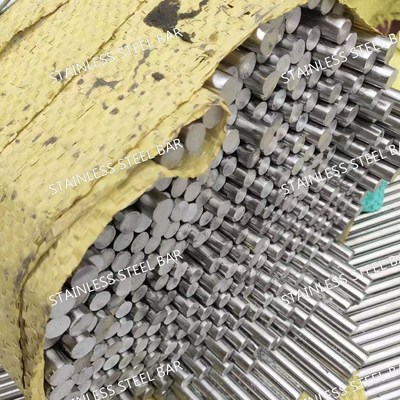

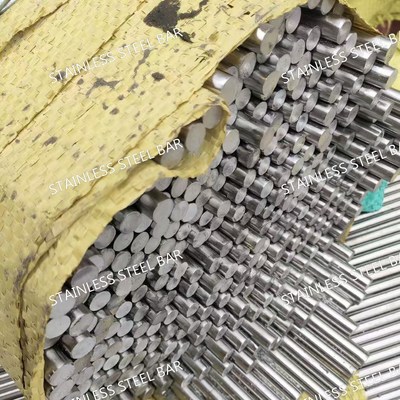

High Precision 303 Stainless Steel Round Bar for Machining Applications

The 303 stainless steel round bar is a premium austenitic stainless steel product designed for demanding machining applications. Known for its excellent machinability, corrosion resistance, and dimensional stability, 303 stainless steel is widely used across precision engineering, automotive components, aerospace fittings, food machinery parts, and general mechanical fabrication.

Engineers choose 303 stainless steel round bars when they need a material that offers the strength of stainless steel but with significantly enhanced cutting and machining efficiency. The addition of sulfur makes 303 one of the most machinable stainless steel grades available, while still maintaining the durability and appearance that stainless steel is known for.

This product page provides detailed specifications, mechanical properties, available sizes, benefits, and typical industrial applications to help you evaluate whether the High Precision 303 Stainless Steel Round Bar is the right choice for your project.

1. Product Overview

The High Precision 303 Stainless Steel Round Bar is manufactured through advanced cold-drawing and centerless-grinding processes to achieve a bright, smooth surface and tight dimensional tolerances. These bars are ideal for CNC machining, turning, drilling, threading, and milling operations without excessive tool wear.

Key Highlights

-

Superior machinability compared to other stainless steels

-

Excellent dimensional accuracy and straightness

-

Good corrosion resistance in mild environments

-

Smooth, bright surface finish

-

Suitable for high-speed production environments

-

Non-magnetic in annealed condition

-

Available in custom lengths and tolerances

2. Chemical Composition of 303 Stainless Steel

303 stainless steel belongs to the AISI 300 series and is enhanced with sulfur to improve machinability. The table below summarizes the typical chemical composition.

Table 1: Chemical Composition (%)

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.15 |

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 8.0 – 10.0 |

| Manganese (Mn) | ≤ 2.0 |

| Sulfur (S) | 0.15 – 0.35 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.20 |

| Iron (Fe) | Balance |

The elevated sulfur content is the primary reason why 303 offers significantly better cutting performance compared to 304 stainless steel.

3. Mechanical Properties

303 stainless steel maintains good strength and toughness across a wide temperature range. The following mechanical properties apply to annealed material.

Table 2: Mechanical Properties

| Property | Metric Value | Imperial Value |

|---|---|---|

| Tensile Strength | 515 – 750 MPa | 75,000 – 109,000 psi |

| Yield Strength | ≥ 205 MPa | ≥ 30,000 psi |

| Elongation | ≥ 35% | ≥ 35% |

| Hardness (Brinell) | 160 – 190 HB | 160 – 190 HB |

| Modulus of Elasticity | 193 GPa | 28 x 10⁶ psi |

These properties make the 303 round bar particularly suitable for medium-to-high strength components that require precision machining.

4. Physical Properties

Table 3: Physical Properties

| Property | Value |

|---|---|

| Density | 7.93 g/cm³ |

| Melting Range | 1400 – 1450°C |

| Thermal Conductivity | 16.3 W/m·K |

| Electrical Resistivity | 0.72 μΩ·m |

| Coefficient of Expansion | 17.3 µm/m°C (0–100°C) |

5. Available Sizes and Tolerances

The High Precision 303 Stainless Steel Round Bar is available in a wide range of diameters and lengths. Custom diameters and tolerances are available upon request.

