All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

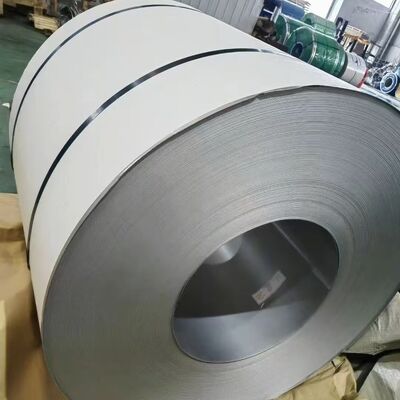

Premium 316H Stainless Steel Plate High-Temperature Resistance & Corrosion Protection

Product Details

| Products | Stainless Steel Plate | Grade | 316H |

|---|---|---|---|

| Thickness | 1.5-50.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | 316H stainless steel plate,high-temperature resistant steel plate,corrosion-resistant stainless steel plate |

||

Product Description

Premium 316H Stainless Steel Plate High-Temperature Resistance & Corrosion Protection

Stainless Steel Plate Specifications

| Name | 316H stainless steel Plate |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

Premium 316H Stainless Steel Plate – High-Temperature Resistance & Corrosion Protection

Overview

Premium 316H stainless steel plate is a high-performance austenitic stainless steel engineered for demanding industrial applications that require exceptional resistance to elevated temperatures and aggressive corrosive environments. With its enhanced carbon content compared to standard 316 stainless steel, 316H offers superior mechanical strength at high operating temperatures—making it the material of choice in sectors such as power generation (especially nuclear and fossil fuel plants), petrochemical processing, aerospace, and marine engineering.

This product information page provides comprehensive technical details, chemical composition, mechanical properties, and application guidance for engineers, procurement specialists, and fabricators seeking reliable, long-lasting materials for critical high-temperature and corrosion-prone systems.

Why Choose 316H Over Standard 316?

While both 316 and 316H belong to the same austenitic stainless steel family, 316H contains a higher carbon content (0.04–0.10%), which significantly improves its creep strength and structural integrity at temperatures above 500°C (932°F). This makes 316H ideal for pressure vessels, heat exchangers, boiler components, and piping systems operating under sustained thermal stress.

Key advantages of 316H include:

- Excellent resistance to oxidation and scaling up to 870°C (1600°F)

- Superior performance in chloride-rich and acidic environments

- Enhanced weldability and post-weld stability without sensitization (when properly processed)

- Compliance with international standards including ASTM A240, ASME SA-240, UNS S31609, and AISI 316H

Chemical Composition (Weight %)

| Element | 316H Stainless Steel (Typical Range) |

|---|---|

| Carbon (C) | 0.04 – 0.10% |

| Manganese (Mn) | ≤ 2.00% |

| Phosphorus (P) | ≤ 0.045% |

| Sulfur (S) | ≤ 0.030% |

| Silicon (Si) | ≤ 0.75% |

| Chromium (Cr) | 16.0 – 18.0% |

| Nickel (Ni) | 10.0 – 14.0% |

| Molybdenum (Mo) | 2.0 – 3.0% |

| Iron (Fe) | Balance |

Note: The controlled carbon range ensures optimal high-temperature strength while minimizing carbide precipitation during welding—critical for maintaining corrosion resistance in welded structures.

Mechanical Properties (Room Temperature)

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 515 MPa (75,000 psi) |

| Yield Strength (0.2% offset) | ≥ 205 MPa (30,000 psi) |

| Elongation | ≥ 40% (in 50 mm) |

| Hardness (Rockwell B) | ≤ 95 HRB |

| Density | 8.0 g/cm³ |

| Melting Point | 1375–1400°C (2500–2550°F) |

These values meet or exceed ASTM A240 specifications for pressure vessel and high-temperature service applications.

High-Temperature Performance

316H excels where standard stainless steels fail. Its elevated carbon content stabilizes the microstructure under prolonged thermal exposure, reducing creep deformation and maintaining load-bearing capacity.

Short-Term Oxidation Resistance

- Continuous service up to 870°C (1600°F) in oxidizing atmospheres

- Intermittent service up to 925°C (1700°F)

Creep & Rupture Strength (Approximate)

| Temperature (°C) | 10,000-Hour Rupture Strength (MPa) |

|---|---|

| 600 | ~80 MPa |

| 650 | ~55 MPa |

| 700 | ~35 MPa |

| 750 | ~20 MPa |

Data based on ASME Section II, Part D. Actual performance may vary with fabrication method and service conditions.

