-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

UNS N06625 Nickel Alloy Steel Strip – Ideal for Marine, Nuclear, and Oil & Gas Applications

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 600,625,718,800,c276,400.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 22 - 30 USD/Kg |

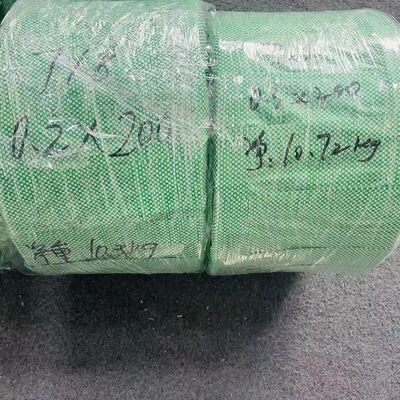

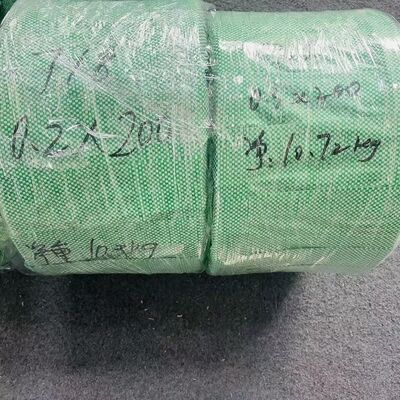

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Alloy Sheet & Plate | Grade | 600,625,718,800,c276,400.etc |

|---|---|---|---|

| Thickness | 0.05 - 30.0mm | Width | Custom Slit Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B BA |

| Highlight | UNS N06625 nickel alloy strip,marine grade nickel alloy strip,oil & gas nickel alloy strip |

||

UNS N06625 Nickel Alloy Steel Strip – Ideal for Marine, Nuclear, and Oil & Gas Applications

Products Specification

| Products Name | UNS N06625 Nickel Alloy Strips |

| Thickness | 0.05 - 3.0mm |

| Width | within 1219mm |

| Surface | 2B BA |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Main Grade | Hastelloy C22 C4 X C276 G35 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 617 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

UNS N06625 Nickel Alloy Steel Strip – Ideal for Marine, Nuclear, and Oil & Gas Applications

Product Overview

UNS N06625, commercially known as Inconel® 625, is a high-performance nickel-chromium-molybdenum-niobium alloy engineered to withstand the most aggressive environments on Earth—and beyond. While often referred to as a “nickel alloy steel strip” in industrial contexts, it is technically a non-ferrous superalloy with exceptional resistance to corrosion, oxidation, and mechanical degradation across extreme temperature ranges (–253°C to 982°C / –423°F to 1800°F).

This precision-engineered UNS N06625 strip is specifically optimized for mission-critical applications in the marine, nuclear, and oil & gas industries, where exposure to seawater, sour gases, radiation, and high-pressure/temperature conditions demands materials of uncompromising reliability.

Why UNS N06625 Excels in Harsh Industrial Environments

The alloy’s outstanding performance stems from its unique composition and microstructure:

- Chromium (20–23%): Forms a stable, self-healing Cr₂O₃ oxide layer for oxidation and corrosion resistance.

- Molybdenum (8–10%): Provides exceptional resistance to pitting and crevice corrosion—especially in chloride-rich seawater.

- Niobium (3.15–4.15%): Stabilizes the alloy against sensitization during welding and enables solid-solution strengthening without heat treatment.

- High Nickel Base (>58%): Ensures ductility, toughness, and structural integrity under thermal cycling and irradiation.

Unlike standard stainless steels (e.g., 316L), which suffer rapid failure in seawater or H₂S environments, Inconel 625 maintains integrity for decades—even in stagnant, oxygen-depleted zones prone to microbiologically influenced corrosion (MIC).

Key Advantages by Industry

Marine Applications

- Resists seawater corrosion, biofouling, and erosion-corrosion in propeller shafts, piping, and heat exchangers.

- Immune to chloride-induced stress corrosion cracking (SCC)—a common failure mode for duplex and austenitic steels.

- Used in submarine hull fittings, offshore platform risers, and desalination plants.

Oil & Gas (Including Sour Service)

- Fully compliant with NACE MR0175/ISO 15156 for use in H₂S-containing (“sour”) environments.

- Resists sulfide stress cracking (SSC) and general corrosion in downhole tools, wellhead components, and flowlines.

