standard Inconel 625 pipe,Nickel alloy bright annealed pipe |

||

Descripción de producto

Bright Annealed Inconel 625 Pipe Diameter 6 - 89mm ASTM DIN EN JIS Standard Alloy 625

More Specification Informations

| Products Name | Inconel 625 Pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

1. Key Technical Parameters

The technical parameters of bright annealed Inconel 625 pipes (6 - 89mm diameter) define their structural integrity and suitability for specific use cases, covering dimensions, material composition, and mechanical properties.

1.1 Dimensional Specifications

- Outer Diameter (OD): 6mm to 89mm (a versatile range that supports both low - flow precision systems, such as 6mm pipes for laboratory instrumentation, and higher - capacity industrial lines, like 89mm pipes for chemical processing).

- Wall Thickness: Typically ranges from 0.8mm to 6mm, with customization available based on pressure requirements. Thicker walls (e.g., 4 - 6mm) are used for high - pressure applications (e.g., oil and gas wellheads), while thinner walls (0.8 - 2mm) suit low - pressure fluid transfer (e.g., cooling loops).

- Length: Standard lengths include 3m, 6m, or 12m; cut - to - order lengths are also offered to minimize on - site waste.

- Surface Finish: Bright annealed (BA) finish, achieved via controlled heat treatment (annealing) followed by chemical or mechanical polishing. This results in a smooth, reflective surface (Ra ≤ 0.8μm) that reduces fluid friction, prevents material buildup, and enhances corrosion resistance.

1.2 Chemical Composition (Weight %)

Inconel 625’s performance is rooted in its precise alloy composition, which delivers corrosion resistance and high - temperature stability:

| Element | Content Range | Function |

|---|---|---|

| Nickel (Ni) | 58.0 min | Base metal; provides ductility and resistance to stress corrosion cracking. |

| Chromium (Cr) | 20.0 - 23.0 | Enhances oxidation resistance at high temperatures (up to 1093°C/2000°F). |

| Molybdenum (Mo) | 8.0 - 10.0 | Boosts resistance to pitting and crevice corrosion in chloride - rich environments (e.g., seawater, brines). |

| Niobium (Nb) + Tantalum (Ta) | 3.15 - 4.15 | Forms stable carbides; strengthens the alloy at high temperatures and prevents grain growth. |

| Iron (Fe) | 5.0 max | Minor impurity; controlled to avoid compromising corrosion resistance. |

| Carbon (C) | 0.10 max | Minimized to reduce carbide precipitation (which can weaken corrosion resistance in high - temperature service). |

| Silicon (Si) | 0.50 max | Aids in deoxidation during manufacturing; kept low to avoid brittleness. |

| Manganese (Mn) | 0.50 max | Improves hot workability; controlled to prevent oxidation. |

1.3 Mechanical Properties (After Bright Annealing)

Bright annealing relieves internal stresses and optimizes the alloy’s mechanical performance, making the pipes suitable for dynamic or high - pressure conditions:

- Tensile Strength: 827 MPa (120,000 psi) min.

- Yield Strength (0.2% Offset): 414 MPa (60,000 psi) min.

- Elongation (in 50mm): 30% min (ensures ductility for forming or bending without cracking).

- Hardness: ≤ 220 HB (Brinell) or ≤ 23 HRC (Rockwell C); the soft, ductile nature simplifies fabrication (e.g., welding, flanging).

2. Core Performance Advantages

Bright annealed Inconel 625 pipes stand out in demanding industries due to their synergistic performance traits, addressing key challenges like corrosion, high temperatures, and mechanical stress.

2.1 Exceptional Corrosion Resistance

- General Corrosion: Resists attack from organic acids (e.g., acetic acid), inorganic acids (e.g., sulfuric acid, nitric acid), and alkalis (e.g., sodium hydroxide), making it ideal for chemical processing.

- Localized Corrosion: Molybdenum and niobium inhibit pitting and crevice corrosion in aggressive media, such as seawater, salt sprays, and oilfield brines—critical for marine and offshore applications.

- Stress Corrosion Cracking (SCC): Nickel - rich composition prevents SCC in chloride or hydrogen sulfide (H₂S) environments, a common failure mode for lesser alloys (e.g., 316 stainless steel).

2.2 High - Temperature Stability

- Oxidation Resistance: Maintains structural integrity and resists scaling at temperatures up to 1093°C (2000°F) in air or oxidizing atmospheres, suitable for furnace components or exhaust systems.

- Creep Resistance: Retains strength under long - term exposure to high temperatures and mechanical loads (e.g., 650°C/1200°F for 10,000 hours), preventing deformation in power generation turbines or heat exchangers.

