All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

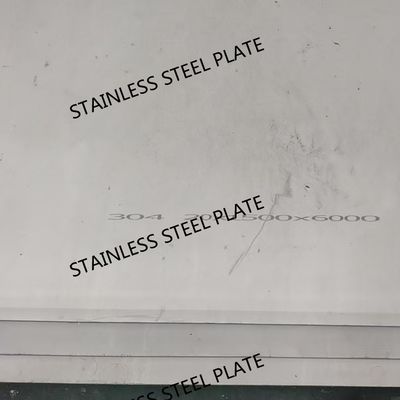

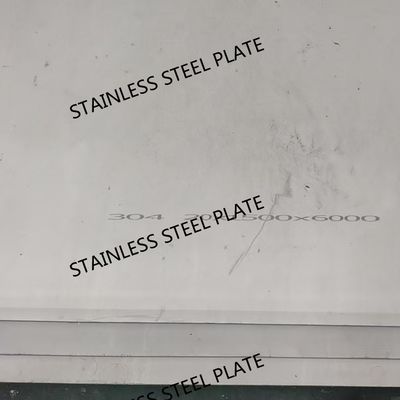

Hot Rolled 316Ti Stainless Steel Plate No.1 Finish Intergranular Corrosion Resistant Industrial Grade

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Plate | Grade | 316Ti |

|---|---|---|---|

| Thickness | 3.0 - 80.0mm | Width | 1500mm 1800mm 2000mm |

| Surface | NO.1 | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Industrial Grade 316Ti Stainless Steel Plate,No.1 Finish 316Ti Stainless Steel Plate,Hot Rolled 316Ti Plate |

||

Product Description

Hot Rolled 316Ti Stainless Steel Plate No.1 Finish, Intergranular Corrosion Resistant, Industrial Grade

Products Specification

| Products Name | 316Ti Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

316Ti Stainless Steel Sheet Product Information

Unveiling the Excellence of 316Ti Stainless Steel Sheets

316Ti stainless steel sheets represent the pinnacle of advanced metallurgical engineering. Engineered to meet the most demanding industrial challenges, this austenitic stainless steel variant offers a remarkable blend of durability, versatility, and corrosion - resistance, positioning it as the material of choice across diverse sectors.

Chemical Makeup and Alloy Synergy

The precise composition of 316Ti stainless steel is the cornerstone of its superior performance. With a carbon content capped at ≤0.08%, a chromium range of 16.0 - 18.0%, and nickel levels between 10.0 - 14.0%, it forms a robust base. The addition of 2.0 - 3.0% molybdenum acts as a corrosion - fighting powerhouse, enabling the material to resist pitting and crevice corrosion even in highly aggressive chloride - laden conditions. Titanium, present at a ratio of ≥5×C%, serves as a stabilizing agent, preventing the formation of detrimental carbide precipitates during thermal cycling and welding operations. This unique alloy combination ensures unrivaled intergranular corrosion resistance, safeguarding the material's integrity over extended service life.

Mechanical Prowess

- Tensile Strength: A minimum of 515 MPa, ensuring robust load - bearing capacity under various stress conditions.

- Yield Strength (0.2% offset): ≥205 MPa, guaranteeing reliable performance without permanent deformation.

- Elongation at Break: ≥40%, endowing the sheets with excellent formability for complex fabrication tasks.

- Hardness (HB): ≤187, striking the perfect balance between workability and wear - resistance.

- Density: 7.98 g/cm³, providing a favorable strength - to - weight ratio for applications where weight is a concern.

These mechanical attributes empower manufacturers to transform 316Ti stainless steel sheets into intricate components, while maintaining structural integrity and longevity.

Distinctive Advantages

- Unyielding Corrosion Resistance: Whether submerged in seawater, exposed to industrial chemicals, or operating in high - humidity environments, 316Ti stainless steel sheets remain impervious to corrosion. This makes them indispensable in marine structures, chemical processing plants, and wastewater treatment facilities.

- Thermal Resilience: Capable of withstanding temperatures up to 800°C (1472°F) without significant loss of mechanical properties, 316Ti stainless steel sheets are well - suited for high - temperature applications such as heat exchangers, furnace parts, and automotive exhaust systems.

- Seamless Weldability: Thanks to the stabilizing effect of titanium, 316Ti stainless steel sheets can be welded with ease. Weld joints exhibit excellent corrosion resistance and mechanical strength, minimizing post - weld treatment requirements and enhancing production efficiency.

- Hygienic and Low - Maintenance: The smooth, non - porous surface of 316Ti stainless steel sheets resists the adhesion of contaminants, making them easy to clean and sanitize. This feature makes them a top pick for the food and beverage, pharmaceutical, and medical device industries, where strict hygiene standards are paramount.