- Ideal for deepwater drilling, LNG processing, and refinery alkylation units.

Chemical Composition (UNS N06625 – ASTM B443 / AMS 5599)

| Element | Content (wt.%) |

|---|---|

| Nickel (Ni) | Balance (>58%) |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb+Ta) | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

| Cobalt (Co) | ≤ 1.0 (≤0.05% for nuclear grade) |

All values meet or exceed ASTM, ASME, ISO, and NACE requirements.

Mechanical Properties (Annealed Condition)

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 830 MPa (120 ksi) |

| Yield Strength (0.2% offset) | ≥ 415 MPa (60 ksi) |

| Elongation | ≥ 30% |

| Hardness | ≤ 220 HB |

| Density | 8.44 g/cm³ |

Cold-worked tempers (½-hard, full-hard) offer higher strength for spring or sealing applications.

Precision Strip Specifications

| Parameter | Range |

|---|---|

| Thickness | 0.025 mm – 3.0 mm |

| Width | 5 mm – 610 mm (custom slitting available) |

| Temper | Annealed, ¼-Hard, ½-Hard, Full-Hard, Spring Temper |

| Surface Finish | 2B, Bright Annealed (BA), Matte, Brushed |

| Tolerance | ±0.005 mm (precision grade) |

| Packaging | VCI-wrapped coils in sealed containers for marine transport |

Ideal for stamping, laser cutting, EDM, and automated assembly lines.

Standards & Certifications

| Standard | Designation |

|---|---|

| UNS | N06625 |

| ASTM | B443, B572, B704 |

| ASME | SB-443 |

| AMS | 5599, 5666 |

| DIN / EN | 2.4856 (NiCr22Mo9Nb) |

| ISO | NW 6625 |

| JIS | NCF 625 |

| NACE | MR0175/ISO 15156 Compliant (for sour service) |

| Nuclear Grade | ASTM B704 (low-Co variant) |

Full EN 10204 3.1 or 3.2 certification with traceable mill test reports.

Real-World Applications

| Industry | Component Examples |

|---|---|

| Marine | Seawater heat exchanger plates, sonar domes, thruster bearings, ballast system valves |

| Nuclear | Fuel rod spacers, instrumentation thimbles, steam generator tubesheets, containment penetrations |

| Oil & Gas | Downhole safety valves, Christmas tree components, subsea manifolds, sour gas compressor blades |

These components often operate 24/7 for 20+ years without replacement—testament to Inconel 625’s durability.

Quality Assurance

Every coil undergoes:

- Spectrometric chemistry verification

- Tensile and hardness testing per ASTM E8/E18

- Ultrasonic or eddy current inspection for laminations/inclusions

- Intergranular corrosion testing (ASTM G28)

- Optional: Hydrostatic or dye-penetrant testing for critical parts

Manufacturing facilities are certified to ISO 9001, AS9100, and NQA-1 (nuclear quality assurance) where applicable.

Ordering Guidance

To ensure optimal material selection, provide:

- Grade: UNS N06625 (specify “nuclear grade” if low Co required)

- Form: Cold-rolled precision strip

- Dimensions: Thickness × Width × Length or coil weight

- Temper & Finish: e.g., “½-Hard, Bright Annealed, 0.3 mm × 200 mm”

- Standard: e.g., “Per ASTM B443, NACE MR0175 compliant”

- Certification Level: e.g., “EN 10204 3.2 with full chemistry and mechanicals”

Lead time: 3–8 weeks, depending on specification complexity.

Conclusion

The UNS N06625 nickel alloy strip is not just a material—it’s an engineering safeguard for industries where failure is not an option. Its unparalleled resistance to seawater corrosion, radiation stability, and immunity to sour gas degradation make it the material of record for marine, nuclear, and oil & gas applications worldwide. By choosing certified Inconel 625 strip, operators ensure safety, regulatory compliance, and lifecycle cost savings in the planet’s most unforgiving environments.

UNS N06625 nickel alloy strip, Inconel 625 for marine applications, nuclear-grade Inconel 625 tape, oil and gas corrosion-resistant strip, NACE MR0175 compliant nickel alloy, ASTM B443 sour service strip, DIN 2.4856 seawater-resistant foil, low-cobalt Inconel 625 for nuclear, chloride SCC resistant alloy tape, offshore platform Inconel strip.

![]()

![]()

![]()

![]()