-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

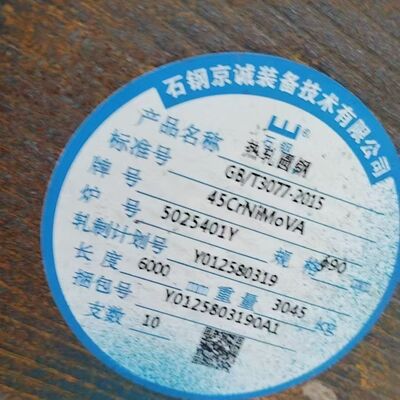

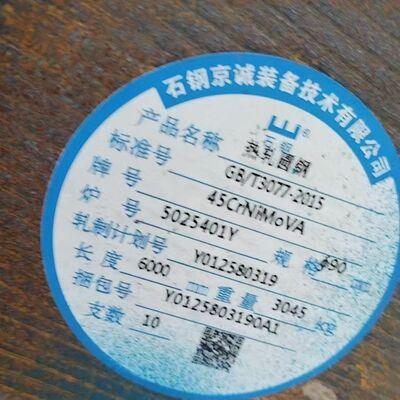

Hot Rolled Diameter 10 - 350mm Alloy 45CrNiMoVA Chromium-Nickel-Molybdenum-Vanadium Alloy Round Steel

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | Alloy Steel Round Bar | Diameter | 10 - 450mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

Hot Rolled Diameter 10 - 350mm Alloy 45CrNiMoVA Chromium-Nickel-Molybdenum-Vanadium Alloy Round Steel

Products Specification

|

Products Name |

45CrNiMoVA Alloy Steel Round Bar |

|

Diameter |

10 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Hot Rolled Diameter 10 - 350mm Alloy 45CrNiMoVA Chromium-Nickel-Molybdenum-Vanadium Alloy Round Steel

Product Overview

45CrNiMoVA Alloy Round Steel is a high-performance chromium-nickel-molybdenum-vanadium alloy steel known for its excellent strength, toughness, hardenability, and fatigue resistance. Produced through advanced hot rolling processes, this alloy round bar is widely used in heavy-duty mechanical components, aerospace structures, military equipment, and high-stress industrial applications.

With a hot rolled diameter range from 10 mm to 350 mm, 45CrNiMoVA alloy round steel offers excellent versatility for machining, forging, and heat treatment. The balanced alloy composition ensures superior mechanical properties, making it an ideal material for components that require high reliability under extreme working conditions.

Key Features of 45CrNiMoVA Alloy Round Steel

-

Excellent high strength and toughness combination

-

Superior hardenability and deep hardening capability

-

Outstanding fatigue resistance and impact performance

-

Good wear resistance and thermal stability

-

Reliable performance under high load and high stress

-

Suitable for quenching, tempering, and surface hardening

Chemical Composition

The chemical composition of 45CrNiMoVA alloy steel is carefully controlled to ensure consistent performance and quality. The addition of chromium, nickel, molybdenum, and vanadium significantly improves strength, toughness, and resistance to fatigue and wear.

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.42 – 0.49 |

| Silicon (Si) | ≤ 0.40 |

| Manganese (Mn) | 0.50 – 0.80 |

| Chromium (Cr) | 0.90 – 1.20 |

| Nickel (Ni) | 1.40 – 1.70 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Vanadium (V) | 0.05 – 0.12 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

Mechanical Properties

After appropriate heat treatment (quenching and tempering), 45CrNiMoVA alloy round steel exhibits excellent mechanical properties suitable for demanding structural and mechanical applications.

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 980 MPa |

| Yield Strength | ≥ 835 MPa |

| Elongation | ≥ 12% |

| Reduction of Area | ≥ 45% |

| Impact Toughness (Charpy V) | ≥ 63 J |

| Hardness (HB) | 285 – 341 |

Note: Mechanical properties may vary depending on heat treatment and section size.

Available Sizes and Delivery Condition

45CrNiMoVA alloy round steel is available in a wide range of diameters to meet different application requirements.

Diameter Range

-

Hot Rolled Round Bars: 10 mm – 350 mm

-

Custom sizes available upon request

Delivery Condition

-

Hot Rolled

-

Annealed

-

Normalized

-

Quenched and Tempered (Q&T)

-

Machined or Peeled (optional)

Heat Treatment Process

Proper heat treatment is essential to fully utilize the performance advantages of 45CrNiMoVA alloy round steel.

Typical Heat Treatment Parameters

| Process | Temperature (°C) | Description |

|---|---|---|

| Annealing | 830 – 860 | Improve machinability |

| Quenching | 850 – 880 | Oil quenching |

| Tempering | 540 – 680 | Achieve optimal strength and toughness |

After quenching and tempering, the steel achieves a refined microstructure with excellent mechanical stability.

Applications of 45CrNiMoVA Alloy Round Steel

Thanks to its outstanding mechanical properties, 45CrNiMoVA alloy round steel is widely used in industries that demand high strength, durability, and reliability.

Typical Applications Include:

-

Aircraft landing gear components

-

Heavy-duty shafts and spindles

-

Gears and transmission parts

-

High-strength bolts and fasteners

-

Military equipment and weapon components

-

Forged dies and molds

-

Oil and gas drilling tools

-

Large mechanical structural parts

Advantages Compared with Conventional Alloy Steels

Compared with standard alloy steels such as 42CrMo or 40Cr, 45CrNiMoVA alloy steel offers superior comprehensive performance.

| Property | 45CrNiMoVA | 42CrMo |

|---|---|---|

| Strength | Higher | Medium |

| Toughness | Excellent | Good |

| Hardenability | Excellent | Good |

| Fatigue Resistance | Excellent | Medium |

| Impact Performance | Excellent | Good |

This makes 45CrNiMoVA particularly suitable for critical components subjected to alternating loads and harsh operating conditions.

Quality Control and Inspection

To ensure consistent quality and performance, 45CrNiMoVA alloy round steel undergoes strict quality control procedures throughout the production process.

Inspection Methods

-

Chemical composition analysis

-

Ultrasonic testing (UT)

-

Mechanical property testing

-

Hardness testing

-

Surface inspection

-

Dimensional inspection

Each batch is supplied with a Mill Test Certificate (MTC) in accordance with EN 10204 3.1 or customer requirements.

Packaging and Delivery

-

Bundled with steel straps or wooden cases

-

Anti-rust treatment available

-

Suitable for sea, land, and air transportation

-

Custom packaging upon request

Why Choose Our 45CrNiMoVA Alloy Round Steel?

-

Stable and reliable material quality

-

Wide diameter range from 10 mm to 350 mm

-

Advanced hot rolling and heat treatment technology

-

Strict quality inspection system

-

Fast delivery and flexible customization

-

Professional technical support

Conclusion

Hot Rolled Diameter 10 - 350mm Alloy 45CrNiMoVA Chromium-Nickel-Molybdenum-Vanadium Alloy Round Steel is an ideal choice for high-load, high-stress, and safety-critical applications. With its excellent mechanical properties, superior fatigue resistance, and reliable performance, 45CrNiMoVA alloy round steel provides long-term value and dependable service in demanding industrial environments.

![]()

![]()

![]()

![]()