-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

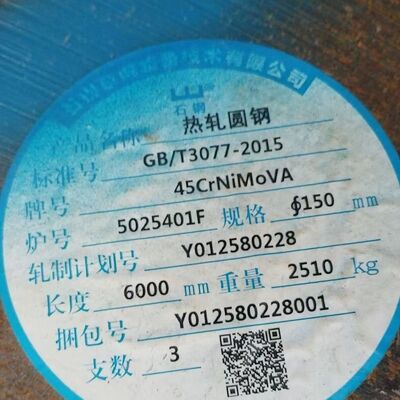

Hot Rolled 45CrNiMoVA Alloy Steel Round Bar for Heavy-Duty Applications Custom Cutting in Length

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | Alloy Steel Round Bar | Diameter | 10 - 450mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

Hot Rolled 45CrNiMoVA Alloy Steel Round Bar for Heavy-Duty Applications Custom Cutting in Length

Products Specification

|

Products Name |

45CrNiMoVA Alloy Steel Round Bar |

|

Diameter |

10 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Hot Rolled 45CrNiMoVA Alloy Steel Round Bar for Heavy-Duty Applications – Custom Cutting in Length

Product Overview

The Hot Rolled 45CrNiMoVA Alloy Steel Round Bar is a high-performance structural steel product engineered for heavy-duty mechanical and industrial applications. With an optimized chemical composition including Chromium (Cr), Nickel (Ni), Molybdenum (Mo), and Vanadium (V), 45CrNiMoVA steel offers an excellent balance of high strength, toughness, wear resistance, and fatigue performance.

Manufactured through controlled hot rolling and optional heat treatment processes, this alloy steel round bar is widely used in mining machinery, heavy equipment, power transmission components, forging dies, shafts, gears, and pressure-bearing parts. We offer custom cutting in length to meet diverse project requirements, improving material utilization and reducing machining costs.

Key Advantages of 45CrNiMoVA Alloy Steel

45CrNiMoVA is a medium-carbon low-alloy steel designed for demanding working conditions. Compared with standard carbon steels, it delivers superior mechanical properties and long-term service reliability.

Main Benefits

-

High tensile and yield strength after quenching and tempering

-

Excellent impact toughness, even under heavy load

-

Improved hardenability due to Ni, Cr, and Mo alloying

-

Enhanced wear and fatigue resistance with vanadium refinement

-

Good machinability in annealed or normalized condition

-

Stable performance in large cross-section components

These advantages make 45CrNiMoVA alloy round bars an ideal choice for applications where safety, durability, and structural integrity are critical.

Chemical Composition (Typical)

The carefully balanced chemical composition ensures consistent mechanical performance and reliable heat treatment response.

| Element | C | Si | Mn | Cr | Ni | Mo | V | P | S |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.42–0.49 | 0.17–0.37 | 0.50–0.80 | 0.90–1.20 | 0.80–1.10 | 0.15–0.30 | 0.05–0.12 | ≤0.025 | ≤0.025 |

Note: Exact composition can be adjusted based on customer requirements and applicable standards.

Mechanical Properties (After Heat Treatment)

When quenched and tempered, 45CrNiMoVA steel exhibits outstanding mechanical strength and toughness suitable for heavy-duty use.

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 980 MPa |

| Yield Strength | ≥ 835 MPa |

| Elongation | ≥ 12% |

| Reduction of Area | ≥ 45% |

| Impact Energy (–20°C) | ≥ 47 J |

| Hardness (HB) | 285–341 |

These properties ensure excellent resistance to shock loading, cyclic stress, and long-term fatigue, even in harsh industrial environments.

Available Sizes and Specifications

Our hot rolled 45CrNiMoVA alloy steel round bars are available in a wide range of dimensions to meet global industrial standards.

Standard Size Range

| Item | Specification |

|---|---|

| Diameter | Ø20 mm – Ø350 mm |

| Length | 6 m (custom cutting available) |

| Surface Condition | Black (hot rolled), peeled, or machined |

| Delivery Condition | Hot rolled, normalized, annealed, Q&T |

| Straightness | As per standard or customer request |

Custom cutting in length is available to minimize waste and improve processing efficiency for your specific application.

Manufacturing Process

The production of 45CrNiMoVA alloy steel round bars follows strict quality control procedures:

-

Electric arc furnace (EAF) or vacuum melting for chemical stability

-

Refining and alloy adjustment to ensure uniform composition

-

Hot rolling with controlled deformation

-

Optional heat treatment (normalizing, quenching & tempering)

-

Ultrasonic testing (UT) for internal quality assurance

-

Dimensional inspection and surface quality control

This process guarantees internal soundness, uniform grain structure, and stable performance in demanding applications.

