-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

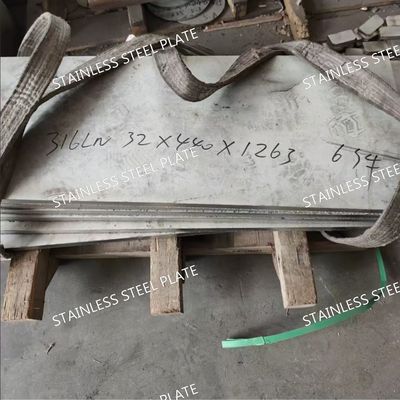

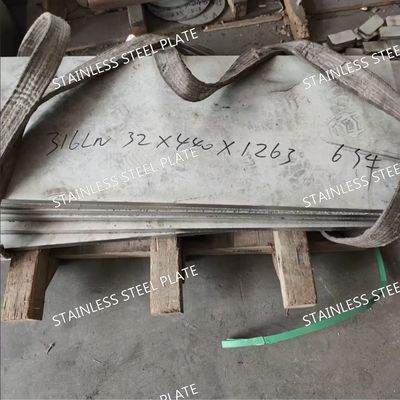

316LN Stainless Steel Plate Hot Rolled and Forged High-Performance SS Plate

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Plate | Grade | 304 304L 316L 316LN 310S 321 2205 2304 2507 904L 254SMO 630 .etc |

|---|---|---|---|

| Thickness | 1.0 - 80.0mm | Width | 1219mm 1500mm 1800mm |

| Surface | NO.1 2B | Brand | BAOSTEEL TISCO |

| Standard | ASTM EN DIN JIS GB | Loading Port | Shanghai Port |

| Highlight | 316LN stainless steel plate hot rolled,forged high-performance SS plate,stainless steel plate with warranty |

||

316LN Stainless Steel Plate Hot Rolled and Forged High-Performance SS Plate

Products Specification

| Products Name | 316LN Stainless Steel Plate Sheet |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316LN,316TI, 317L, 321, 321H, 347,348, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2304,2507.etc |

| Thickness | 0.6 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Service | Laser Cutting |

| Form | Plate / sheet |

| Cutting Shape | Round , Square, or any special shape as request |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

316LN Stainless Steel Plate Hot Rolled and Forged High-Performance SS Plate

Product Overview

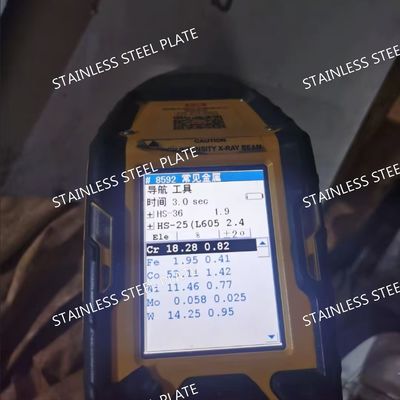

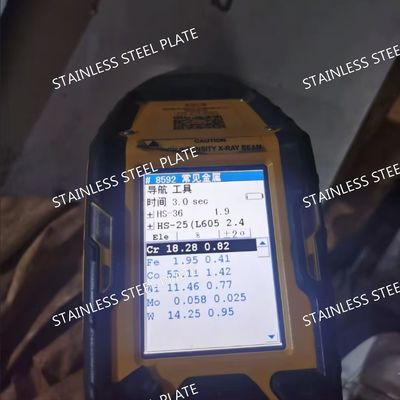

316LN stainless steel is a high-performance, austenitic steel alloy known for its outstanding corrosion resistance, strength, and toughness. This alloy, a low-carbon version of 316 stainless steel, has the added benefit of nitrogen for improved strength and resistance to pitting, crevice corrosion, and stress corrosion cracking. The 316LN stainless steel plate is available in hot-rolled and forged forms, ensuring superior mechanical properties and structural integrity.

316LN stainless steel plates are widely used in various industries such as chemical processing, marine, power generation, aerospace, and petrochemical industries. The combination of excellent corrosion resistance and high strength makes it ideal for applications where high performance is required in extreme conditions.

Key Features and Benefits

-

Superior Corrosion Resistance: Exceptional resistance to a wide range of chemicals, including sulfuric acid, phosphoric acid, and seawater.

-

High Strength: Due to the nitrogen content, it exhibits greater tensile and yield strength compared to standard 316 stainless steel.

-

Stress Corrosion Cracking Resistance: Enhanced resistance to stress corrosion cracking in chloride environments.

-

Versatile Applications: Ideal for industries like chemical processing, marine engineering, medical devices, and food processing.

-

Temperature Resistance: Retains its strength and stability in high-temperature environments.

