-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

2507 (UNS S32750) Super Duplex Stainless Steel Sheet/Plate for Severe Environments in Oil, Gas, and Marine Industries

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL TISCO |

| Certification | ISO |

| Model Number | S32750 / 2507 |

| Minimum Order Quantity | 50 kgs |

| Price | 5 - 8 USD/Kg |

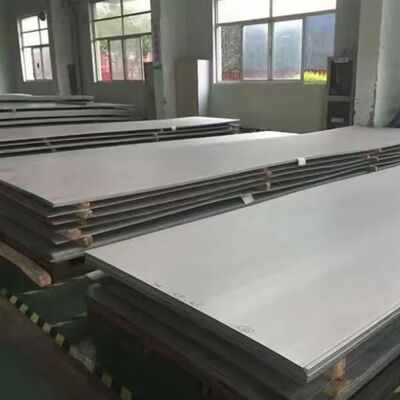

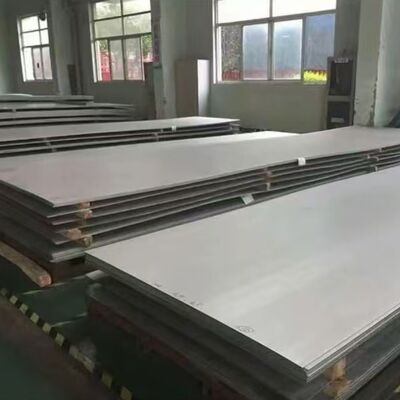

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Duplex Stainless Steel Sheet | Grade | 2507 / S32750 |

|---|---|---|---|

| Thickness | 1.0 - 30.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | Super Duplex Stainless Steel Sheet,2507 stainless steel plate for oil industry,S32750 marine grade steel sheet |

||

2507 (UNS S32750) Super Duplex Stainless Steel Sheet/Plate for Severe Environments in Oil, Gas, and Marine Industries

Stainless Steel Sheet Specifications

| Name | Duplex stainless steel sheet |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Duplex: 2205 2507 2304 2101 2550 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

Regular Size of Our Duplex Stainless Steel Sheet in Stock

| Grade | Thickness | Size | Surface | Actual Thickness |

| 2507 | 1.0mm | 1219*2438mm | 2B | 0.92 |

| 2507 | 1.2mm | 1219*2438mm | 2B | 1.12 |

| 2507 | 1.5mm | 1219*2438mm | 2B | 1.45 |

| 2507 | 2.0mm | 1219*2438mm | 2B | 1.91 |

| 2507 | 2.5mm | 1219*2438mm | 2B | 2.38 |

| 2507 | 3.0mm | 1219*2438mm | 2B | 2.88 |

| 2507 | 4.0mm | 1500*6000mm | NO.1 | 3.85 |

| 2507 | 5.0mm | 1500*6000mm | NO.1 | 4.75 |

| 2507 | 6.0mm | 1500*6000mm | NO.1 | 5.75 |

| 2507 | 8.0mm | 1500*6000mm | NO.1 | 7.75 |

| 2507 | 10.0mm | 1500*6000mm | NO.1 | 9.75 |

| 2507 | 12.0mm | 1500*6000mm | NO.1 | 11.5-11.75 |

| 2507 | 14.0mm | 1500*6000mm | NO.1 | 13.75 |

| 2507 |

16.0mm |

1500*6000mm | NO.1 | 15.5-15.75 |

| 2507 | 20.0mm | 1500*6000mm | NO.1 | 19.5-20 |

| 2507 | 25.0mm | 1500*6000mm | NO.1 | 24.5-25 |

| 2507 | 30.0mm | 1500*6000mm | NO.1 | 29.5-30 |

2507 (UNS S32750) Super Duplex Stainless Steel Sheet/Plate – Engineered for Severe Environments in Oil, Gas, and Marine Industries

Product Overview

When operating in the world’s most aggressive industrial environments—where high chloride concentrations, sour gases (H₂S), elevated temperatures, and seawater exposure threaten structural integrity—2507 (UNS S32750) Super Duplex Stainless Steel stands as the material of choice for mission-critical applications.

Our premium-grade 2507 stainless steel sheets and plates are specifically engineered to deliver exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC), combined with high mechanical strength and long-term reliability. Compliant with ASTM A240/A240M, NACE MR0175/ISO 15156, and EN 10088-2, these products are trusted across the oil & gas, offshore, subsea, and marine sectors for components that cannot afford failure.

Available in thicknesses from 1.0 mm to 30.0 mm and standard or custom dimensions, our 2507 inventory supports rapid fabrication, global project compliance, and decades of service life—even under extreme conditions.

Why 2507 Super Duplex for Oil, Gas & Marine?

| Challenge | 2507 Solution |

|---|---|

| Seawater exposure | Resists biofouling, pitting, and crevice corrosion up to 70°C |

| Sour service (H₂S) | Certified per NACE MR0175 for use in oil & gas wells |

| High chloride content | PREN ≥ 40 prevents localized corrosion where 316L fails |

| High pressure & temperature | Yield strength >550 MPa enables thinner, lighter designs |

| Subsea installations | Proven performance in manifolds, risers, and Christmas trees |

Unlike standard austenitic steels, 2507 maintains integrity in dynamic, corrosive, and high-stress environments—reducing maintenance, downtime, and lifecycle costs.