Heat Treatment Options

To meet different working conditions, multiple heat treatment solutions are available:

| Heat Treatment | Purpose |

|---|---|

| Annealing | Improve machinability, reduce hardness |

| Normalizing | Refine grain structure, improve uniformity |

| Quenching & Tempering | Achieve high strength and toughness |

| Stress Relieving | Reduce internal stress after machining |

Heat treatment parameters can be customized according to drawing requirements or end-use conditions.

Typical Applications

Thanks to its excellent mechanical properties, 45CrNiMoVA alloy steel round bar is widely used in:

-

Heavy-duty shafts and spindles

-

Large gears and gear shafts

-

Mining and construction machinery parts

-

Forging dies and molds

-

Hydraulic cylinders and piston rods

-

Pressure vessel components

-

Power transmission and drive systems

It is especially suitable for components subjected to high load, impact, torsion, and cyclic stress.

Quality Standards and Inspection

Our products can be supplied in accordance with major international standards or customized specifications:

-

GB / ASTM / EN / DIN (upon request)

-

Chemical composition analysis

-

Mechanical property testing

-

Ultrasonic testing (EN 10228, ASTM A388)

-

Dimensional and surface inspection

-

Material test certificate (MTC EN 10204 3.1 / 3.2)

Each batch is traceable to ensure consistent quality and full compliance.

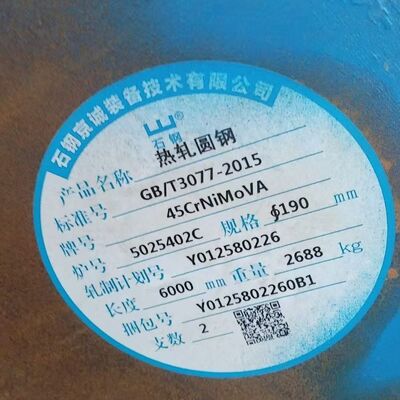

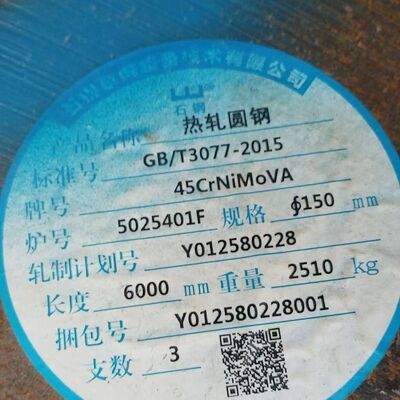

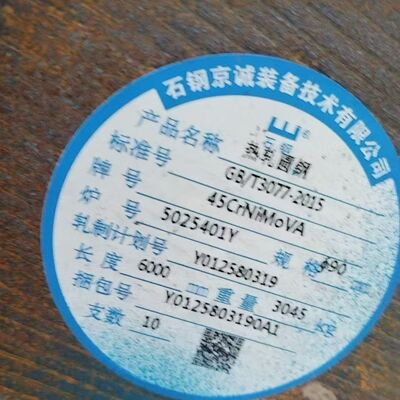

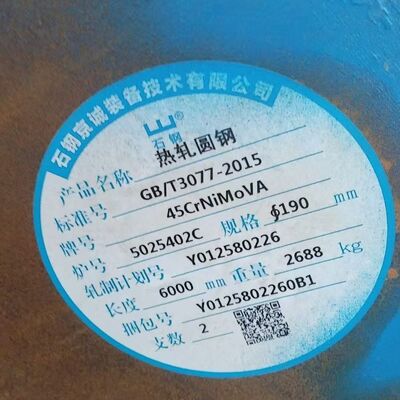

Packaging and Delivery

-

Bundled with steel straps or packed in wooden cases

-

Rust-preventive coating available

-

Clear labeling with heat number and size

-

Flexible logistics for domestic and international delivery

We support bulk orders, project-based supply, and long-term cooperation.

Why Choose Our 45CrNiMoVA Alloy Steel Round Bar?

-

Stable raw material sourcing and advanced production facilities

-

Strict quality control throughout the manufacturing process

-

Competitive pricing for heavy-duty alloy steel products

-

Custom cutting, heat treatment, and inspection services

-

Reliable technical support and fast response

Our goal is to provide high-quality 45CrNiMoVA alloy steel solutions that enhance the performance, safety, and service life of your equipment.

Conclusion

The Hot Rolled 45CrNiMoVA Alloy Steel Round Bar for Heavy-Duty Applications is a reliable and cost-effective solution for demanding industrial environments. With excellent strength, toughness, and wear resistance, combined with custom cutting in length and flexible heat treatment options, it meets the diverse needs of modern engineering projects.

![]()

![]()

![]()

![]()