-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Custom Cut 317L Stainless Steel Sheet and Plate Mill Finish or Polished Surface

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL TISCO |

| Certification | ISO |

| Model Number | 317L / S31703 |

| Minimum Order Quantity | 50 kgs |

| Price | 5 - 8 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Sheet | Grade | 317L/S31703 |

|---|---|---|---|

| Thickness | 1.0-80.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B BA NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | 317L stainless steel sheet,mill finish stainless steel plate,polished stainless steel plate |

||

Custom Cut 317L Stainless Steel Sheet and Plate Mill Finish or Polished Surface

Stainless Steel Sheet Specifications

| Name | 317L stainless steel sheet |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

Introduction

317L stainless steel is a high-performance material widely used in industrial applications that require superior corrosion resistance and structural integrity. A low-carbon variant of 317 stainless steel, 317L is specially designed to resist corrosion in harsh environments, including exposure to chlorides, acids, and high-temperature conditions. Its versatile properties make it the material of choice in industries such as chemical processing, marine applications, food processing, and power generation.

When choosing 317L stainless steel for industrial applications, it is essential to consider the surface finish and custom cutting options to meet specific requirements. Mill finish and polished surface are two common options for 317L stainless steel sheets and plates, each offering unique benefits depending on the application.

This article will delve into the features and benefits of custom cut 317L stainless steel sheet and plate, exploring both mill finish and polished surface options, their characteristics, and the typical uses of each finish. We will also discuss the importance of custom cutting to meet precise dimensions for various applications.

What is 317L Stainless Steel?

317L stainless steel is an austenitic alloy, primarily composed of 18-20% chromium, 11-15% nickel, and 3-4% molybdenum. The low carbon content (≤ 0.03%) in 317L minimizes the risk of carbide precipitation during welding, which significantly reduces the risk of intergranular corrosion. The addition of molybdenum enhances its resistance to pitting corrosion and crevice corrosion, making it suitable for harsh environments, particularly those containing chloride or acidic compounds.

317L stainless steel exhibits excellent mechanical properties, such as high tensile strength (515 MPa) and yield strength (205 MPa), combined with good ductility and weldability, which make it highly versatile in manufacturing and fabrication.

Mill Finish vs. Polished Surface: Understanding the Differences

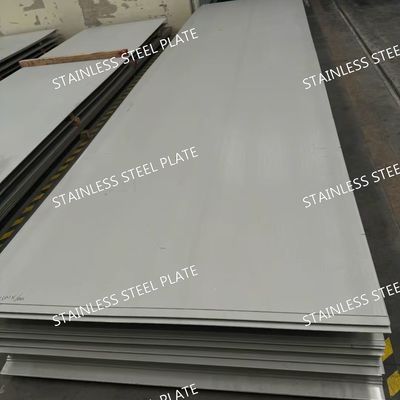

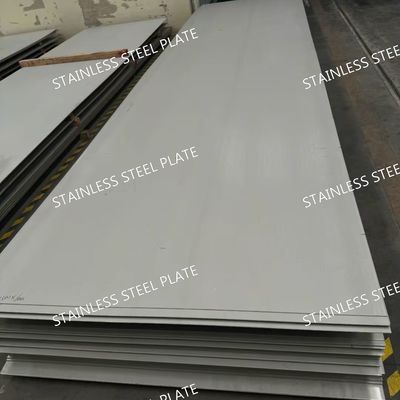

When choosing 317L stainless steel sheets and plates, one of the most critical decisions is selecting the surface finish. The finish of the material not only affects the appearance but also influences its performance, especially in environments where cleanliness, corrosion resistance, and durability are essential. Mill finish and polished surface are the two primary surface treatments available for 317L stainless steel.

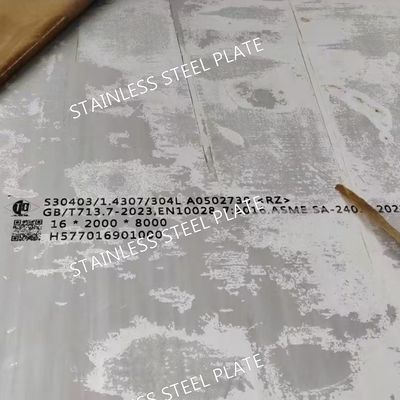

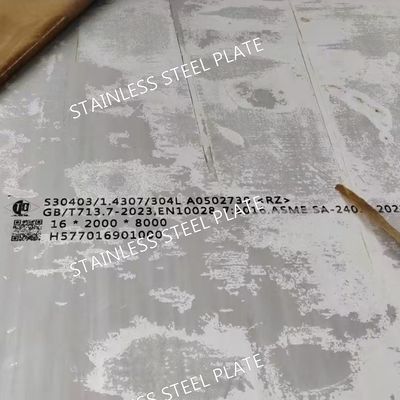

Mill Finish

A mill finish refers to the raw, untreated surface of stainless steel that results directly from the rolling process. It is typically dull and has visible surface imperfections, such as mill scale and light scratches. This is the least expensive surface finish option and is commonly used for industrial applications where appearance is not a priority but strength and corrosion resistance are.

