-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

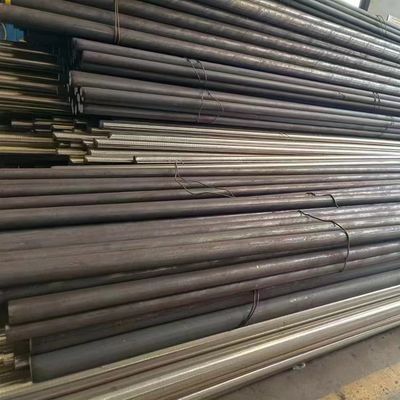

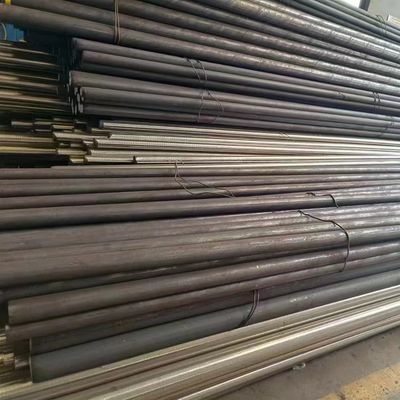

GH2132 Alloy Round Bar Nickel - Chrome Alloy Heat Resistant Rod Diameter 6 - 300mm

| Products | Nickel Alloy Bars | Grade | GH2132 |

|---|---|---|---|

| Diameter | 6 - 300mm | Length | 6000mm Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | Nickel Chrome Alloy Round Bar,Heat Resistant Alloy Round Bar,GH2132 Alloy Round Bar |

||

GH2132 Alloy Round Bar Nickel - Chrome Alloy Heat Resistant Rod Diameter 6 - 300mm

| Form | Nickel Alloy Bars |

| Grade | GH2132 |

| Outer Diameter | 6mm-300mm or according to customer’s requirement |

| Length | custom cutting any length as request |

| Standard | ASTM, ASME, EN, JIS, DIN, GB/T, etc |

| Process Method | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar & Rod |

| Surface Finish | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Other Grade |

Hastelloy : B2 B3 C22 C276 G30 X Incoloy: 800 800H 800HT 825 925 A286 330 Inconel: 600 601 617 625 718 725 X-750 Monel: 400 k-500 |

| Price Item | EXW FOB CFR CIF |

| Payment | 30% TT inadvance, 70% TT Balance against copy of B/L |

| Delivery Time | It depends on your bars order total quantity and stock of these mother origin materials. Usually from the start of the order to the completion of production is about 3-4 weeks |

| Quality Requirement | Mill test certificate will be offered with shipment, the third party inspection is available |

| Main Markets | Europe, North America, Middle East, Southeast Asia |

| Metal Test | High or low temperature impact test, metallographic analysis |

| Chemical Analysis | As nickel alloy 718 bars standard |

Our Service

- Cutting: custom cutting our bars into any length as request

- Polishing: Bright polishing , cold drawn finishing

- Heat Treatment: Solid Solution , aging, Q+T

GH2132 is a high-temperature alloy with iron (Fe), nickel (Ni) and chromium (Cr) as the main components, and its specific chemical composition is Fe-25Ni-15Cr, which is synthesized and strengthened by the addition of molybdenum (Mo), titanium (Ti), aluminum (Al), vanadium (V), and trace boron (B). The alloy has high strength and excellent corrosion resistance at room temperature, and exhibits high yield strength and long-lasting creep strength at high temperatures, up to a maximum service temperature of 650°C. The alloy is also available in a wide range of materials, including aluminum, titanium, aluminum (Ti), vanadium (V), and trace boron (B).

Chemical Composition

The main chemical composition of GH2132 alloy includes:

- Nickel (Ni): about 24.0-27.0%

- Chromium (Cr): about 13.5-16%

- Molybdenum (Mo): about 24%

- Iron (Fe): about 3%

Other trace elements: such as titanium (Ti), aluminum (Al), vanadium (V) and trace boron (B), etc.In addition, other elements such as manganese, silicon, cobalt and vanadium may be present.

The Effect Of The Chemical Composition Of GH2132 Alloy

- GH2132 alloy has high yield strength and enduring, creep strength below 650°C. This is mainly attributed to its complex microstructure, including uniformly distributed diffuse phases and solid solutions. In particular, the precipitation strengthening of the γ’-Ni3(Ti, Al) phase allows the alloy to exhibit excellent mechanical properties at elevated temperatures.

- The presence of chromium (Cr) confers good corrosion resistance to GH2132 alloy, enabling it to operate stably in high temperature and corrosive environments.

- GH2132 alloy has good machining plasticity and satisfactory weldability, thanks to its comprehensively strengthened design, including added elements such as molybdenum, titanium, aluminum, vanadium and trace boron.

- In terms of mechanical properties, GH2132 alloy has a tensile strength of 115-234 MPa, a yield strength of 23 MPa, a ductility of 65%, an HBS grade of 123-321 and an HRC grade of 30

The HBS grade is 123-321, and the HRC grade is 30.

Application Cases In Aero-Engine Component Manufacturing

1.Turbine disks

GH2132 alloy is widely used in the manufacture of turbine disks for aero-engines due to its excellent high temperature strength and creep resistance. These components are required to operate at high temperatures for long periods of time and therefore require extremely high material properties.

2.Compressor disks

The alloy is also used in the manufacture of compressor disks for aero-engines, which also need to withstand high temperatures and high rotational mechanical loads.

3.Fasteners

GH2132 alloy is also used in the manufacture of various types of fasteners for aero-engines, which work at high temperatures and pressures, and have high requirements for corrosion resistance and mechanical strength.

4.Load bearing rings and magazines

In addition, GH2132 alloy is also used in the manufacture of aero-engine load bearing rings and magazines and other components, which also need to have good high-temperature performance and mechanical strength.

5.Shafts and plate welded bearings

GH2132 alloy is also used in the manufacture of aero-engine shafts and plate welded bearings, which need to maintain high stability and reliability when working in high temperature environments.

6.Charge chamber

In addition to the above components, GH2132 alloy is also used in the manufacture of aero-engine charge chambers, which are also required to work in high temperature environments and require good oxidation resistance and high-temperature strength.

Advantages

1.High-temperature performance

GH2132 alloy has extremely high yield strength and long-lasting, creep strength below 650°C, which makes it able to maintain good mechanical properties in a high-temperature environment, and is suitable for components such as aero-engines, etc., that need to work at high temperatures for long periods of time.

2.Machining plasticity

GH2132 alloy has excellent machining plasticity, which means that it performs well in hot and cold machining and molding processes, and is able to meet the manufacturing needs of complex parts.

3.Weldability

The alloy also has satisfactory weldability, which makes it easy to weld to other materials or to itself during the manufacturing process, thus increasing the reliability of the overall structure.

4.Wide range of applications

Due to its excellent high-temperature performance and good processability, GH2132 alloy is particularly suitable for the manufacture of high-temperature load-bearing components in aero-engines, such as turbine disks, compressor disks, rotor blades and fasteners

![]()

![]()

![]()

![]()