-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

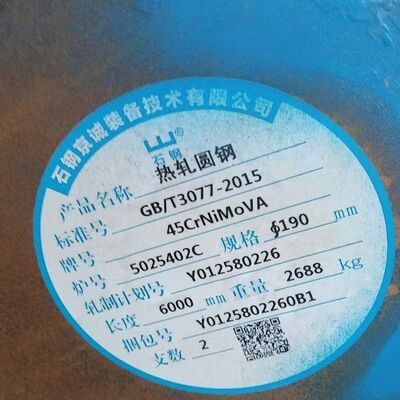

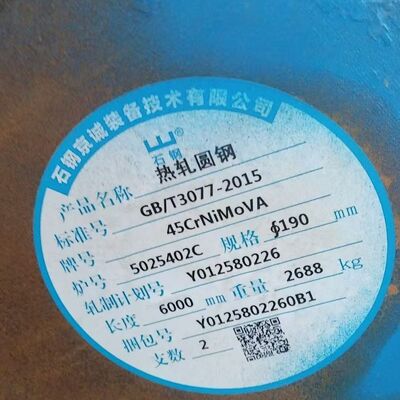

Quenched & Tempered 45CrNiMoVA Alloy Structural Steel Round Bar

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | Alloy Steel Round Bar | Diameter | 10 - 450mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

Quenched & Tempered 45CrNiMoVA Alloy Structural Steel Round Bar

Products Specification

|

Products Name |

45CrNiMoVA Alloy Steel Round Bar |

|

Diameter |

10 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Quenched & Tempered 45CrNiMoVA Alloy Structural Steel Round Bar

Overview

Quenched & Tempered 45CrNiMoVA Alloy Structural Steel Round Bar is a high-performance alloy steel product widely used in demanding mechanical and structural applications. Known for its excellent combination of high strength, toughness, wear resistance, and fatigue performance, 45CrNiMoVA steel is especially suitable for components that must operate under heavy loads, high stress, and complex working conditions.

After quenching and tempering (Q&T) heat treatment, this alloy steel achieves a refined microstructure that significantly enhances its mechanical properties while maintaining good machinability. These characteristics make 45CrNiMoVA round bars a reliable material choice for industries such as heavy machinery, automotive manufacturing, aerospace, energy, and defense.

This page provides a comprehensive introduction to the chemical composition, mechanical properties, heat treatment process, dimensions, applications, and advantages of 45CrNiMoVA alloy structural steel round bars, optimized to meet Google search and SEO standards.

What Is 45CrNiMoVA Alloy Structural Steel?

45CrNiMoVA is a medium-carbon, low-alloy structural steel enhanced with chromium (Cr), nickel (Ni), molybdenum (Mo), and vanadium (V). Each alloying element plays a specific role:

-

Chromium (Cr): Improves hardenability and corrosion resistance

-

Nickel (Ni): Enhances toughness and impact resistance

-

Molybdenum (Mo): Increases high-temperature strength and fatigue resistance

-

Vanadium (V): Refines grain size and improves wear resistance

When supplied in the quenched and tempered condition, 45CrNiMoVA steel round bars offer an optimal balance between strength and ductility.

Key Features and Benefits

-

High tensile and yield strength

-

Excellent impact toughness, even at low temperatures

-

Superior hardenability and uniform mechanical properties

-

Good resistance to wear and fatigue

-

Stable performance under dynamic and heavy loads

-

Suitable for precision machining after heat treatment

Chemical Composition of 45CrNiMoVA Steel

The chemical composition is carefully controlled to ensure consistent performance and reliability.

| Element | C | Si | Mn | Cr | Ni | Mo | V | P | S |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.42–0.50 | 0.17–0.37 | 0.50–0.80 | 0.90–1.20 | 1.30–1.70 | 0.20–0.30 | 0.05–0.12 | ≤0.025 | ≤0.025 |

Note: Exact composition may vary slightly depending on specific standards or customer requirements.

Mechanical Properties (Quenched & Tempered Condition)

After proper quenching and tempering, 45CrNiMoVA round bars exhibit excellent mechanical performance:

| Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | ≥ 980 |

| Yield Strength (MPa) | ≥ 835 |

| Elongation (%) | ≥ 12 |

| Reduction of Area (%) | ≥ 50 |

| Impact Energy (Charpy, J) | ≥ 63 |

| Hardness (HB) | 269–321 |

These properties make the material ideal for parts subjected to high cyclic stress and shock loading.

Heat Treatment Process

The quenched and tempered (Q&T) process is critical to achieving the desired performance of 45CrNiMoVA alloy steel.

Typical Heat Treatment Parameters

-

Quenching

-

Heating temperature: 850–880°C

-

Cooling medium: Oil or polymer quenching

-

-

Tempering

-

Tempering temperature: 560–650°C

-

Cooling method: Air cooling

-

This process produces a tempered martensitic structure, ensuring high strength while avoiding excessive brittleness.

Available Dimensions and Specifications

45CrNiMoVA alloy structural steel round bars are available in a wide range of sizes to meet different engineering needs.

| Parameter | Range |

|---|---|

| Diameter | 20 mm – 800 mm |

| Length | 3,000 mm – 12,000 mm |

| Supply Condition | Quenched & Tempered |

| Surface Finish | Black, Peeled, Turned, or Polished |

| Standards | GB, ASTM, EN, DIN (customized available) |

Custom sizes and special tolerances can be supplied upon request.

Applications of 45CrNiMoVA Alloy Steel Round Bar

Thanks to its excellent mechanical properties, 45CrNiMoVA steel is widely used in critical components where reliability and durability are essential.

Typical Applications

-

Heavy-duty shafts and transmission shafts

-

Gears and gear shafts

-

Large bolts and fasteners

-

Crankshafts and connecting rods

-

Hydraulic piston rods

-

Aerospace and defense structural components

-

Mining and construction machinery parts

Its ability to maintain strength and toughness under extreme working conditions makes it a preferred material in high-end equipment manufacturing.

Machinability and Weldability

Machinability

In the quenched and tempered state, 45CrNiMoVA steel offers good machinability with appropriate cutting tools. Carbide tools are recommended for higher efficiency and better surface finish.

Weldability

Due to its alloy content and medium carbon level, preheating and post-weld heat treatment are recommended to avoid cracking and ensure joint integrity. Welding procedures should be carefully controlled.

Quality Control and Inspection

To ensure consistent quality, 45CrNiMoVA alloy steel round bars typically undergo:

-

Chemical composition analysis

-

Mechanical property testing

-

Ultrasonic testing (UT)

-

Magnetic particle inspection (MPI), if required

-

Dimensional and surface inspection

All products can be supplied with mill test certificates (MTC) in accordance with EN 10204 3.1 or equivalent standards.

Why Choose Quenched & Tempered 45CrNiMoVA Round Bar?

Compared with conventional carbon steels or low-alloy steels, 45CrNiMoVA offers:

-

Longer service life

-

Higher safety margin in critical components

-

Reduced maintenance and replacement costs

-

Reliable performance in extreme environments

These advantages translate into lower total lifecycle cost for end users.

Conclusion

Quenched & Tempered 45CrNiMoVA Alloy Structural Steel Round Bar is a premium material engineered for strength, toughness, and durability. With its optimized chemical composition, excellent mechanical properties, and wide range of applications, it stands out as an ideal choice for high-stress and heavy-duty engineering components.

Whether used in machinery manufacturing, energy equipment, or advanced industrial systems, 45CrNiMoVA steel round bars deliver consistent quality, superior performance, and long-term reliability—making them a trusted solution for modern engineering challenges.

![]()

![]()

![]()

![]()