All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Precision Stainless Steel Plate 0.1-30mm 304 316L 2205 Grades

| Place of Origin | China |

|---|---|

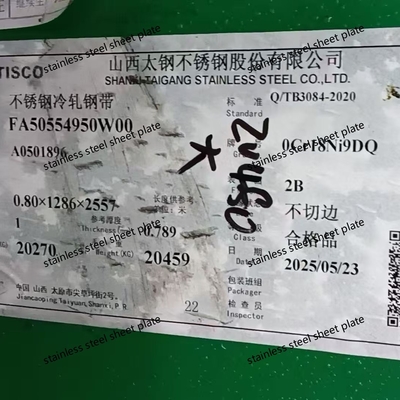

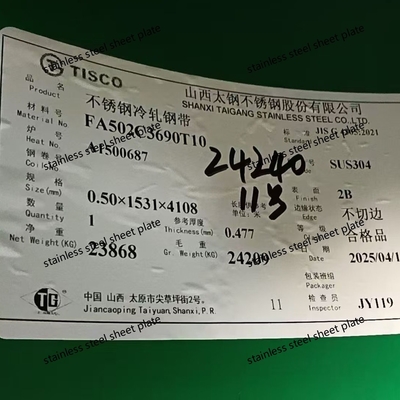

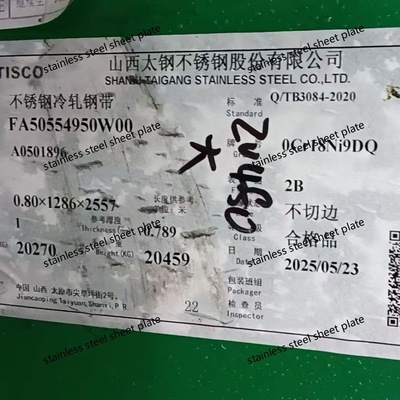

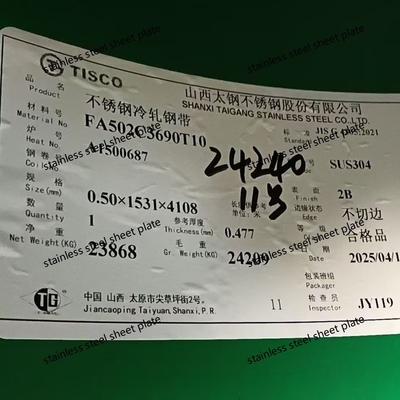

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 5000 - 7200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Plate | Grade | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

|---|---|---|---|

| Thickness | 0.4 -80.0mm | Width | 1219mm 1500mm 1800mm 2000mm |

| Surface | NO.1 2B | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | 304 stainless steel plate,316L stainless steel plate,2205 duplex stainless steel plate |

||

Product Description

Small Tolerance Stainless Steel Plate Thickness 0.1 - 30.0mm SS Plate Width 1000mm 1219mm 1500mm 1800mm 2000mm

Products Specification

| Products Name | Stainless Steel Plate Sheet |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 317L, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2507.etc |

| Thickness | 0.6 - 30.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Service | Laser Cutting |

| Form | Plate / sheet |

| Cutting Shape | Round , Square, or any special shape as request |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

Product Introduction

Our Small Tolerance Stainless Steel Plates are engineered for precision-critical applications, offering thicknesses from 0.1mm to 30.0mm and widths including 1000mm, 1219mm, 1500mm, 1800mm, and 2000mm. Manufactured with tight dimensional tolerances, these plates ensure consistent thickness and flatness, minimizing material waste and enhancing compatibility with high-precision fabrication processes. Available in both hot-rolled and cold-rolled finishes, they combine the inherent corrosion resistance of stainless steel with superior mechanical properties, making them ideal for industries where accuracy and reliability are non-negotiable.

Common Grades

Austenitic Grades

- 304/304L: Balances excellent corrosion resistance in mild environments (e.g., atmospheric, food-grade) with good formability and weldability. 304L (low carbon) reduces carbide precipitation risk during welding.

- 316/316L: Offers superior resistance to chloride-induced corrosion, making them suitable for marine, pharmaceutical, and chemical processing applications. 316L minimizes intergranular corrosion in welded structures.

- 321/347: Stabilized with titanium (321) or niobium (347) to prevent carbide precipitation at high temperatures, ideal for components in furnaces, exhaust systems, and thermal equipment.

Duplex & Super Duplex Grades

- 2205: Combines high strength (double that of austenitic grades) with excellent stress corrosion cracking resistance, used in oil & gas, seawater handling, and pressure vessels.

- 2507: A super duplex grade for extreme environments, offering superior resistance to pitting, crevice corrosion, and high-pressure applications like offshore platforms.

