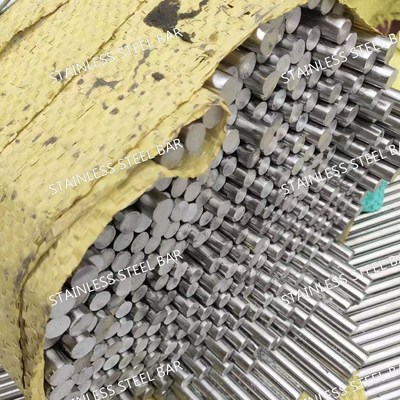

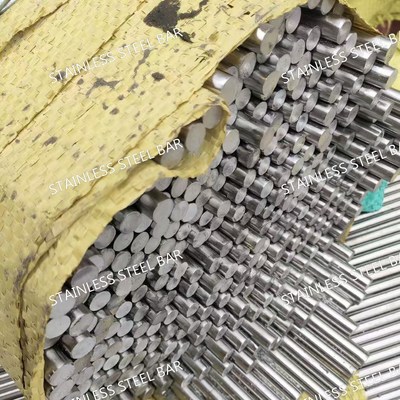

고 정밀 303 스테인리스 스틸 원형 바 가공 응용 프로그램

The303 스테인레스 스틸 원형 막대요구 가공 응용 프로그램에 설계 된 고급 오스테니틱 스테인리스 스틸 제품입니다.우수한 가공성,부식 저항성, 그리고차원 안정성, 303 스테인레스 스틸은 정밀 엔지니어링, 자동차 부품, 항공 우주 피팅, 식품 기계 부품 및 일반적인 기계 제조에 널리 사용됩니다.

엔지니어들은 선택303 스테인레스 스틸 원형 막대그들은 스테인리스 스틸의 강도를 제공하는 물질이 필요하지만 절단 및 가공 효율이 크게 향상됩니다.황 을 첨가 함 으로 인해 303 는 가공 가능 한 스테인레스 스틸 중 가장 가공 가능 한 종류 중 하나 이다, 스테인리스 스틸이 잘 알려진 내구성과 외관을 유지하면서.

이 제품 페이지에는 세부적인 사양, 기계적 특성, 사용 가능한 크기, 이점 및 전형적인 산업용 용도 등이 포함되어 있습니다.고 정밀 303 스테인레스 스틸 원형 막당신의 프로젝트에 맞는 선택입니다.

1제품 개요

The고 정밀 303 스테인레스 스틸 원형 막선진적인 냉면화 및 중심이 없는 썰기 공정을 통해 선명하고 부드러운 표면과 좁은 차원 허용도를 달성합니다. 이 막대는 CNC 가공, 회전,뚫기, 가공 및 가공 작업은 과도한 도구 마모를 방지합니다.

주요 내용

-

다른 스테인레스 스틸에 비해 우수한 가공성

-

우수한 차원 정확성 및 직선성

-

온화한 환경에서의 좋은 부식 저항성

-

부드럽고 밝은 표면

-

고속 생산 환경에 적합

-

소화 상태에서 자기적이지 않은 물질

-

사용자 정의 길이와 허용량으로 제공됩니다.

2303 스테인리스 스틸의 화학적 성분

303 스테인레스 스틸은AISI 300 시리즈그리고 가공성을 향상시키기 위해 황으로 강화됩니다. 아래 표는 전형적인 화학 조성을 요약합니다.

표 1: 화학 성분 (%)

| 원소 | 함유량 (%) |

|---|---|

| 탄소 (C) | ≤ 0.15 |

| 크롬 (Cr) | 17.0 ∙ 190 |

| 니켈 (Ni) | 80.0 100 |

| 망간 (Mn) | ≤ 20 |

| 황 (S) | 00.15 ∼ 0.35 |

| 실리콘 (Si) | ≤ 10 |

| 포스포스 (P) | ≤ 0.20 |

| 철 (Fe) | 재고 |

높은 황 함량은 304 스테인리스 스틸에 비해 303이 훨씬 더 나은 절단 성능을 제공하는 주된 이유입니다.

3기계적 특성

303 스테인레스 스틸은 넓은 온도 범위에서 좋은 강도와 강도를 유지합니다. 다음 기계적 특성은 반열 된 재료에 적용됩니다.

표 2: 기계적 특성

| 재산 | 메트릭 값 | 제국적 가치 |

|---|---|---|

| 팽창 강도 | 515 750 MPa | 75,000 109,000 psi |

| 생산력 | ≥ 205 MPa | ≥ 30,000 psi |

| 길쭉함 | ≥ 35% | ≥ 35% |

| 강도 (Brinell) | 160 ¥ 190 HB | 160 ¥ 190 HB |

| 탄력성 모듈 | 193 GPa | 28 x 106 psi |

이러한 특성으로 303 둥근 막대는 정밀 가공이 필요한 중고 고강성 부품에 특히 적합합니다.

4. 물리적 특성

표 3: 물리적 특성

| 재산 | 가치 |

|---|---|

| 밀도 | 7.93g/cm3 |

| 녹는 범위 | 1400°C ~ 1450°C |

| 열전도성 | 16.3 W/m·K |

| 전기 저항성 | 00.72 μΩ·m |

| 확장 계수 | 17.3μm/m°C (0~100°C) |

5사용 가능한 크기와 허용량

The고 정밀 303 스테인레스 스틸 원형 막넓은 범위의 지름과 길이에서 사용할 수 있습니다. 주문 직경과 허용량은 요청에 따라 제공됩니다.

