-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

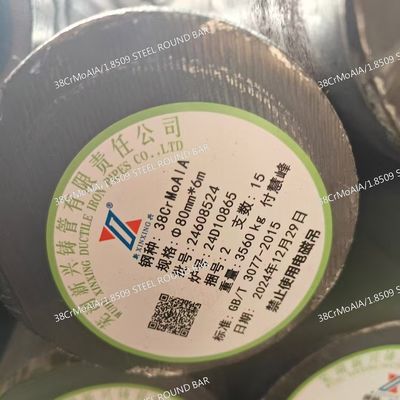

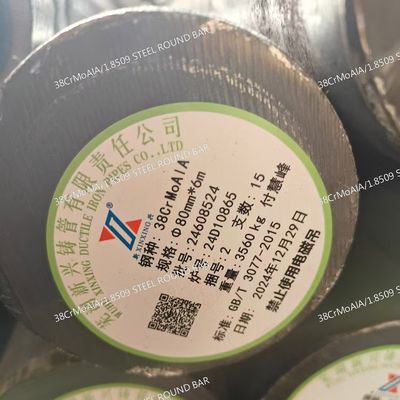

38CrMoAlA/1.8509 Alloy Round Bar Heat Treated For Enhanced Performance

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 31CrMoV9(1.8509)/ 38CrMoAlA |

| Minimum Order Quantity | 1 Ton |

| Price | 600-850 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products Name | Alloy Steel Round Bar | Diameter | 10 - 300mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

| Highlight | 38CrMoAlA Alloy Round Bar,1.8509 Alloy Round Bar,Heat Treated Alloy Round Bar |

||

38CrMoAlA/1.8509 Alloy Round Bar Heat Treated for Enhanced Performance

Products Specification

|

Products Name |

38CrMoAlA/1.8509 Nitriding Steel Round Bar |

|

Diameter |

10 - 300 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo,304,3 16,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,5CrMnMo ,38CrMoAl, 31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Standard Size of our Steel Round Bar In Stock

| 10mm | 12mm | 15mm | 16mm | 18mm | 20mm |

| 25mm | 30mm | 35mm | 38mm | 40mm | 42mm |

| 45mm | 48mm | 50mm | 55mm | 60mm | 65mm |

| 70mm | 75mm | 80mm | 85mm | 90mm | 95mm |

| 105mm | 110mm | 115mm | 120mm | 130mm | 140mm |

| 150mm | 160mm | 170mm | 180mm | 190mm | 200mm |

| 210mm | 220mm | 230mm | 240mm | 250mm | 260mm |

| 270mm | 280mm | 290mm | 300mm | 310mm | 320mm |

38CrMoAlA/1.8509 Alloy Steel Round Bar

Material Standard: DIN 1.8509 / GB/T 3077 (Equivalent to Chinese Standard)

Overview

38CrMoAlA (DIN 1.8509) is a high-quality chromium-molybdenum-aluminum alloy steel specifically designed for nitriding treatment. It exhibits exceptional surface hardness, wear resistance, and fatigue strength after nitriding, making it ideal for high-stress components requiring superior durability and dimensional stability.

Chemical Composition

| Element | C | Cr | Mo | Al | Mn | Si | P (max) | S (max) |

|---|---|---|---|---|---|---|---|---|

| % | 0.35-0.42 | 1.35-1.65 | 0.15-0.25 | 0.70-1.10 | 0.30-0.60 | 0.20-0.45 | 0.025 | 0.025 |

Mechanical Properties (After Heat Treatment)

-

Tensile Strength: 980-1180 MPa

-

Yield Strength: ≥ 835 MPa

-

Elongation: ≥ 14%

-

Reduction of Area: ≥ 50%

-

Impact Energy (Charpy): ≥ 63 J

-

Surface Hardness (Post-Nitriding): 900-1000 HV

Heat Treatment

-

Normalizing: 870-900°C, air-cooled

-

Quenching: 930-950°C, oil-cooled

-

Tempering: 600-650°C, air-cooled (adjustable based on required hardness)

-

Nitriding: Recommended for achieving ultra-high surface hardness (e.g., gas nitriding at 500-530°C).

Key Applications

-

Precision gears, shafts, and spindles

-

High-wear components (e.g., cylinder liners, piston rods)

-

Injection molds and tooling requiring nitrided surfaces

-

Aerospace and automotive high-strength fasteners

-

Hydraulic/pneumatic system components

Product Specifications

-

Diameter Range: 10 mm – 300 mm (custom sizes available)

-

Length: 3,000 mm – 6,000 mm (cut-to-length service provided)

-

Surface Condition: Black, polished, or precision machined (as per request)

-

Tolerances: DIN h9/h11 or customized

Packaging & Delivery

-

Standard Packaging: Anti-rust oil coating + waterproof paper + wooden crates

-

Certification: Mill test certificates (EN 10204 3.1/3.2) provided

-

MOQ: 1 ton (smaller trial orders negotiable)

Quality Assurance

-

Full traceability with heat number identification.

-

Compliance with ISO 683-3, ASTM A29, and DIN EN 10083-3 standards.

-

Ultrasonic testing (UT) and magnetic particle inspection (MPI) available.

Notes:

-

Custom heat treatment and machining services (e.g., turning, grinding) are available.

-

Technical support for nitriding process optimization provided.

![]()

![]()

![]()

![]()