-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

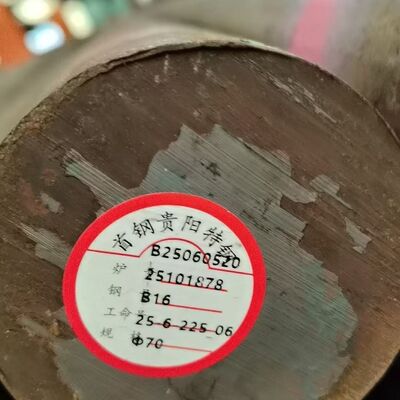

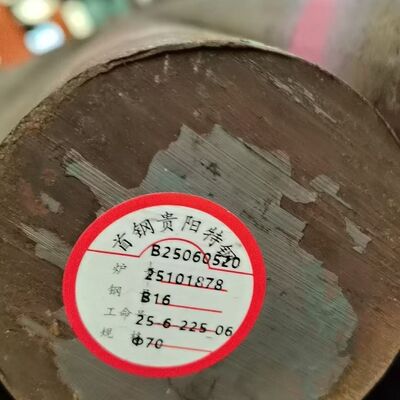

ASTM B193 B16 Alloy Round Bar Diameter 20 - 350mm for Bolt Structure Custom Cutting in Length

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | Alloy Steel Round Bar | Diameter | 10 - 450mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

ASTM B193 B16 Alloy Round Bar Diameter 20 - 350mm for Bolt Structure Custom Cutting in Length

Products Specification

|

Products Name |

B16 Alloy Steel Round Bar |

|

Diameter |

10 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,B16,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Product Overview

Key Features & Benefits

- ✅ High-Temperature Strength: Maintains mechanical properties up to 540°C (1000°F)

- ✅ Excellent Creep & Rupture Resistance: Ideal for long-term service in elevated temperature environments

- ✅ Quenched & Tempered (Q&T): Heat-treated to achieve optimal hardness and toughness

- ✅ Precise Dimensional Tolerances: Ground or peeled surface finish available upon request

- ✅ Custom Length Cutting: Minimizes waste and reduces machining time

- ✅ Traceable Mill Test Reports (MTRs): Full compliance with ASTM, ASME, and NACE standards

Chemical Composition (ASTM A193 Grade B16)

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.36 – 0.47 |

| Manganese (Mn) | 0.45 – 0.70 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

| Silicon (Si) | 0.15 – 0.35 |

| Chromium (Cr) | 0.80 – 1.15 |

| Molybdenum (Mo) | 0.50 – 0.65 |

| Vanadium (V) | 0.25 – 0.35 |

| Aluminum (Al) | ≤ 0.015 |

Mechanical Properties

| Property | Requirement |

|---|---|

| Tensile Strength | ≥ 862 MPa (125 ksi) |

| Yield Strength (0.2% Offset) | ≥ 725 MPa (105 ksi) |

| Elongation (in 4D) | ≥ 32% |

| Reduction of Area | ≥ 35% |

| Hardness | ≤ 35 HRC (≈ 321 HB max) |

Heat Treatment Process

- Austenitizing: Heated to ~870–925°C (1600–1700°F)

- Quenching: Rapidly cooled in oil or water

- Tempering: Reheated to minimum 649°C (1200°F) and held for sufficient time to achieve desired mechanical properties

Product Specifications

| Parameter | Details |

|---|---|

| Standard | ASTM A193 / A193M (Grade B16) |

| Equivalent Grades | UNS K11547, DIN 1.7734, Chinese 40CrMoV |

| Diameter Range | 20 mm – 350 mm (0.79" – 13.78") |

| Length Options | Standard: 3m, 6m; Custom cut-to-length available (min. 500 mm) |

| Surface Finish | Black hot-rolled, peeled, turned, or ground (upon request) |

| Tolerance | Per ASTM A484 or ISO 286 (h9/h11 as standard) |

| Certification | EN 10204 3.1 / 3.2, Mill Test Report (MTR), Chemical & Mechanical Reports |

| Packaging | Bundled with steel straps, waterproof wrapping, wooden crates for export |

Common Applications

- Steam turbine bolts & studs (high-pressure sections)

- Flange fasteners in refineries and chemical plants

- Pressure vessel closures and manway bolts

- Superheater headers and boiler connections

- Power plant piping systems (main steam lines)

- Offshore & onshore oil & gas wellhead assemblies

Why Choose Our ASTM A193 B16 Round Bars?

- Strict Quality Control: Every batch is tested per ASTM E8 (tensile), E18 (hardness), and E45 (inclusion rating).

- Global Compliance: Materials meet ASME BPVC Section II, NACE MR0175/ISO 15156 (for sour service when required).

- Customization: We cut to your exact length—whether 1,250 mm for turbine studs or 4,800 mm for anchor bolts.

- Fast Lead Time: Stock available in major diameters (20–150 mm); larger sizes (151–350 mm) produced within 4–6 weeks.

- Technical Support: Our metallurgical team provides guidance on heat treatment, threading, and installation best practices.

Ordering Information

- Required diameter (e.g., 50 mm, 120 mm, 250 mm)

- Total length or cut lengths (e.g., “cut to 2,000 mm ±2 mm”)

- Quantity (in metric tons or pieces)

- Surface finish preference

- Certification requirements (e.g., 3.1, PMI test, UT inspection)

- Destination port (for FOB/CIF pricing)

FAQs

A: Yes—it’s a ferritic alloy steel and exhibits magnetic properties.

A: Welding is possible but requires preheating (~200–300°C) and post-weld heat treatment (PWHT) to avoid cracking. Consult a welding procedure specification (WPS).

A: B7 (4140-based) is suitable up to ~400°C, while B16 (with added vanadium) offers better creep resistance above 450°C and is used in more severe thermal cycles.

A: Yes—we recommend ASTM A194 Grade 16 heavy hex nuts and ASTM F436 hardened washers for full system compatibility.