표 4: 표준 차원

| 지름 범위 | 길이 옵션 | 표면 유형 | 용인 |

|---|---|---|---|

| 3mm 200mm | 1m, 2m, 3m, 맞춤형 길이 | 밝은, 중심이 없는 땅 | h8, h9, h11 또는 사용자 지정 |

표면 마감

-

부드럽고 밝은

-

고 정밀 가공 요구 사항을 충족합니다.

-

선택적으로 닦은 버전과 거울 가공 버전이 제공됩니다.

6주요 특징 및 장점

1특별한 가공성

303 스테인리스 스틸은가장 가공가능한 아우스테니틱 스테인리스 스틸그것은 높은 피드 레이트를 지원하고 도구 마모를 줄이고 부드러운 칩 형성을 보장하여 더 빠른 가공 주기를 가능하게하고 생산 비용을 줄입니다.

2좋은 경식 저항성

304만큼 부식 저항성이 떨어지는 반면,

-

온화한 대기 조건

-

식품 가공 환경

-

가벼운 화학물질 노출

-

민물

-

산화 환경

3고차원 정확성

우리의 고정밀 생산은 다음과 같은 것을 보장합니다.

-

엄격한 허용

-

균일 지름

-

탁월한 동심성

-

최소 표면 결함

4매력적인 외모

밝은 표면 완성품은 완성된 부품의 미적 매력을 향상시켜 가시적인 기계 부품, 피팅 및 장식용 하드웨어에 적합합니다.

5안정적인 기계적 성능

가공 후 또는 중소 로드 후에도, 303 스테인레스 스틸은 유지:

-

일관된 강도

-

강도

-

차원 안정성

7. 303 스테인레스 스틸 원형 막의 응용

가공 가능성과 내구성 덕분에 303 둥근 막대는 여러 산업 분야에서 사용됩니다.

일반적인 응용 프로그램

-

정밀 CNC 가공 부품

-

셰프, 핀, 스톱

-

장착장치

-

기어, 고정장치 및 부싱

-

밸브 및 펌프 부품

-

나사, 볼트, 견과류

-

항공용 커넥터

-

자동차 정밀 부품

-

식품기계 부품

-

해양용 하드웨어 (비판적인 부품)

303 둥근 막대 를 사용하는 산업

-

자동차

-

항공우주

-

기계 제조

-

전자제품

-

해양 장비

-

식품 가공

-

의료기기 (임플란트 없는)

-

산업 자동화

8비교: 303 대 304 대 316 스테인리스 스틸

표 5: 자료 비교

| 재산 | 303 | 304 | 316 |

|---|---|---|---|

| 가공 능력 | 훌륭해요 | 좋아 | 공평하다 |

| 부식 저항성 | 좋아 | 아주 좋네요 | 훌륭해요 |

| 강도 | 중등성 | 높은 | 높은 |

| 용접 가능성 | 공평하다 | 훌륭해요 | 훌륭해요 |

| 신청서 | 기계장치, 부착장치 | 일반용품 | 높은 부식 저항성 |

기계가 가장 중요하다면303이 제일 좋은 선택입니다..

부식 저항성 또는 용접성이 더 중요하다면, 고려304 또는 316.

9제조 공정

높은 정밀도와 밝은 표면을 얻기 위해, 우리의 303 스테인리스 스틸 둥근 막대는:

-

금속 또는 금속제품

-

개선 된 관용 및 완성도를 위해 냉면

-

우수한 표면 품질을 위해 중심이없는 밀링

-

각종 길이로 절단

-

최종 검사 및 시험

10품질 보장

303 스테인리스 스틸 원형 막대 한 각 팩은 다음을 위해 테스트 됩니다:

-

화학적 성질

-

기계적 강도

-

차원 정확성

-

표면 품질

-

단단함

-

직선성

사용 가능한 인증서:

-

EN / ASTM / JIS 표준

-

밀링 테스트 보고서 (MTR)

-

RoHS 준수

11포장 및 배달

제품이 완벽한 상태로 도착하는지 확인하기 위해:

포장 옵션

-

방수 플라스틱 포장재

-

경직 방지 종이

-

목재 케이스 또는 팔레트

-

수출용 맞춤형 포장

배달 옵션

-

해상 운송

-

항공 화물

-

긴급 주문에 대한 급송물

12왜 우리의 고 정밀 303 스테인리스 스틸 둥근 바를 선택합니까?

-

일관성 있고 신뢰할 수 있는 재료 품질

-

대용량 주문에 대한 경쟁력 있는 가격

-

안정적인 재고 가용성으로 빠른 배송

-

전문 기술 지원

-

사용자 정의 가공 솔루션 사용 가능

13주문 정보

요금을 요청하려면 다음을 제공하십시오.

-

필요한 지름

-

길이

-

허용 수준

-

표면 마감

-

양

-

배달 목적지

우리의 기술 및 판매 팀은 상세한 가격과 납품 시간으로 신속하게 응답합니다.

이 기능을 전체 목적지 페이지로 확장하거나 메타데이터, 키워드 또는 스키마 마크업을 추가하는 데 도움이 필요한 경우