-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

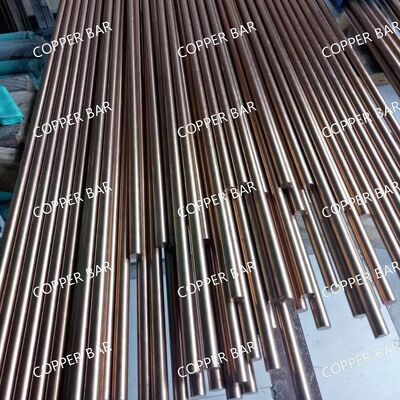

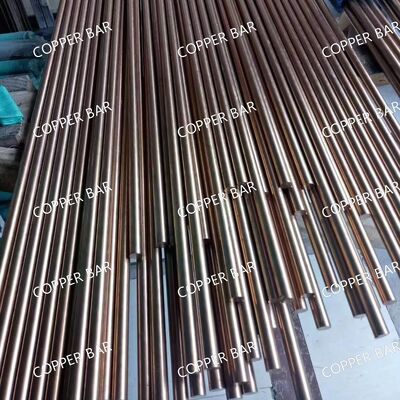

High-Purity C11000 Electrolytic Tough Pitch (ETP) Copper Rod ASTM B187 Compliant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | Pure Copper Bar | Diameter | 4 - 200mm |

|---|---|---|---|

| Length | Custom Any Length As Request | Standard | GB ASTM EN DIN |

| Loading Port | Shanghai Port | Shape | Round |

| Service | Cutting | Company Type | Factory |

| Other Material | Brass | Packing | Wooden Box |

| Highlight | High-Purity C11000 Copper Rod,ETP Copper Rod ASTM B187,Copper Round Bar with Warranty |

||

High-Purity C11000 Electrolytic Tough Pitch (ETP) Copper Rod ASTM B187 Compliant

Specification of our copper products

| Product Name | Pure Copper Bar |

| Material | Copper |

| Standard | ASTM, AISI, JIS, DIN, GB, EN |

| Grade |

C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,C10930, C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,C12500,C14200, C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000, C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800, C63020,C65500,C68700,C70400, C70620,C71000,C71500,C71520,C71640,C72200 T1,T2,T3,TU1,TU0,TU2,TP1,TP2,TAg0.1, |

| Shape | Round |

| Temper | O-H112; T3-T8; T351-T851 |

| Diameter | 4 - 300mm |

| Length | custom cutting any length as request |

| Payment terms | T/T,L/C,western union |

| Price terms | CFR,FOB,CIF,Ex-work,CNF |

| Package | Standard export seaworthy package or as required. |

| Contact | If you have any question,please feel free to contact me. |

High-Purity C11000 Electrolytic Tough Pitch (ETP) Copper Rod – ASTM B187 Compliant

Overview

High-purity C11000 Electrolytic Tough Pitch (ETP) Copper Rod, compliant with ASTM B187, is a premium-grade industrial copper product engineered for applications demanding exceptional electrical conductivity, thermal performance, and mechanical reliability. As one of the most widely used pure copper materials globally, C11000 ETP copper rod serves as a foundational component in electrical engineering, renewable energy systems, building infrastructure, heat exchangers, and advanced scientific instrumentation.

Manufactured from electrolytically refined copper, this rod meets stringent international standards and offers a balanced combination of ductility, strength, and corrosion resistance—making it ideal for both high-volume industrial use and precision-critical applications.

Key Features & Benefits

- Ultra-High Purity: Minimum 99.90% Cu content ensures optimal conductivity.

- Controlled Oxygen Content: 0.02–0.04% oxygen enhances hot workability without compromising electrical performance.

- ASTM B187 Certified: Fully compliant with American Society for Testing and Materials specifications for copper bus bars, rods, and shapes.

- Excellent Formability: Suitable for cold drawing, hot extrusion, forging, and machining.

- Superior Conductivity: ≥100% IACS (International Annealed Copper Standard).