Corrosion Resistance

Thanks to its molybdenum (2–3%) and chromium (16–18%) content, 316H offers outstanding resistance to:

- Pitting and crevice corrosion in chloride environments (e.g., seawater, coastal installations)

- Sulfuric, acetic, and formic acids

- Organic and fatty acids commonly found in food and pharmaceutical processing

- Industrial pollutants and exhaust gases

It outperforms 304/304L in marine and chemical settings and is often specified where long-term durability in harsh media is non-negotiable.

Common Applications

| Industry | Application Examples |

|---|---|

| Power Generation | Superheater tubes, steam headers, reactor internals (sodium-cooled fast reactors) |

| Petrochemical | Distillation columns, heat exchangers, acid storage tanks |

| Marine | Offshore platform components, desalination plants |

| Aerospace | Jet engine parts, exhaust manifolds |

| Pharmaceutical/Food | High-purity processing equipment requiring sterilization and corrosion resistance |

| Waste Incineration | Flue gas ducts, combustion chambers |

Fabrication & Welding Guidelines

316H can be readily formed, machined, and welded using standard techniques:

- Welding: Use low heat input and matching filler metals (e.g., ER316H or ER316L for thin sections). Post-weld annealing is generally not required but may be used to restore full corrosion resistance in severe environments.

- Machining: Slower speeds and rigid setups recommended due to work hardening tendency.

- Forming: Excellent ductility allows cold forming; annealing may be needed after severe deformation.

- Heat Treatment: Solution anneal at 1040–1150°C (1900–2100°F) followed by rapid quenching (water or air).

Standards & Certifications

Our Premium 316H Stainless Steel Plates comply with the following global standards:

- ASTM A240/A240M – Standard specification for chromium and chromium-nickel stainless steel plate

- ASME SA-240 – For pressure vessel applications

- UNS S31609 – Unified Numbering System designation

- EN 10088-2: X2CrNiMo17-12-2 (European equivalent, with adjusted C content)

- ISO 15510: International material standard

All plates are supplied with Mill Test Reports (MTRs) per EN 10204 3.1, including chemical analysis and mechanical test results.

Available Dimensions & Finishes

| Parameter | Options |

|---|---|

| Thickness | 3 mm to 150 mm (0.12" to 6") |

| Width | Up to 3000 mm (118") |

| Length | Up to 12,000 mm (472") |

| Surface Finish | 2B, BA (Bright Annealed), No. 1, No. 4 (Brushed), 2D, Pickled & Annealed |

| Edge Condition | Mill edge, slit edge, or sheared |

| Packaging | Waterproof wrapping, wooden pallets, export-ready |

Custom cutting (plasma, laser, waterjet) and machining services available upon request.

Quality Assurance & Traceability

Every batch of our 316H stainless steel plate undergoes rigorous quality control:

- Spectrometric chemical analysis

- Ultrasonic testing (UT) for internal defects (optional per customer requirement)

- Tensile and hardness testing

- Full lot traceability from melt to delivery

We maintain ISO 9001:2015 certification and adhere to strict environmental and safety protocols throughout production.

Why Source from Us?

- Global Supply Network: Fast delivery to North America, Europe, Middle East, and Asia

- Technical Support: In-house metallurgists provide application-specific advice

- Competitive Pricing: Direct mill relationships ensure cost efficiency without compromising quality

- Sustainability: Recyclable material with low lifecycle environmental impact

FAQs

Q: Is 316H suitable for cryogenic applications?

A: Yes—its austenitic structure remains ductile down to -196°C (-320°F), though 304L or 316L are more common for such uses due to lower carbon.

A: Yes—its austenitic structure remains ductile down to -196°C (-320°F), though 304L or 316L are more common for such uses due to lower carbon.

Q: Can 316H be used in seawater?

A: With caution. While better than 304, prolonged seawater exposure may still cause pitting. Consider super austenitic (e.g., 904L) or duplex grades for critical marine use.

A: With caution. While better than 304, prolonged seawater exposure may still cause pitting. Consider super austenitic (e.g., 904L) or duplex grades for critical marine use.

Q: What’s the difference between 316H and 316Ti?

A: 316Ti uses titanium stabilization to prevent sensitization; 316H relies on controlled carbon for high-temp strength. Choose 316H for creep resistance, 316Ti for welded high-temp corrosion service.

A: 316Ti uses titanium stabilization to prevent sensitization; 316H relies on controlled carbon for high-temp strength. Choose 316H for creep resistance, 316Ti for welded high-temp corrosion service.

Contact Us Today

For technical datasheets, sample requests, or bulk quotations on Premium 316H Stainless Steel Plate, contact our sales team. We support OEMs, EPC contractors, and fabricators worldwide with certified, high-integrity materials built for extreme environments.

Recommended Products