All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

UNS S32750 / Alloy 2507 Duplex Stainless Steel Pipe Tube SS Pipe for High Pressure Equipment

Product Details

| Products | Stainless Steel Seamless Pipe | Grade | S32750 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | Alloy 2507 duplex stainless steel pipe,UNS S32750 high pressure pipe,duplex stainless steel tube for equipment |

||

Product Description

UNS S32750 / Alloy 2507 Duplex Stainless Steel Pipe Tube SS Pipe for High Pressure Equipment

Products Specification

| Products Name | Duplex 2507 Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

UNS S32750, also known as Alloy 2507, is a super duplex stainless steel pipe/tube renowned for its exceptional combination of strength, corrosion resistance, and toughness. This material is classified as a duplex stainless steel, meaning it has a microstructure consisting of approximately 50% austenite and 50% ferrite, which gives it advantages over both austenitic and ferritic stainless steels. Specifically designed to perform under high-pressure and aggressive environments, 2507 duplex stainless steel pipes are widely used in industries where reliability and durability under extreme conditions are critical.

Chemical Composition (Weight %) of Duplex 2507 Stainless Steel Pipe

| Element | Content Range |

|---|---|

| Chromium (Cr) | 24.0 - 26.0 |

| Nickel (Ni) | 6.0 - 8.0 |

| Molybdenum (Mo) | 3.0 - 5.0 |

| Nitrogen (N) | 0.14 - 0.20 |

| Iron (Fe) | Balance |

| Carbon (C) | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.02 |

Mechanical Properties of Duplex 2507 Stainless Steel Pipe

| Property | Value |

|---|---|

| Tensile Strength | ≥ 800 MPa |

| Yield Strength (0.2% offset) | ≥ 550 MPa |

| Elongation | ≥ 15% |

| Hardness (Rockwell C) | ≤ 31 |

| Impact Strength (Charpy V-notch, -40°C) | ≥ 40 J |

Key Features of Duplex 2507 Stainless Steel Pipe

- Excellent Corrosion Resistance: Resistant to pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-rich environments (e.g., seawater, brines).

- High Strength: Twice the yield strength of austenitic stainless steels (e.g., 316L), allowing for thinner wall designs and reduced weight in high-pressure applications.

- Good Toughness: Maintains ductility and impact resistance even at low temperatures.

- Weldability: Can be welded using standard methods (e.g., TIG, MIG) with proper procedure control to preserve duplex microstructure.

- Cost-Effective: Offers a balance of performance and cost compared to higher-nickel alloys (e.g., super austenitic stainless steels).

Standards of Duplex 2507 Stainless Steel Pipe

2507 duplex stainless steel pipes/tubes are manufactured in compliance with various international standards, including:

- ASTM A789 / A789M (Seamless and Welded Ferritic/Austenitic Duplex Stainless Steel Tubing for General Service)

- ASTM A790 / A790M (Seamless and Welded Ferritic/Austenitic Duplex Stainless Steel Pipe for General Service)

- ASME SA789 / SA790

- EN 10216-5 (Welded duplex stainless steel tubes for pressure purposes)

- DIN 17458 (Duplex stainless steel pipes)

Equivalent Grades of Duplex 2507 Stainless Steel Pipe

- UNS S32750

- EN 1.4410

- DIN X2CrNiMoN25-7-4

- JIS SUS 2507

Applications of Duplex 2507 Stainless Steel Pipe

Due to its high strength and corrosion resistance under pressure, 2507 duplex stainless steel pipes are ideal for:

- Oil and gas industry: Offshore drilling equipment, subsea pipelines, and high-pressure wellhead components.

- Chemical processing: Reactors, heat exchangers, and piping handling corrosive chemicals (e.g., acids, chlorides).

- Desalination plants: Seawater intake and reverse osmosis systems.

- Pulp and paper industry: Bleaching systems and processing equipment.

- Power generation: High-pressure boilers and flue gas desulfurization systems.

- Marine engineering: Ship hulls, ballast tanks, and offshore structures.

Export Packaging & Transportation

-

Packaging:

- Pipes are typically bundled with steel straps, wrapped in waterproof plastic film or Hessian cloth to prevent moisture and scratches.

- For small-diameter tubes, they may be packed in wooden crates or pallets with foam inserts for added protection.

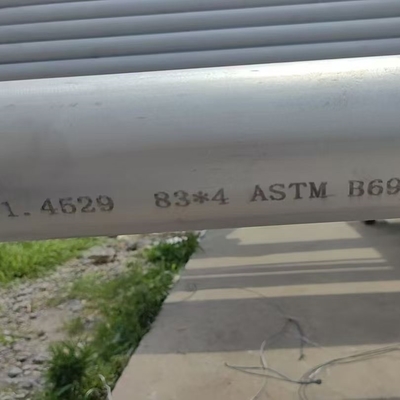

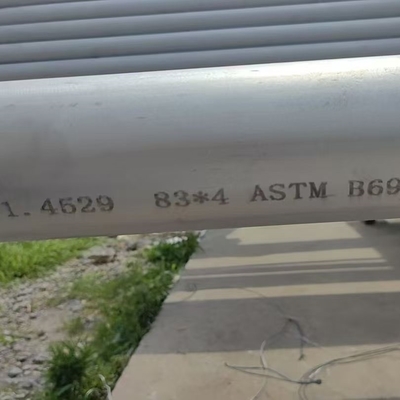

- Each bundle or crate is labeled with details such as material grade, size, quantity, heat number, and certification (e.g., Mill Test Report).

-

Transportation:

- Shipped by sea in containers (20ft or 40ft) for long-distance international transport.

- For land transport, trucks or railcars are used, with proper securing to avoid movement during transit.

- Special handling is provided for large-diameter or heavy-wall pipes to ensure structural integrity.

![]()

![]()

![]()

![]()

Recommended Products