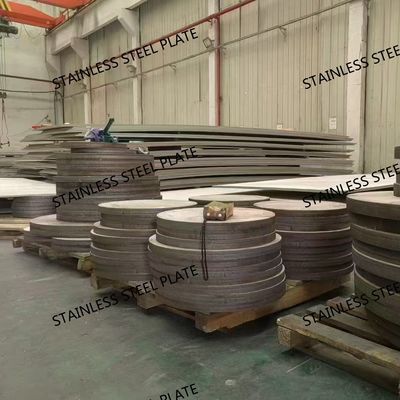

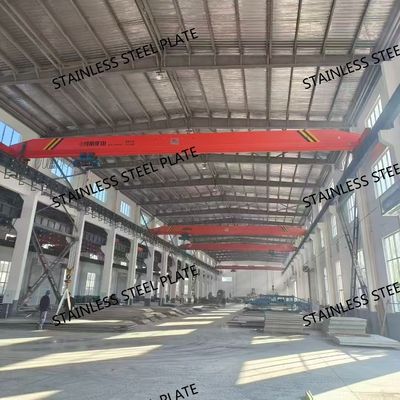

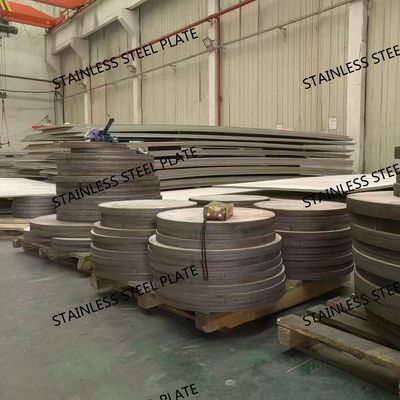

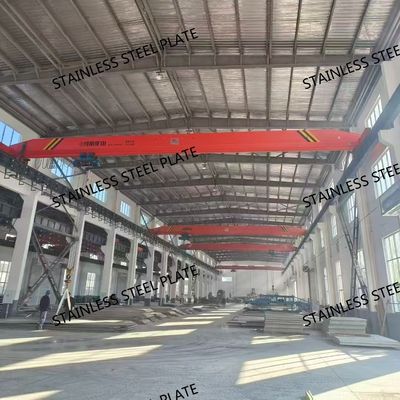

Precision Manufacturing

Our 316Ti stainless steel sheets are crafted through a meticulous manufacturing process. High - grade raw materials are first melted in state - of - the - art electric arc or induction furnaces. The molten alloy is then cast into ingots, which are subsequently hot - rolled to reduce thickness and refine the grain structure. Cold - rolling operations further optimize the sheet's dimensional accuracy and surface finish. To enhance formability and relieve internal stresses, the sheets undergo carefully controlled annealing processes. Rigorous quality checks are conducted at every stage to ensure consistency and compliance with the highest industry standards.

Comprehensive Specifications

- Thickness: Ranging from a thin 0.3 mm for applications requiring flexibility to a robust 50 mm for heavy - duty structures.

- Width: Available in widths from 600 mm to 2000 mm, catering to diverse fabrication needs.

- Length: Custom - cut lengths are available to meet specific project requirements.

- Surface Finishes:

- 2B Finish: A bright, cold - rolled surface with a smooth, reflective appearance, ideal for general - purpose applications.

- BA Finish: A highly polished, bright - annealed surface with enhanced reflectivity, suitable for decorative and architectural uses.

- No. 4 Finish: A satin - like polished surface, providing a balance between aesthetics and functionality.

- HL Finish: Characterized by fine, parallel hairline scratches, offering a unique visual texture.

- Mirror Finish: A highly reflective, mirror - like surface, perfect for high - end decorative applications.

Extensive Applications

- Marine Engineering: Used in the construction of ship hulls, propellers, and offshore platforms, 316Ti stainless steel sheets withstand the corrosive effects of seawater and marine atmospheres, ensuring long - term reliability.

- Chemical Processing: In chemical plants, 316Ti stainless steel sheets are employed in reactors, pipelines, and storage vessels, safely handling a wide range of corrosive chemicals.

- Food and Beverage Production: From food processing equipment and storage tanks to brewing and dairy facilities, 316Ti stainless steel sheets meet strict hygiene requirements while offering excellent corrosion resistance.

- Pharmaceutical Industry: In pharmaceutical manufacturing, 316Ti stainless steel sheets are used in equipment, cleanrooms, and storage systems, ensuring product integrity and compliance with stringent regulatory standards.

- Architectural Design: With its attractive appearance and durability, 316Ti stainless steel sheets are used for exterior facades, interior decorations, handrails, and balustrades, adding a touch of elegance to buildings while withstanding the elements.

Unwavering Quality Assurance

Quality is at the heart of our 316Ti stainless steel sheet production. Our products adhere to international standards such as ASTM A240, EN 10088, and JIS G4305. Each batch undergoes comprehensive testing, including chemical analysis, mechanical property evaluation, non - destructive testing (NDT) methods like ultrasonic and eddy current testing, and visual inspection. Our ISO 9001 - certified quality management system ensures that every 316Ti stainless steel sheet leaving our facility meets the highest quality benchmarks, providing our customers with products they can trust.

![]()

![]()

![]()

![]()

Recommended Products