Technical Specifications

Chemical Composition (Typical – wt%, per ASTM A240)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 24.0–26.0 |

| Nickel (Ni) | 6.0–8.0 |

| Molybdenum (Mo) | 3.0–5.0 |

| Nitrogen (N) | 0.24–0.32 |

| Carbon (C) | ≤0.030 |

| Manganese (Mn) | ≤1.20 |

| Silicon (Si) | ≤0.80 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.020 |

| Iron (Fe) | Balance |

PREN (Pitting Resistance Equivalent Number) = %Cr + 3.3×%Mo + 16×%N ≥ 40

Mechanical Properties (Solution Annealed)

| Property | Value |

|---|---|

| Tensile Strength | 800–1000 MPa |

| Yield Strength (0.2% offset) | ≥550 MPa |

| Elongation | ≥25% |

| Hardness | ≤290 HB |

| Density | 7.8 g/cm³ |

| Thermal Conductivity | ~30 W/m·K |

Note: Strength is ~2x that of 316L stainless steel.

Corrosion Resistance Performance

| Environment | Performance |

|---|---|

| Natural seawater | Excellent; widely used in offshore platforms, desalination plants |

| 6% FeCl₃ solution | Critical Pitting Temperature (CPT) ≥ 70°C |

| Sour gas (H₂S partial pressure ≤ 0.3 bar) | Approved per NACE MR0175 |

| Brine & produced water | Resists chloride-induced SCC up to 100,000 ppm Cl⁻ |

| Acidic media (e.g., sulfuric, acetic) | Good resistance in moderate concentrations |

This makes 2507 ideal for subsea control modules, downhole safety valves, heat exchangers, and seawater cooling systems.

Available Product Forms & Sizes

| Parameter | Details |

|---|---|

| Material Grade | UNS S32750 / Alloy 2507 / SAF 2507 / W.Nr 1.4410 |

| Form | Hot-rolled plate (≥4 mm), Cold-rolled sheet (<4 mm) |

| Thickness Range | 1.0 mm – 30.0 mm |

| Standard Sizes | • 1000 × 2000 mm • 1219 × 2438 mm (4' × 8') • 1500 × 6000 mm • Custom sizes available |

| Surface Finishes | No.1, 2B, BA, No.4, 2D, pickled, or as specified |

| Certifications | Mill Test Report (EN 10204 3.1/3.2), PMI, UT, NACE, ISO 9001 |

All materials are batch-traceable and stored to prevent surface contamination.

Key Applications in Oil, Gas & Marine

| Industry | Component Examples |

|---|---|

| Offshore Oil & Gas | Subsea manifolds, flowlines, risers, wellheads, separators |

| Onshore Processing | Sour gas scrubbers, amine units, sulfur recovery units |

| LNG & FPSO | Cryogenic piping supports, ballast systems, utility skids |

| Marine & Shipbuilding | Seawater piping, fire mains, condenser tubes, thruster housings |

| Desalination | High-pressure RO membranes, brine heaters, evaporator shells |

Alloy 2507 is often specified when 316L, 2205, or even 904L show premature degradation.

Fabrication Guidelines

- Welding: Use matching filler (e.g., ER2594). Maintain interpass temperature <100°C. Shielding gas: Ar + 2–3% N₂.

- Cutting: Laser, plasma, or waterjet recommended for precision.

- Machining: Use carbide tools, low speeds, high coolant flow.

- Forming: Cold bending radius ≥2× thickness. Avoid prolonged exposure to 280–900°C to prevent embrittlement.

- Post-Weld Treatment: Pickling and passivation restore corrosion resistance.

Quality Assurance

Every shipment includes:

- Full chemical and mechanical test reports

- Positive Material Identification (PMI) verification

- Optional ultrasonic testing (UT) for critical applications

- Compliance with ASTM, ASME, EN, ISO, and NACE standards

We source from certified mills in Europe and Asia, ensuring consistent microstructure and performance.

Sustainability & Lifecycle Advantage

While the initial cost of 2507 is higher than standard stainless steels, its extended service life, minimal maintenance, and resistance to catastrophic failure deliver superior total cost of ownership (TCO)—especially in remote or inaccessible installations like deepwater platforms.

Additionally, stainless steel is 100% recyclable, supporting ESG and net-zero initiatives.

Order & Support

- MOQ: 1 piece (cut-to-size); 500 kg (mill order)

- Lead Time: 3–7 days (stock); 4–6 weeks (mill production)

- Services: CAD-based nesting, laser cutting, edge prep, export packaging

- Global Delivery: FOB, CIF, or DDP terms available

Contact our technical sales team for a free material selection consultation, sample, or project-specific quote.

Conclusion

In the unforgiving worlds of offshore oil extraction, sour gas processing, and marine engineering, compromise is not an option. 2507 (UNS S32750) Super Duplex Stainless Steel Sheet and Plate provides the corrosion immunity, structural strength, and regulatory compliance needed to ensure safety, efficiency, and longevity—even in the most severe environments on Earth.

2507 super duplex stainless steel plate for oil and gas, UNS S32750 sheet marine grade, Alloy 2507 for offshore applications, high corrosion resistant duplex steel, NACE compliant 2507 plate, seawater resistant stainless steel sheet, super duplex 1.4410 for subsea, ASTM A240 S32750 plate supplier, 2507 stainless steel for sour service, duplex steel for severe environments.

![]()

![]()

![]()

![]()