-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

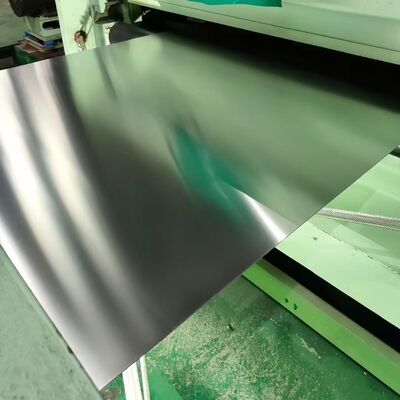

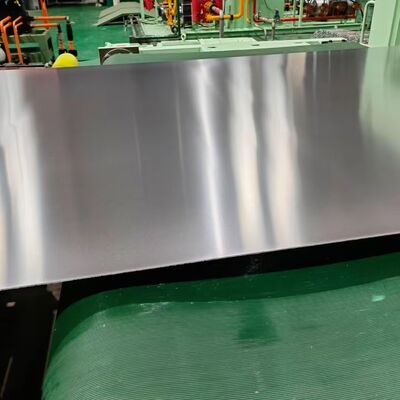

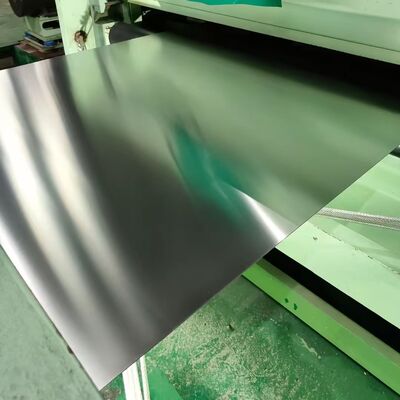

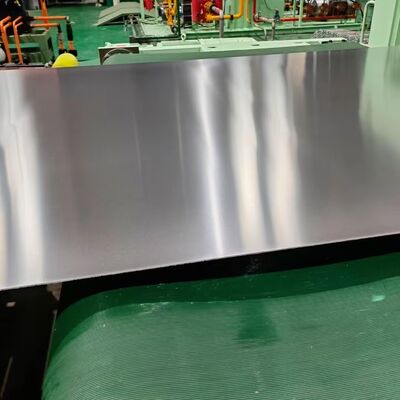

310S Heat Resistant Stainless Steel Sheet and Plate Cold Rolled 4*8ft SS Sheet 1.4845

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Sheet | Grade | 310S |

|---|---|---|---|

| Thickness | 0.6 - 16.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B BA NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | 310S stainless steel sheet heat resistant,cold rolled stainless steel plate 4x8ft,1.4845 stainless steel sheet with warranty |

||

310S Heat Resistant Stainless Steel Sheet and Plate Cold Rolled 4*8ft SS Sheet 1.4845

Stainless Steel Sheet Specifications

| Name | 310S stainless steel sheet |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

310S Heat Resistant Stainless Steel Sheet and Plate – Cold Rolled, 4×8 ft (Grade 1.4845 / UNS S31008)

Overview

310S stainless steel (also designated as UNS S31008 and EN 1.4845) is a high-alloy austenitic stainless steel renowned for its exceptional resistance to oxidation and corrosion at elevated temperatures. Specifically engineered for extreme thermal environments, 310S contains high levels of chromium (24–26%) and nickel (19–22%), which provide outstanding stability and mechanical strength up to 1150°C (2100°F). The "S" in 310S denotes a lower carbon content (<0.08%) compared to standard 310, enhancing weldability and reducing the risk of carbide precipitation during high-temperature service—making it ideal for continuous exposure in oxidizing atmospheres.

This product offering features cold-rolled 310S stainless steel sheets and plates, precision manufactured to exacting tolerances and supplied in the widely used 4 feet by 8 feet (1219 mm × 2438 mm) dimensions. Cold rolling imparts superior surface finish, dimensional accuracy, and enhanced mechanical properties compared to hot-rolled alternatives, making it particularly suitable for applications demanding aesthetic quality, tight tolerances, and consistent performance.

Key Features & Advantages

-

Exceptional High-Temperature Performance: 310S maintains structural integrity and resists scaling in continuous service up to 1035°C (1900°F) and intermittent service up to 1095°C (2000°F). Its high chromium and nickel content form a stable, self-healing oxide layer that protects against oxidation, sulfidation, and carburization.

-

Superior Corrosion Resistance: In addition to thermal resilience, 310S offers excellent resistance to aqueous corrosion, including moderately aggressive organic and inorganic acids, especially in high-temperature environments where other stainless grades would fail.

