-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

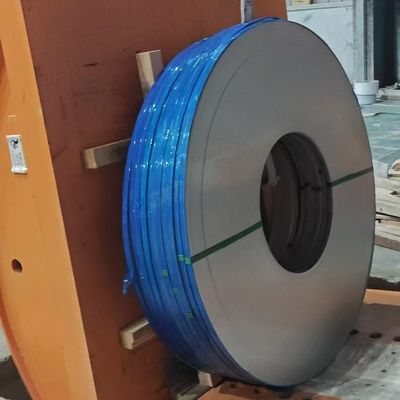

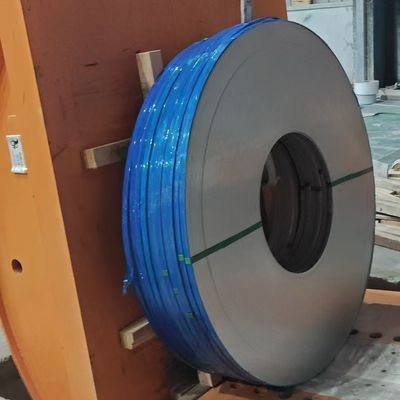

444 Stainless Steel Coil Strip Heat-Resistant, Ideal for Automotive & Industrial Use

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Strip | Thickness | 0.5-3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 400 Series | Surface | BA 2B |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

Products Specification

| Product Name | SUS444 Stainless Steel Strips |

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.15 - 3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,444,904L,2205,2507,630,631.etc |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

Product Name: 444 Stainless Steel Strip

Grade Specifications: UNS S44400 / EN 1.4521

Innovative Solution for Corrosive Environments

444 stainless steel strip is a premium ferritic alloy engineered to deliver outstanding performance in aggressive and high-temperature settings. Unlike conventional austenitic steels, it combines chromium and molybdenum to combat localized corrosion while maintaining cost efficiency. Ideal for industries demanding durability without the price tag of nickel-heavy alloys.

Core Advantages

-

Chloride Resistance: Excels in seawater, chemical, and coastal applications.

-

Zero Nickel Design: Reduces costs and price volatility linked to nickel markets.

-

Thermal Stability: Retains strength at elevated temperatures (up to 400°C/752°F).

-

Eco-Friendly: Fully recyclable and compliant with RoHS standards.

-

Low Maintenance: Resists scaling and oxidation in humid or acidic conditions.

Performance Highlights

-

Stress Corrosion Cracking (SCC) Resistance: Superior to 304/316 in chloride-rich settings.

-

Pitting Resistance Equivalent (PRE): ≥24, ensuring reliability in harsh media.

-

Fatigue Strength: Enhanced cyclic load tolerance for dynamic applications.

Technical Specifications

Chemical Composition

-

Cr: 17.5–19.5% | Mo: 1.75–2.5% | C: ≤0.025% | N: ≤0.035% | Fe: Balance

Mechanical Properties

-

Tensile Strength: 415–550 MPa | Yield Strength: 275–350 MPa

-

Elongation: ≥20% | Hardness (Annealed): 170–200 HV

Physical Attributes

-

Density: 7.75 g/cm³ | Thermal Expansion: 10.4 μm/m·K (20–100°C)

-

Magnetic Response: Fully magnetic, suitable for sensors and electronic housings.

Customization Options

-

Thickness & Width: Ranges from ultra-thin 0.05mm foil to 5mm heavy-duty strips.

-

Surface Treatments:

-

Passivated: Enhanced corrosion protection.

-

Embossed: Anti-slip textures for industrial flooring.

-

PVD Coating: Decorative or functional color finishes.

-

-

Temper Options: Soft annealed, 1/4 hard, 1/2 hard for tailored strength.

Industry-Specific Applications

-

Renewable Energy: Solar panel frames, geothermal piping.

-

Water Infrastructure: Desalination plants, wastewater treatment systems.

-

Medical Devices: Sterilization trays, surgical tool components.

-

Consumer Appliances: Dishwasher linings, refrigerator condensers.

-

Transportation: Marine hardware, railcar fittings.

Why Choose 444 Over Alternatives?

-

Cost-Efficiency: 30–40% lower lifecycle cost vs. 316L in chloride environments.

-

Simplified Fabrication: No post-weld annealing required, reducing processing time.

-

Sustainability: 98% recyclability rate, aligning with green manufacturing goals.

Quality Assurance

-

Certifications: ISO 9001, ASTM A176, and PED 2014/68/EU compliant.

-

Testing Protocols: Third-party validated for intergranular corrosion (ASTM A763) and eddy current flaw detection.

-

Traceability: Full material batch tracking via digital MTCs (Mill Test Certificates).

Packaging & Delivery

-

Standard: VCI (Volatile Corrosion Inhibitor) film + waterproof wrapping.

-

Special Requests: Vacuum-sealed packs for critical applications.

-

Lead Time: 2–4 weeks for bulk orders; expedited shipping available.

Contact Us Today!

Request free samples or discuss custom specifications with our metallurgy experts. Ideal for OEMs seeking reliable, budget-friendly stainless solutions.

![]()

![]()

![]()

![]()