All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

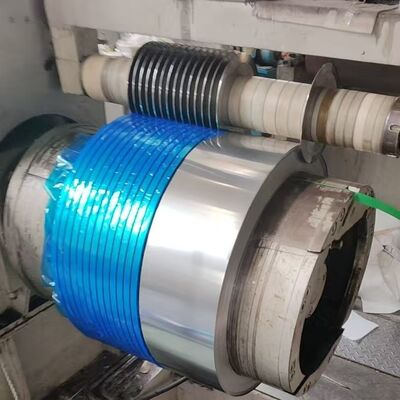

High-Quality 304 Stainless Steel Strip – Corrosion-Resistant & Durable for Industrial Applications

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL POSCO |

| Certification | ISO |

| Model Number | 201 304 309S 310S 316L 317L 321 347 410 420 430.etc |

| Minimum Order Quantity | 2 Ton |

| Price | 1800-2000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Product Details

| Products | Stainless Steel Coil | Material | Stainless Steel |

|---|---|---|---|

| Thickness | 0.1 - 3.0mm | Width | 1000mm 1219mm 1500mm |

| Surface | 2B NO.1 NO.4 8K | Grade | 201 304 309S 310S 316L 317L 321 347 410 420 430 436 439 441 444.etc |

| Standard | ASTM EN GB JIS | Service | Cutting |

| Highlight | 304 stainless steel strip industrial,corrosion resistant stainless steel strip,durable 304 stainless steel strip |

||

Product Description

High-Quality 304 Stainless Steel Strip – Corrosion-Resistant & Durable for Industrial Applications

Products Specification

|

Products Name:

|

Stainless steel Coil

|

|||

|

Thickness:

|

0.1 mm - 10.0 mm

|

|||

|

Inner Diameter

|

508mm

|

|||

|

Width:

|

1000mm, 1219mm, customized max width 1500mm

|

|||

|

SS Grade:

|

201 202 301 304 304L 309S 310S 316L 316Ti 317L 409L 410 420 436L 439 441 444

2205 2507 904L C276 600 625 825 926.etc

|

|||

|

Coil surfaces:

|

2B, No.1, BA, Mirror, Hairline, No.4, PVD

|

|||

|

Available finishes:

|

No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination etc.

|

|||

|

Standard:

|

JIS, AISI,ASTM,GB,DIN

|

|||

|

Packing way:

|

PVC+ waterproof paper + strong sea-worthy wooden package

|

|||

High-Quality 304 Stainless Steel Strip – Corrosion-Resistant & Durable for Industrial Applications

Product Overview

Our high-quality 304 stainless steel strip is engineered to deliver exceptional performance in demanding industrial environments. Made from premium-grade AISI 304 (UNS S30400)—also known as SUS304 (JIS) or 1.4301 (EN)—this cold-rolled strip combines outstanding corrosion resistance, mechanical strength, and formability in a versatile, thin-gauge format. Available in thicknesses from 0.1 mm to 3.0 mm with a smooth 2B surface finish, it is ideal for precision manufacturing across sectors including automotive, electronics, medical devices, food processing, and renewable energy.

Every coil undergoes stringent quality control to ensure dimensional accuracy, edge integrity, and long-term durability—making it a trusted choice for engineers and OEMs worldwide.

Why Choose 304 Stainless Steel?

Grade 304 is the most widely used austenitic stainless steel due to its balanced composition of 18% chromium and 8% nickel, which provides:

- Superior resistance to oxidation, organic acids, and atmospheric corrosion

- Excellent weldability and formability without post-weld annealing

- Non-magnetic properties in the annealed condition (ideal for sensitive electronics)

- Compliance with FDA, NSF, and EU hygiene standards for food and medical use

Whether exposed to humid coastal air, chemical cleaners, or high-temperature processes, 304 stainless steel maintains structural integrity and aesthetic finish over time.

Key Product Features

| Feature | Specification |

|---|---|

| Material Grade | AISI 304 / SUS304 / EN 1.4301 |

| Form | Cold-rolled strip or coil |

| Thickness Range | 0.1 mm – 3.0 mm (custom tolerances available) |

| Width Options | 5 mm – 650 mm (precision slit-to-width) |

| Surface Finish | 2B (standard); optional BA, No.4, or brushed |

| Edge Quality | Precision-slit, burr-free, Ra ≤ 0.8 µm |

| Tolerance (Thickness) | ±0.005 mm (for 0.1–0.5 mm), ±0.02 mm (for 0.5–3.0 mm) |

| Standards | ASTM A666, JIS G4305, EN 10088-2 |

| Certifications | ISO 9001, RoHS, REACH, Material Test Report (MTR/EN 10204 3.1) |

| Packaging | VCI anti-rust paper + PE film + wooden pallet (export-ready) |

Chemical Composition (ASTM A240)

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Silicon (Si) | ≤ 0.75 |

| Chromium (Cr) | 18.0 – 20.0 |

| Nickel (Ni) | 8.0 – 10.5 |

| Iron (Fe) | Balance |

This composition ensures a stable austenitic microstructure, enabling excellent ductility (elongation ≥ 40%) and resistance to intergranular corrosion.