-

Low Carbon Content for Weldability: With a maximum carbon content of 0.08%, 310S minimizes sensitization during welding, preventing intergranular corrosion in the heat-affected zone (HAZ). This makes it highly suitable for welded fabrications without requiring post-weld heat treatment.

-

Cold-Rolled Precision: The cold-rolling process refines grain structure, improves surface smoothness (typically 2B or BA finish unless specified), and increases tensile and yield strength through strain hardening. Thickness tolerances are held to ±0.05 mm or better, ensuring consistency for precision engineering.

-

Standardized Dimensions: Supplied in 4×8 ft (1219×2438 mm) sheets—a globally recognized size that optimizes material utilization in fabrication, reduces waste, and simplifies logistics across industries such as furnace manufacturing, petrochemical processing, and aerospace.

-

Material Compliance: Fully compliant with international standards including ASTM A240/A240M, ASME SA-240, EN 10088-2 (1.4845), and ISO 15510. Material test reports (MTRs) available upon request, certifying chemical composition and mechanical properties.

Chemical Composition (Typical, wt%)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 24.0–26.0 |

| Nickel (Ni) | 19.0–22.0 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.5 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

This composition ensures optimal balance between high-temperature strength, ductility, and resistance to embrittlement.

Mechanical Properties (Typical, Annealed Condition)

- Tensile Strength: ≥ 515 MPa (75 ksi)

- Yield Strength (0.2% offset): ≥ 205 MPa (30 ksi)

- Elongation: ≥ 40% in 50 mm

- Hardness: ≤ 217 HB

Cold rolling may increase these values depending on the degree of reduction, allowing for tailored mechanical performance.

Common Applications

310S cold-rolled stainless steel sheets and plates are indispensable in industries where materials face prolonged exposure to extreme heat and corrosive atmospheres:

- Thermal Processing Equipment: Radiant tubes, muffles, retorts, kiln linings, and sintering trays in heat-treatment furnaces.

- Petrochemical & Chemical Processing: Catalyst support grids, reformer tubes, and ethylene production components exposed to high-temperature hydrocarbons.

- Power Generation: Boiler baffles, superheater components, and exhaust systems in biomass and waste-to-energy plants.

- Aerospace & Automotive: Exhaust manifolds, afterburners, and thermal barriers requiring lightweight, high-strength alloys.

- Glass & Ceramics Manufacturing: Handling fixtures, rollers, and molds subjected to repeated thermal cycling.

- Welded Fabrications: Ducting, expansion joints, and containment vessels where post-weld integrity is critical.

Fabrication & Machining Considerations

While 310S is readily formable and weldable, its high work-hardening rate requires attention during machining:

- Forming: Best performed in the annealed condition using robust tooling. Springback is moderate; overbending may be necessary.

- Welding: All standard fusion and resistance welding methods are suitable (TIG, MIG, SMAW). Use matching 310 or 312 filler metals. Preheating is unnecessary; interpass temperature should be kept below 150°C.

- Machining: Due to rapid work hardening, use slow speeds, heavy feeds, sharp tools, and ample coolant. Carbide tooling is recommended.

- Heat Treatment: Solution annealing at 1040–1150°C followed by rapid quenching restores optimal corrosion resistance and ductility.

Surface Finishes Available

- 2B Finish: Standard cold-rolled, smooth matte surface—ideal for industrial applications.

- BA (Bright Annealed): Reflective, mirror-like finish achieved under controlled atmosphere—used in decorative or cleanroom settings.

- No. 4 Brushed: Uniform linear grain for architectural or aesthetic purposes (optional).

- Custom finishes (e.g., embossed, polished) available upon request.

Packaging & Delivery

Sheets are carefully packaged with protective film or VCI paper to prevent surface damage during transit. Bundled securely on wooden pallets with edge protection, suitable for export. Full traceability via heat numbers and compliance documentation ensures quality assurance from mill to end-user.

Why Choose 310S Cold-Rolled Sheets?

In demanding high-temperature environments, material failure is not an option. 310S stainless steel delivers unmatched reliability, longevity, and safety. Its cold-rolled form combines the alloy’s innate thermal resilience with the precision and surface quality required by modern engineering. Whether you’re designing a next-generation industrial furnace or maintaining critical refinery infrastructure, 310S (1.4845) cold-rolled sheets in 4×8 ft dimensions offer the perfect blend of performance, availability, and cost-efficiency.

![]()

![]()

![]()

![]()