Product Specifications

Below are the key specifications for 316LN stainless steel plates.

| Parameter | Value |

|---|---|

| Alloy Type | Austenitic stainless steel |

| Grade | 316LN |

| Standard | ASTM A240, ASTM A276, ASTM A479, EN 10088 |

| Thickness Range | 3mm to 150mm |

| Width Range | 1000mm to 2500mm |

| Length Range | 2000mm to 6000mm |

| Density | 8.0 g/cm³ |

| Tensile Strength | 520-720 MPa |

| Yield Strength | 205 MPa |

| Elongation | 40% (min) |

| Hardness | 170 HB |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 16.2 W/m·K |

| Melting Point | 1375-1400°C |

| Coefficient of Expansion | 16.0 × 10⁻⁶ /°C |

Mechanical Properties

316LN stainless steel plates are known for their excellent mechanical properties, which include both high strength and good ductility. These properties make them suitable for use in demanding environments, especially in situations where resistance to corrosion, heat, and stress is required.

-

Tensile Strength: 520-720 MPa

-

Yield Strength: 205 MPa (minimum)

-

Elongation: 40% (minimum)

-

Hardness: 170 HB

-

Modulus of Elasticity: 200 GPa

These properties are critical when the material is used in structural applications or in environments that subject the material to high stresses, like pressure vessels or marine structures.

Production Standards

316LN stainless steel plates are produced in accordance with several international and industry standards to ensure their quality and performance:

-

ASTM A240: Covers stainless steel plates, sheets, and strips for pressure vessels and general corrosion-resistant applications.

-

ASTM A276: Standard specification for stainless steel bars and shapes.

-

ASTM A479: Standard specification for stainless steel bars for use in boilers and other high-temperature service.

-

EN 10088: European standard for stainless steel products.

-

ISO 9001: Quality management system standards to ensure consistent product quality.

-

NACE MR0175: For sour service applications, ensuring resistance to sulfide stress cracking.

Applications

316LN stainless steel plates are ideal for various applications, particularly in environments where durability and resistance to corrosion are crucial. Some of the most common applications include:

-

Marine and Offshore Structures: Due to its excellent resistance to saltwater corrosion.

-

Chemical Processing: Used in equipment like heat exchangers, reactors, and piping systems that handle aggressive chemicals.

-

Aerospace Industry: Aircraft components that need to resist both high stress and environmental exposure.

-

Food Processing Equipment: With its corrosion resistance and easy cleaning properties, it’s widely used in food-related manufacturing systems.

-

Medical Devices: Because of its non-reactive properties and biocompatibility.

-

Power Plants: Especially in high-temperature systems like steam turbines and boilers.

Packaging and Shipping

316LN stainless steel plates are packaged and shipped with care to ensure they arrive at their destination without damage. The packaging process includes:

-

Protection: Plates are wrapped in plastic film to protect against moisture and dust. They are then carefully placed in wooden or steel crates.

-

Marking: Each package is clearly marked with relevant details like grade, dimensions, and certification.

-

Shipping: The material is shipped globally via sea, air, or land transport depending on the customer’s location. Sea freight is commonly used for bulk orders.

Shipping Lead Time: 7-14 days depending on the region and order size.

Handling & Storage: To avoid surface damage, it is recommended to store stainless steel plates in a clean, dry, and well-ventilated area. Plates should be stacked flat on pallets, avoiding direct contact with the floor.

FAQ (Frequently Asked Questions)

1. What is the difference between 316L and 316LN stainless steel?

The main difference lies in the nitrogen content. 316LN has added nitrogen which enhances its strength, especially under extreme conditions. This makes it more resistant to stress corrosion cracking and enhances its overall performance compared to standard 316L stainless steel.

2. Can 316LN stainless steel be welded?

Yes, 316LN can be welded. However, it is recommended to use a low-carbon filler material to ensure that no carbide precipitation occurs during the welding process, which can affect corrosion resistance.

3. What is the maximum temperature that 316LN stainless steel can withstand?

316LN stainless steel can withstand temperatures up to 870°C (1600°F) intermittently and 925°C (1700°F) continuously without significant loss of strength.

4. Is 316LN stainless steel magnetic?

316LN stainless steel is non-magnetic in the annealed condition. However, it may become slightly magnetic when cold-worked.

5. How should 316LN stainless steel be cleaned and maintained?

316LN stainless steel is resistant to rust and corrosion, but regular cleaning is essential to maintain its appearance and properties. Use mild soap or detergent, warm water, and a soft cloth to clean the surface. Avoid harsh chemicals or abrasive cleaners.

6. Can 316LN stainless steel be used in cryogenic applications?

Yes, 316LN performs well in cryogenic temperatures and is often used in liquefied natural gas (LNG) storage and transport.

7. What industries typically use 316LN stainless steel plates?

Industries such as chemical processing, marine, aerospace, power generation, medical devices, and food processing often use 316LN stainless steel due to its superior corrosion resistance and high strength.

Conclusion

316LN Stainless Steel Plates are a high-performance material that offers superior strength, corrosion resistance, and versatility for a variety of applications. Whether used in marine, chemical, or medical industries, this material ensures reliability and durability in harsh conditions. With the option of hot-rolled and forged forms, 316LN stainless steel plates meet international standards and are packaged and shipped to provide maximum protection and efficiency.

![]()

![]()

![]()

![]()