Advantages of Mill Finish 317L Stainless Steel Plate:

-

Cost-Effective

Mill-finished stainless steel is less expensive than polished steel, making it an economical choice for large-scale projects where appearance is secondary to performance. -

Corrosion Resistance

Despite its rough surface, mill finish stainless steel maintains excellent resistance to corrosion, particularly in environments exposed to aggressive chemicals, seawater, or high-temperature conditions. -

Durability

The mill finish provides good durability and resistance to wear, making it suitable for applications that involve heavy-duty handling or harsh environments. -

Weldability

Mill finish 317L is easy to weld, making it ideal for use in applications where the material will undergo further processing, such as welding, forming, or cutting.

Typical Applications of Mill Finish 317L Stainless Steel:

-

Structural components in chemical plants, power stations, and refineries.

-

Industrial tanks and piping systems for handling aggressive chemicals.

-

Heat exchangers exposed to corrosive fluids.

-

Marine equipment exposed to saltwater and other harsh conditions.

Polished Surface

A polished surface refers to stainless steel that has undergone additional processes to improve the finish and appearance of the metal. The polishing process involves mechanically grinding the surface to remove imperfections and achieve a smooth, shiny surface. Polished stainless steel can range from a #2B finish (a smooth, reflective surface) to a #8 mirror finish, which is highly reflective and often used for decorative purposes.

Advantages of Polished 317L Stainless Steel Plate:

-

Enhanced Aesthetic Appeal

Polished stainless steel provides a shiny, reflective surface that enhances the appearance of components. This is particularly important in applications where the visual aspect of the material is critical, such as architectural features and decorative elements. -

Improved Corrosion Resistance

The polishing process helps to smooth out the surface, removing any rough spots where corrosion could initiate. Polished surfaces are less prone to surface corrosion and can offer enhanced protection in some environments. -

Easier Cleaning and Maintenance

The smooth, shiny surface of polished stainless steel is easier to clean and maintain, as there are fewer crevices or rough spots where dirt and grime can accumulate. This is especially important in food processing, pharmaceutical, and medical applications. -

Superior Durability in Certain Applications

A polished finish not only improves the appearance of the material but also adds an extra layer of protection against corrosion. This makes it suitable for applications where long-term performance and ease of maintenance are critical.

Typical Applications of Polished 317L Stainless Steel:

-

Food processing equipment that requires a clean and sanitary surface.

-

Medical and pharmaceutical equipment where hygiene is paramount.

-

Architectural applications such as facades, handrails, and decorative panels.

-

Cosmetic and high-end products that benefit from an aesthetically pleasing, reflective finish.

Custom Cutting of 317L Stainless Steel Plate

One of the key advantages of 317L stainless steel plate is the ability to custom cut the material to meet specific dimensional requirements for a wide range of applications. Custom cutting allows manufacturers and fabricators to obtain precise, ready-to-use parts that fit directly into their systems, reducing waste and improving overall efficiency.

Advantages of Custom Cutting:

-

Tailored Dimensions

Custom cutting ensures that the stainless steel sheet or plate fits perfectly into the desired application without the need for additional processing. Whether it's a specific shape, size, or configuration, custom cutting offers flexibility to meet design requirements. -

Reduced Waste

By obtaining custom-cut pieces, industries can minimize waste and reduce the need for further processing, resulting in cost savings and improved material utilization. -

Increased Productivity

Custom-cut 317L plates can be directly incorporated into the manufacturing process without additional handling, reducing the time required for fabrication and accelerating project timelines. -

Optimized Performance

Cutting to precise dimensions allows for optimal material properties to be utilized in critical parts of the system. For instance, custom cuts can ensure that the stainless steel plate maintains its structural integrity, corrosion resistance, and durability in demanding environments.

Custom Cutting Techniques:

-

Laser Cutting: Offers high precision and the ability to create intricate shapes and designs, making it ideal for applications requiring tight tolerances and complex geometries.

-

Waterjet Cutting: A cold-cutting method that prevents thermal distortion, making it suitable for applications where the material must retain its original properties.

-

Plasma Cutting: A faster and cost-effective cutting method for thicker plates, commonly used in industrial applications that require large quantities of material.

-

Shearing and Stamping: Ideal for producing large numbers of uniform cuts with minimal waste.

Comparison of Mill Finish and Polished 317L Stainless Steel Plate

| Feature | Mill Finish 317L Stainless Steel | Polished 317L Stainless Steel |

|---|---|---|

| Surface Finish | Dull, rough, mill scale present | Shiny, smooth, and reflective |

| Cost | More cost-effective | Higher cost due to additional polishing process |

| Corrosion Resistance | Good, but may have localized imperfections | Enhanced due to smooth, uniform surface |

| Aesthetic Appeal | Functional, but not aesthetically pleasing | Highly reflective, visually appealing |

| Durability | Durable for industrial applications | Durable, with added resistance to corrosion and wear |

| Ease of Maintenance | Requires more frequent cleaning due to rough surface | Easy to clean and maintain due to smooth surface |

| Applications | Chemical processing, heat exchangers, structural components | Food processing, medical equipment, decorative elements |

| Custom Cutting Options | Available in custom sizes and shapes | Available in custom sizes, often with more precision due to smooth finish |

Conclusion

317L stainless steel offers exceptional performance in corrosive environments, making it a versatile choice for a wide variety of industrial applications. Whether you choose a mill finish or a polished surface, each option provides unique benefits depending on the requirements of your project. Mill finish is ideal for applications where performance and cost-effectiveness are paramount, while polished surface is perfect for projects requiring superior aesthetics, corrosion resistance, and ease of maintenance.

![]()

![]()

![]()

![]()