Table 4: Standard Dimensions

| Diameter Range | Length Options | Surface Type | Tolerances |

|---|---|---|---|

| 3 mm – 200 mm | 1 m, 2 m, 3 m, custom length | Bright, centerless-ground | h8, h9, h11 or custom |

Surface Finish

-

Smooth and bright

-

Meets requirements for high-precision machining

-

Optional polished and mirror-finish versions available

6. Key Features and Advantages

1. Exceptional Machinability

303 stainless steel is known as the most machinable austenitic stainless steel. It supports high feed rates, reduces tool wear, and ensures smooth chip formation, enabling faster machining cycles and reduced production costs.

2. Good Corrosion Resistance

While not as corrosion-resistant as 304, 303 performs well in:

-

Mild atmospheric conditions

-

Food processing environments

-

Light chemical exposure

-

Fresh water

-

Oxidizing environments

3. High Dimensional Accuracy

Our high-precision production ensures:

-

Tight tolerances

-

Uniform diameter

-

Excellent concentricity

-

Minimal surface defects

4. Attractive Appearance

The bright surface finish enhances the aesthetic appeal of finished components, making the material suitable for visible mechanical parts, fittings, and decorative hardware.

5. Stable Mechanical Performance

Even after machining or moderate loads, 303 stainless steel maintains:

-

Consistent strength

-

Toughness

-

Dimensional stability

7. Applications of 303 Stainless Steel Round Bar

Thanks to its machinability and durability, 303 round bars are used across multiple industries.

Common Applications

-

Precision CNC machined parts

-

Shafts, pins, and studs

-

Instrumentation fittings

-

Gears, fasteners, and bushings

-

Valves and pump components

-

Screws, bolts, and nuts

-

Aerospace connectors

-

Automobile precision parts

-

Food machinery parts

-

Marine hardware (non-critical components)

Industries Using 303 Round Bars

-

Automotive

-

Aerospace

-

Machinery manufacturing

-

Electronics

-

Marine equipment

-

Food processing

-

Medical devices (non-implant)

-

Industrial automation

8. Comparison: 303 vs. 304 vs. 316 Stainless Steel

Table 5: Material Comparison

| Property | 303 | 304 | 316 |

|---|---|---|---|

| Machinability | Excellent | Good | Fair |

| Corrosion Resistance | Good | Very Good | Excellent |

| Strength | Moderate–High | High | High |

| Weldability | Fair | Excellent | Excellent |

| Applications | Machining, fittings | General-purpose | High corrosion resistance |

If machinability is your top priority, 303 is the best choice.

If corrosion resistance or weldability is more important, consider 304 or 316.

9. Manufacturing Processes

To achieve high precision and a bright surface, our 303 stainless steel round bars undergo:

-

Hot rolling or hot forging

-

Cold drawing for improved tolerance and finish

-

Centerless grinding for superior surface quality

-

Cutting to custom lengths

-

Final inspection and testing

10. Quality Assurance

Each batch of 303 stainless steel round bar is tested for:

-

Chemical composition

-

Mechanical strength

-

Dimensional accuracy

-

Surface quality

-

Hardness

-

Straightness

Certifications available:

-

EN / ASTM / JIS standards

-

Mill test reports (MTR)

-

RoHS compliance

11. Packaging & Delivery

To ensure the product arrives in perfect condition:

Packaging Options

-

Waterproof plastic wrapping

-

Anti-rust paper

-

Wooden cases or pallets

-

Customized export packaging

Delivery Options

-

Sea freight

-

Air freight

-

Express shipments for urgent orders

12. Why Choose Our High Precision 303 Stainless Steel Round Bars?

-

Consistent, reliable material quality

-

Competitive pricing for bulk orders

-

Fast delivery with stable stock availability

-

Professional technical support

-

Custom machining solutions available

13. Ordering Information

To request a quote, please provide:

-

Required diameter

-

Length

-

Tolerance level

-

Surface finish

-

Quantity

-

Delivery destination

Our technical and sales teams will respond promptly with detailed pricing and lead times.

If you need help extending this to a full landing page, adding metadata, keywords, or schema markup, feel free to ask!