Martensitic & Ferritic Grades

- 430: Magnetic, cost-effective, and resistant to atmospheric corrosion, commonly used in architectural trims, automotive exhausts, and heat-resistant applications.

- 410/420: Hardenable grades with moderate to high hardness (after heat treatment), suitable for knife blades, pump shafts, and mechanical parts requiring wear resistance.

Standards Compliance

These plates adhere to international standards for dimensional accuracy and material performance:

- ASTM A240/A240M: Defines chemical composition, mechanical properties (tensile strength, elongation), and tolerance requirements for stainless steel plates.

- EN 10088-2/EN 10029: European standards specifying technical delivery conditions for flat products, including strict tolerances for thickness, width, and flatness.

- JIS G4305 (Cold-Rolled) / JIS G4304 (Hot-Rolled): Japanese standards ensuring surface quality and dimensional precision for industrial and structural applications.

- GB/T 3280 (China): Mandates tight tolerances for high-precision stainless steel plates used in aerospace, electronics, and medical devices.

Processing Services

Precision Cutting

- Laser Cutting: Achieves micron-level accuracy for complex shapes, ideal for thin plates (0.1–5mm) in electronics and medical devices.

- Waterjet Cutting: Cuts thick plates (up to 30mm) without heat-affected zones, preserving material properties for aerospace and defense components.

- Shearing/Plasma Cutting: Cost-effective solutions for large-scale production, ensuring straight edges and tight width tolerances.

Forming & Fabrication

- Press Bending: High-precision CNC press brakes form plates into channels, angles, or custom profiles with minimal springback, suitable for structural frames and machine enclosures.

- Welding: TIG/MIG welding services for austenitic and duplex grades, with post-weld heat treatment (when required) to maintain dimensional stability and corrosion resistance.

Surface Finishing

- Polishing (2B, BA, Mirror): Enhances aesthetic appeal and hygiene for food processing or architectural applications.

- Passivation/Pickling: Removes surface contaminants and strengthens the protective oxide layer, improving corrosion resistance for marine or chemical environments.

- Embossing/Pattern Rolling: Adds anti-slip textures or decorative patterns for flooring, stair treads, and signage.

Key Advantages

- Ultra-Tight Tolerances: Thickness tolerances as low as ±0.01mm (for thin plates) and ±0.1% (for thick plates), meeting ISO 683-13 and ASME BPVC Section II requirements for critical applications.

- Material Versatility: Available in 20+ grades, covering corrosion resistance, high-temperature stability, and extreme strength needs across industries.

- Surface Quality: Cold-rolled plates offer superior flatness (≤2mm/m) and surface roughness (Ra ≤1.6μm), reducing post-processing efforts for precision components.

- Inventory Flexibility: Wide stock of standard widths and thicknesses, with quick turnaround for custom orders to minimize project delays.

- Traceability & Certification: Full material traceability from mill to delivery, with mill test reports (MTR), PMI certificates, and NDT (ultrasonic/eddy current) reports available upon request.

Applications

Aerospace & Defense

- Wing ribs, fuselage panels, and engine components (321/347 for heat resistance; 2205 for lightweight strength).

- Armor plating and missile parts requiring high impact resistance and dimensional precision.

Medical & Biotechnology

- Surgical instrument trays (316L for biocompatibility), diagnostic equipment enclosures, and implantable device components (polished surface for hygiene).

Electronics & Semiconductors

- Precision shims, heat sinks, and circuit board frames (0.1–1mm thickness with ±0.02mm tolerance for microelectronics).

- Cleanroom-compatible panels resistant to chemical cleaning agents.

Industrial Equipment

- Heat exchanger plates (316L/2205 for corrosion resistance), pump casings, and robotic arm components (420 for wear resistance).

- Precision machine bases and guides requiring minimal thermal expansion.

Architectural & Decorative

- High-gloss facade panels (mirror-finished 304), structural glass supports, and interior cladding with tight width tolerances for seamless installation.

Energy & Renewables

- Solar panel frames (430 for cost-effective corrosion resistance), wind turbine hub components (2507 for offshore durability), and nuclear reactor internals (347 for radiation resistance).

Quality Assurance

Every plate undergoes rigorous testing:

- Dimensional Inspection: Laser scanning and caliper measurements to verify thickness, width, and flatness against target tolerances.

- Mechanical Testing: Tensile, yield, and impact tests to ensure compliance with grade-specific property requirements.

- Corrosion Testing: Salt spray (ASTM B117) and intergranular corrosion (ASTM A262 Practice E) tests for critical environments.

Contact us to discuss your precision stainless steel plate needs, from prototype development to large-scale production. Our engineering team is ready to assist with material selection, tolerance optimization, and custom fabrication solutions.

Recommended Products