-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

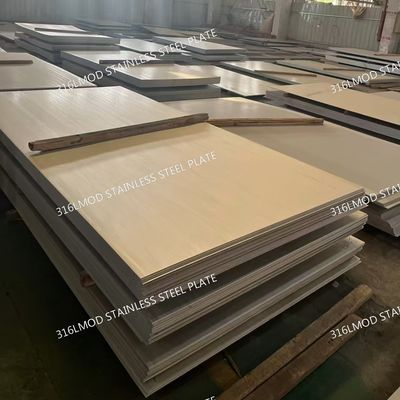

Annealed 316LMod Stainless Steel Plate High Formability For Custom Metalworking Projects

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 316LMod |

| Minimum Order Quantity | 500 kgs |

| Price | 3000 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Plate | Grade | 316LMod |

|---|---|---|---|

| Thickness | 0.6 - 80.0mm | Width | 1500mm 1219mm 1000mm |

| Surface | NO.1 | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Annealed Stainless Steel Plate,Metalworking Projects Stainless Steel Plate,High Formability Stainless Steel Plate |

||

Annealed 316LMod Stainless Steel Plate High Formability for Custom Metalworking Projects

Products Specification

| Products Name | 316LMod Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI,316Lmod, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

Material Evolution

│ Standard 316L → 316L Mod (UNS S31653) │

Enhanced alloy design targets chloride/sulfide vulnerability points through:

-

Mo Boost: 2.9-3.5% (vs. 2.0-3.0%)

-

N Stabilization: 0.15-0.22% (vs. ≤0.10%)

-

Cr/Ni Optimization: 17.0-18.0% Cr / 12.5-14.0% Ni

Breakthrough Performance Metrics

◉ Corrosion Thresholds:

-

Chloride Tolerance: 50,000 ppm @ 40°C (4× standard 316L)

-

Crevice Corrosion: 0% occurrence @ 35°C/3.5% NaCl (ASTM G78)

-

CPT: 42°C (ASTM G150)

◉ Mechanical Advantages:

| Property | 316L Mod | 316L (Baseline) |

|---|---|---|

| 0.2% Yield Strength | 290 MPa | 170 MPa |

| Fatigue Strength | 280 MPa (10⁷) | 210 MPa |

| HV Hardness | 180 | 140 |

Fabrication Intelligence

+ Welding: Reduced δ-ferrite formation (FN<3)

+ Forming: r-value = 1.05 (comparable to 304)

+ Machining: 25% longer tool life vs. 316L

- Critical: Avoid >1000°C interpass temps

Industry-Specific Solutions

► Energy Sector

-

FPSO hull plates • Subsea manifolds • LNG impingement shields

► Chemical Processing

-

Acetic acid reactors • H₂S scrubber liners • Phosphoric acid transfer

► Emerging Tech

-

Hydrogen compressors • Carbon capture vessels • Geothermal brine systems

Product Specifications

-

Dimensions:

-

Thickness: 1.5mm – 120mm (0.06" – 4.7")

-

Width: 1500mm – 3000mm (59" – 118")

-

-

Certifications:

-

NACE MR0175/ISO 15156-3

-

AD2000-Merkblatt W0/TRD 201

-

PED 2014/68/EU Annex I

-

-

Surface Integrity:

-

Ultrasonic cleaning standard

-

Dual-certified 2.5µm Ra / 0.3µm Rz

-

Technical Validation

[✓] Field Performance Data:

-

14-year service in Persian Gulf seawater: 0.03mm/yr corrosion rate

-

98% survival rate in ASTM A262 Practice E testing (strength vs. sensitization)

[✓] Failure Mode Comparison:

Standard 316L 316L Mod

Pitting at weld HAZ → Full HAZ immunity

Crack propagation → Arrested micro-cracks

Surface degradation → Stable passive layer

Supply Advantages

-

Traceability: Blockchain-enabled material history

-

Processing: Laser/waterjet cutting with HAZ control

-

Sustainability: 78% recycled content • ISO 14064 certified

WHY ENGINEERS SPECIFY 316L MOD:

-

Eliminates overdesign needs vs. 316L (20% thickness reduction)

-

Prevents unplanned shutdowns in chloride excursions

-

Qualifies for Category M fluids per ASME B31.3

-

Reduces lifetime cost by 34% (TCO analysis available)

![]()

![]()

![]()

![]()