2.3 Enhanced Fabricability & Durability

- Bright Annealing Benefits: The annealing process eliminates residual stresses from manufacturing (e.g., extrusion, drawing), reducing the risk of cracking during welding or installation. The smooth BA surface also minimizes fluid turbulence and fouling, extending the pipe’s service life.

- Weldability: Compatible with common welding methods (TIG, MIG, SMAW) without losing corrosion or mechanical properties. Post - weld heat treatment is often unnecessary, simplifying on - site assembly.

3. Compliance with International Standards

Adherence to global standards ensures that bright annealed Inconel 625 pipes meet consistent quality, safety, and performance criteria for cross - industry and international projects. The table below outlines key standards for different regions:

| Standard System | Relevant Standards | Key Requirements Covered |

|---|---|---|

| ASTM (USA) | ASTM B444 | Specifies seamless nickel - alloy pipes; covers dimensions, chemical composition, mechanical properties, and non - destructive testing (NDT, e.g., ultrasonic testing for wall thickness). |

| ASTM B751 | Governs bright annealed nickel - alloy tubes; focuses on surface finish, dimensional tolerance, and annealing process controls. | |

| DIN (Germany) | DIN 17752 | Specifies seamless pipes for high - temperature and corrosion - resistant applications; includes chemical analysis and tensile testing requirements. |

| EN (EU) | EN 10216 - 5 | Part of the European standard for seamless steel pipes; covers nickel and nickel - alloy pipes, including Inconel 625, with provisions for pressure ratings and NDT. |

| JIS (Japan) | JIS G3463 | Japanese standard for nickel and nickel - alloy seamless pipes; mandates compliance with chemical composition, mechanical properties, and surface quality (e.g., no scratches or pits). |

4. Equivalent Grades

Inconel 625 is recognized under different designations across global standards and manufacturers. These equivalent grades offer similar performance and can be used interchangeably in most applications:

- ASTM/ASME: UNS N06625, W.Nr. 2.4856 (German material number).

- EN: NiCr22Mo9Nb (European designation).

- JIS: NW6625 (Japanese Industrial Standard).

- Other Trade Names: Haynes 625, Alloy 625 (generic industry terms).

Note: While these grades are equivalent in composition and performance, always verify compatibility with specific project standards (e.g., ASME BPVC for pressure vessels) before substitution.

5. Typical Applications

The 6 - 89mm diameter range and performance of bright annealed Inconel 625 pipes make them indispensable in industries where reliability, corrosion resistance, and high - temperature performance are non - negotiable. Key applications include:

5.1 Chemical & Petrochemical Industry

- Used for pipes in acid processing (e.g., sulfuric acid, hydrochloric acid), chemical reactors, and catalyst regeneration systems. The 10 - 50mm diameter pipes are common for transferring corrosive fluids, while 60 - 89mm pipes suit larger - volume reactor feed lines.

5.2 Oil & Gas (Upstream & Downstream)

- Upstream: Pipes for offshore wellheads, subsea manifolds, and production tubing (resists seawater corrosion and H₂S in sour gas wells). The 20 - 70mm diameter range is typical for wellhead chokes and flowlines.

- Downstream: Refinery pipes for hydrocracking units and desulfurization processes (withstands high temperatures and sulfur - rich environments).

5.3 Marine & Offshore Engineering

- Applied in seawater cooling systems, offshore platform piping, and shipboard hydraulic lines. The bright annealed surface prevents marine organism fouling, while corrosion resistance ensures longevity in saltwater. 6 - 30mm pipes are used for cooling loops, and 40 - 89mm pipes for main seawater intake lines.

5.4 Power Generation

- Used in fossil fuel power plants (for flue gas desulfurization systems) and nuclear power plants (for coolant pipes in secondary loops). The alloy’s creep resistance makes it suitable for high - temperature steam lines (50 - 89mm diameter).

5.5 Aerospace & Defense

- Small - diameter pipes (6 - 20mm) are used in aircraft engine fuel lines, hydraulic systems, and rocket propulsion components. The bright surface reduces fluid friction, while high - temperature resistance withstands engine heat (up to 980°C/1800°F).

5.6 Medical & Pharmaceutical

- Employed in pharmaceutical manufacturing for sterile fluid transfer (e.g., drug synthesis, vaccine production) and medical device components (e.g., surgical instruments). The smooth BA surface is easy to clean and sterilize, complying with FDA and EMA regulations.

![]()

![]()

![]()

![]()

Productos recomendados