- Versatile Applications: From power transmission to architectural design and vacuum technology.

Chemical Composition (Typical)

| Element | Content (wt.%) | Remarks |

|---|---|---|

| Copper (Cu) | ≥99.90 | Base metal; primary conductor |

| Oxygen (O) | 0.02–0.04 | Enhances hot ductility; controlled to avoid hydrogen embrittlement |

| Silver (Ag) | ≤0.005 | May be present as trace impurity |

| Lead (Pb) | ≤0.005 | Harmful to conductivity; strictly limited |

| Iron (Fe) | ≤0.005 | Controlled to prevent oxide inclusions |

| Sulfur (S) | ≤0.003 | Minimized to avoid hot shortness |

| Other Impurities (Total) | ≤0.03 | Includes Bi, Sb, As, Ni, etc., per ASTM limits |

Note: All values conform to ASTM B187 and UNS C11000 specifications.

Physical & Mechanical Properties

| Property | Annealed Condition | Cold-Worked Condition |

|---|---|---|

| Electrical Conductivity | ≥100% IACS | ≥97% IACS |

| Thermal Conductivity (20°C) | ~401 W/(m·K) | ~395 W/(m·K) |

| Density (g/cm³) | 8.89–8.94 | 8.89–8.94 |

| Tensile Strength (MPa) | 200–250 | 300–400 |

| Elongation (%) | ≥45 | 5–10 |

| Hardness (HV) | 40–60 | 80–110 |

| Resistivity (μΩ·cm at 20°C) | ≤1.724 | ≤1.78 |

| Melting Point (°C) | ~1083 | — |

Properties may vary slightly based on final processing (e.g., degree of cold work or annealing cycle).

Manufacturing Process

The production of high-purity C11000 ETP copper rod follows a rigorous, multi-stage process to ensure consistency and performance:

-

Electrolytic Refining:

Crude copper anodes are purified via electrolysis in sulfuric acid baths, yielding cathodes with >99.99% Cu purity. This step removes harmful impurities like arsenic, antimony, and lead. -

Continuous Casting:

Refined copper is melted under controlled atmosphere and cast into billets using vertical or horizontal continuous casting systems. This minimizes segregation and porosity. -

Hot Extrusion or Rolling:

Billets are heated to 700–900°C and extruded or rolled into rod stock. Temperature control prevents grain coarsening and surface oxidation. -

Cold Drawing (Optional):

For higher strength and tighter dimensional tolerances, rods undergo cold drawing at room temperature. This increases tensile strength but reduces ductility. -

Annealing (If Required):

Final annealing at 400–600°C relieves internal stresses, restores ductility, and stabilizes electrical properties—especially critical for wire-drawing or bending operations. -

Quality Inspection:

Each batch undergoes spectrographic analysis, eddy current testing, dimensional checks, and visual inspection to meet ASTM B187 and customer-specific requirements.

Compliance & Standards

Our C11000 ETP copper rod is certified to the following standards:

| Standard | Description |

|---|---|

| ASTM B187 | Standard Specification for Copper Bus Bar, Rod, and Shapes |

| UNS C11000 | Unified Numbering System designation for ETP copper |

| EN 13601 | European standard for copper and copper alloys – rod for electrical purposes |

| GB/T 4423-2007 | Chinese national standard for drawn copper and copper alloy rods |

| IEC 600228 | International standard for conductors of insulated cables (reference conductivity) |

All material comes with a Mill Test Report (MTR) detailing chemical composition, mechanical test results, and compliance documentation.

Common Applications

| Industry | Application Examples |

|---|---|

| Electrical & Power | Busbars, transformer windings, switchgear contacts, grounding rods, cable conductors |

| Renewable Energy | Solar inverter components, EV charging infrastructure, battery interconnects |

| Building & Architecture | Roofing, downspouts, decorative elements, lightning protection systems |

| Thermal Management | Heat sinks, condenser tubes, radiator fins, HVAC components |

| Industrial Machinery | Bearings, bushings, welding electrodes, molds |

| Scientific & High-Tech | Particle accelerator components, cryogenic systems, sputtering targets, vacuum chamber parts |

Thanks to its high purity and consistent microstructure, C11000 ETP copper is also frequently used as feedstock for further processing into wire, strip, or foil.