Mechanical Properties (Annealed Condition)

| Property | Typical Value |

|---|---|

| Tensile Strength | 515–690 MPa |

| Yield Strength (0.2% offset) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (Rockwell B) | 70–85 HRB |

| Density | 7.93 g/cm³ |

| Melting Range | 1400–1450°C |

These properties support deep drawing, bending, stamping, and laser cutting—without cracking or excessive work hardening—when proper tooling and lubrication are used.

The 2B Surface Finish Advantage

The 2B finish is the industry-standard mill finish for cold-rolled stainless steel, achieved through:

- Cold rolling

- Annealing in a controlled atmosphere

- Pickling to remove scale

- Light skin-pass rolling for smoothness

Benefits of 2B finish:

- Uniform, semi-bright matte appearance

- Excellent flatness and surface cleanliness

- Ideal base for secondary finishes (e.g., polishing, coating)

- Resists fingerprint smudging better than bright-annealed (BA) finishes

- Meets hygiene requirements for food-contact surfaces

Unlike rougher finishes (e.g., No.1 or 2D), 2B minimizes micro-pits that could trap contaminants—critical in cleanroom or sterile environments.

Burr-Free Precision Cutting: Critical for Modern Manufacturing

In automated assembly lines, robotics, or micro-component production, even microscopic burrs can cause:

- Equipment jams or sensor malfunctions

- Electrical arcing in battery tabs or connectors

- Contamination in pharmaceutical or semiconductor processes

- Reduced fatigue life in dynamic components

Our state-of-the-art precision slitting line uses diamond-coated blades and real-time laser monitoring to deliver clean, smooth edges with zero micro-burrs. Every batch is inspected using optical profilometry to guarantee edge quality.

Industry Applications

| Industry | Typical Uses |

|---|---|

| Electronics | Battery current collectors, EMI/RFI shielding, flexible PCB supports, spring contacts |

| Medical | Surgical instrument components, implant housings, diagnostic device frames |

| Automotive | Fuel system parts, sensor brackets, exhaust gaskets, EV battery interconnects |

| Food & Beverage | Conveyor components, filling nozzles, mixing blades, sanitary panels |

| Renewable Energy | Solar mounting clips, hydrogen fuel cell bipolar plates, wind turbine sensors |

| Industrial Machinery | Wear strips, shims, spacers, springs, filtration mesh |

Quality Assurance & Traceability

We maintain full traceability from melt to shipment:

- Each coil tagged with heat number and batch ID

- Mill Test Reports (MTR) provided with every order (EN 10204 3.1)

- In-house lab testing for chemistry, tensile strength, and surface roughness

- Optional third-party inspection (SGS, Bureau Veritas) available

Our facility is ISO 9001:2015 certified, with continuous process monitoring to minimize variation across production runs.

Ordering Information

- Minimum Order Quantity (MOQ): 50 kg for standard sizes; 200 kg for custom widths

- Lead Time: 7–15 days (stock items); 20–30 days for large/custom orders

- Delivery Terms: FOB, CIF, or DDP—global shipping via air, sea, or land

- Custom Services: Cut-to-length, edge rounding, protective film lamination, kitting

We support prototype sampling and JIT (Just-in-Time) delivery programs for high-volume customers.

Frequently Asked Questions (FAQ)

Q: Is 304 stainless steel suitable for marine environments?

A: While 304 offers good general corrosion resistance, 316 stainless steel is recommended for prolonged saltwater exposure due to its molybdenum content.

A: While 304 offers good general corrosion resistance, 316 stainless steel is recommended for prolonged saltwater exposure due to its molybdenum content.

Q: Can you supply strips with tighter thickness tolerances?

A: Yes—for ultra-thin gauges (<0.2 mm), we offer ±0.002 mm tolerance using precision rolling mills.

A: Yes—for ultra-thin gauges (<0.2 mm), we offer ±0.002 mm tolerance using precision rolling mills.

Q: Do you provide material certifications?

A: Absolutely. All shipments include chemical composition reports and mechanical test data.

A: Absolutely. All shipments include chemical composition reports and mechanical test data.

Q: What’s the difference between 304 and 304L?

A: 304L has lower carbon content (≤0.03%) to prevent carbide precipitation during welding—ideal for heavy welded structures. For most strip applications, standard 304 is sufficient.

A: 304L has lower carbon content (≤0.03%) to prevent carbide precipitation during welding—ideal for heavy welded structures. For most strip applications, standard 304 is sufficient.

Conclusion

When reliability, longevity, and precision matter, our high-quality 304 stainless steel strip stands out as a superior solution for modern industrial challenges. Backed by rigorous quality systems, global compliance, and engineering support, we help you reduce downtime, improve product performance, and meet sustainability goals through durable, recyclable materials.

304 stainless steel strip, corrosion-resistant stainless coil, industrial stainless steel strip, cold rolled 304 strip, 2B finish stainless steel, precision slit stainless, burr-free 304 strip, thin gauge stainless steel, AISI 304 coil, stainless steel for electronics, medical grade 304, high-quality stainless strip, 0.1mm stainless steel tape, durable stainless steel for machinery.

Recommended Products