-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

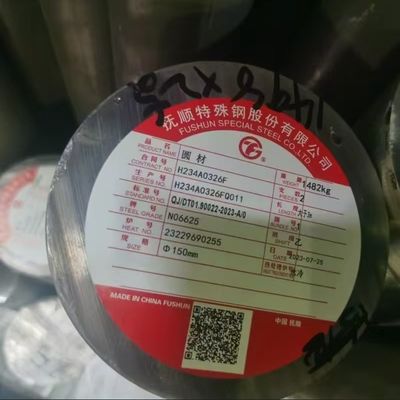

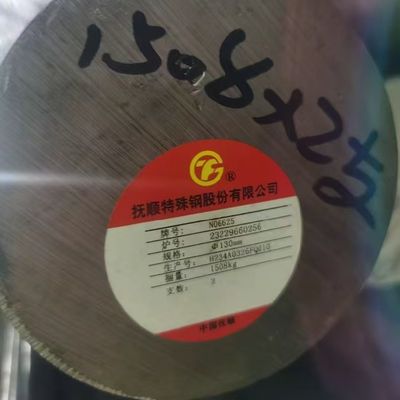

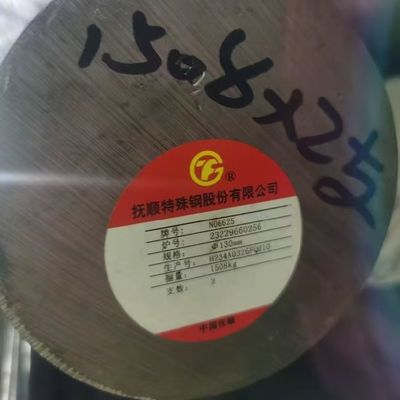

UNS N06625 Inconel Nickel Alloy Round Bar Alloy 625 Rod Diameter 20 - 150mm In Stock

| Products | Nickel Alloy Round Bar | Grade | Inconel 625 |

|---|---|---|---|

| Diameter | 10 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | Alloy 625 Round Bar,Alloy 625 Rod,Inconel Nickel Alloy Round Bar |

||

UNS N06625 Inconel Nickel Alloy Round Bar Alloy 625 Rod Diameter 20 - 150mm in Stock

Products Specification

|

Name

|

Incoloy Alloy Bar

|

|||

|

Grade

|

Hastelloy

|

Hastelloy C-276(C-4 /C-200 /C-22 /B-3 /B-2 ),Hastelloy-X ,HastelloyR-135

|

||

|

Monel Alloy

|

Monel400 Monel401 Monel404 Monel K500

|

|||

|

Inconel alloy

|

Inconel 600/N06600 , Inconel 601/N06601/2.4851 , Inconel625/N06625 690/N06690 ,Inconel 718/N07718/GH4169 , X-750/N07750/GH4145

|

|||

|

Incoloy alloy

|

Incoloy 800/N08800 , Incoloy 800H/N08810 ,Incoloy 800HT/N08811 , Incoloy 825/N08825/2.4858, Incoloy901/GH2901 ,Incoloy 903/GH2903 , Incoloy 925 ,Incoloy 926/N08926/1.4529

|

|||

|

Nimonic alloy

|

Nimonic80A /GH4080A , Nimonic90 /GH4090

|

|||

|

Udimet alloy

|

Udimet500 /GH4500 , Udimet A286 /GH2132

|

|||

|

Alloy 20

|

alloy20cb3 /N08020 , alloy20 alloy28 /N08028 , NS1403

|

|||

|

Size

|

Sheet

|

δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

|

||

|

Strip

|

0.05*5.0-5.0*250mm

|

|||

|

Pipe

|

φ6-273mm;δ1-30mm;Length 1000-8000mm

|

|||

|

Bar

|

φ4-50mm;Length 2000-5000mm

|

|||

|

Wire

|

0.01-10mm

|

|||

|

Standard

|

Sheet/Strip

|

Pipe

|

Bar

|

Wire

|

|

AMS 5542

AMS 5598 |

ASTM B637

|

ASTM B637

|

AMS 5698

AMS 5699 |

|

|

Density

|

8.0 g/cm³

|

|||

|

Melting point

|

1350-1400 °C

|

|||

Inconel 625 round rod introduction

Inconel 625 is a nickel-based superalloy known for its excellent corrosion resistance, high strength and good mechanical properties at high temperatures. It is widely used in aerospace, chemical, ocean engineering and energy fields.

Main parameter of Inconel 625 Round Bar

Chemical composition (typical value) :

- Nickel (Ni): ≥58%

- Chromium (Cr): 20-23%

- Molybdenum (Mo): 8-10%

- Niobium (Nb): 3.15-4.15%

- Iron (Fe): ≤5%

- Carbon (C): ≤0.10%

- Manganese (Mn): ≤0.50%

- Silicon (Si): ≤0.50%

- Phosphorus (P): ≤0.015%

- Sulfur (S): ≤0.015%

Mechanical properties (room temperature) :

- Tensile strength: ≥830 MPa

- Yield strength: ≥414 MPa

- Elongation: ≥30%

- Hardness: ≤90 HRB

- Physical properties:

- Density: 8.44 g/cm³

- Melting point: 1290-1350°C

- Coefficient of thermal expansion: 12.8μm /m·°C (20-100°C)

- Thermal conductivity: 9.8 W/m·K (20°C)

Specification of Inconel 625 Round Bar

- Diameter range: usually 5mm to 300mm (can be customized)

- Length: The standard length is 3000mm or 6000mm, and can also be customized according to customer requirements.

Standard of Inconel 625 Round Bar

Inconel 625 round rods are produced and tested in accordance with the following international standards:

- ASTM B446: Standard for Nickel-Chrome-Molybdenum-niobium alloy bars

- AMS 5666: Specification for Aerospace materials

- EN 10095: European standard for superalloys

- GB/T 15007: China standard for corrosion resistant alloys

Peculiarity of Inconel 625 Round Bar

- Excellent corrosion resistance: Excellent performance in both oxidizing and reducing environments, resistance to pitting, crevice corrosion and stress corrosion cracking.

- High temperature performance: maintain good mechanical properties and oxidation resistance at high temperatures.

- High strength: High strength is achieved by solution strengthening and precipitation hardening.

- Good weldability: suitable for a variety of welding processes, stable performance after welding.

Advantage of Inconel 625 Round Bar

- Versatility: Suitable for extreme environments such as high temperature, high pressure and highly corrosive media.

- Long life: Long-term stability in harsh conditions, reducing maintenance and replacement costs.

- Wide applicability: can be used in a variety of industrial fields to meet the needs of complex working conditions.

Similar Grade of Inconel 625 Round Bar

- USA: UNS N06625

- Europe: 2.4856 (EN)

- Germany: NiCr22Mo9Nb (Werkstoff Nr.)

- Japan: NCF625 (JIS)

- China: NS3306 (GB/T 15007)

Application of Inconel 625 Round Bar

Inconel 625 round rods are widely used in the following areas:

- Aerospace: Engine components, combustion chambers, turbine blades.

- Chemical industry: reactor, heat exchanger, pipeline system.

- Marine engineering: seawater treatment equipment, submarine parts.

- Energy: Nuclear reactor components, gas turbines.

- Oil and gas: downhole tools, valves, pump components.

- Other: high temperature furnace components, heat exchangers, fasteners.

Inconel 625 round rods, with their excellent performance and wide range of applications, are the ideal material for high temperature, corrosive environments. Its high strength, corrosion resistance and good processing properties make it an important position in a number of industries.

![]()

![]()

![]()

![]()