Processing & Fabrication Guidelines

To maximize performance and avoid defects during fabrication:

- Machining: Use sharp tungsten carbide tools with ample coolant (e.g., soluble oil emulsion). Copper’s high ductility can cause built-up edge; high cutting speeds and low feed rates are recommended.

- Welding: TIG (GTAW) is preferred. Avoid oxy-fuel welding due to risk of porosity from oxygen-hydrogen reactions. Preheat thick sections to 200–300°C if needed.

- Bending/Forming: Annealed rods allow tight radii without cracking. Cold-worked rods should be stress-relieved before severe forming.

- Joining: Soldering and brazing are highly effective. Use phosphorus-containing filler metals for self-fluxing joints in ETP copper.

- Surface Finishing: Can be polished, plated (e.g., tin, silver), or passivated for enhanced corrosion resistance or aesthetics.

Storage & Handling Recommendations

- Store in a dry, low-humidity environment (<60% RH) to prevent oxidation and patina formation.

- Avoid contact with chlorides, ammonia, or acidic vapors, which accelerate corrosion.

- Keep away from carbon steel surfaces to prevent iron contamination (which can reduce conductivity).

- Use non-abrasive packaging (e.g., plastic wrap or VCI paper) for long-term storage.

Why Choose Our C11000 ETP Copper Rod?

- Consistent Quality: Produced in ISO 9001-certified facilities with real-time process monitoring.

- Traceability: Full lot traceability from cathode to finished rod.

- Customization: Available in diameters from 5 mm to 150 mm, lengths up to 6 meters, and tailored tempers (annealed, 1/2 hard, hard).

- Global Supply: Ready for export with full documentation (COO, MSDS, MTR, RoHS/REACH compliance where applicable).

- Technical Support: Our metallurgical team provides application-specific guidance on selection, processing, and troubleshooting.

Frequently Asked Questions (FAQ)

Q: Is C11000 the same as “oxygen-free” copper?

A: No. C11000 is Electrolytic Tough Pitch copper with controlled oxygen (0.02–0.04%). Oxygen-free copper (e.g., C10100 or C10200) contains <0.001% oxygen and is used in high-vacuum or hydrogen-rich environments to prevent steam embrittlement.

Q: Can C11000 be used in marine environments?

A: With caution. While it resists atmospheric corrosion well, prolonged exposure to salt spray can lead to pitting. Protective coatings or alloy alternatives (e.g., naval brass) are recommended for harsh marine use.

Q: What’s the difference between ASTM B187 and ASTM B224?

A: ASTM B187 covers general-purpose copper rod, bar, and shapes, while ASTM B224 focuses specifically on electrolytic tough pitch copper for electrical conductor applications. Both often reference C11000, but B187 includes broader dimensional and mechanical requirements.

Conclusion

High-purity C11000 Electrolytic Tough Pitch Copper Rod compliant with ASTM B187 represents the gold standard in industrial pure copper materials. Its unmatched blend of conductivity, formability, and reliability makes it indispensable across modern industries—from smart grids and electric vehicles to next-generation electronics and sustainable architecture.

As global demand for efficient, clean energy solutions grows, the role of high-conductivity copper like C11000 will only expand. Whether you’re designing a high-efficiency motor or restoring a historic building, our C11000 ETP copper rod delivers performance you can trust—batch after batch.

C11000 copper rod, ETP copper rod, ASTM B187 copper, high-purity copper rod, electrolytic tough pitch copper, copper rod for electrical applications, C11000 properties, copper rod supplier, 99.9% pure copper, copper busbar material, copper rod mechanical properties, C11000 vs C10200, copper rod for transformers, ASTM-compliant copper.

![]()

![]()

![]()

![]()