-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

ASTM EN DIN Stainless Steel Plates Sheet Hot Rolled 254SMO For Boiler And Pressure Vessel

| Products Name | Stainless Steel Checkered Plate | Grade | 254SMO |

|---|---|---|---|

| Thickness | 0.6-30.0mm | Standard | ASTM EN GB |

| Width | 1000mm 1219mm 1500mm | Surface | 2B NO.1 |

| Brand | TISCO BAOSTEEL | MOQ | 1 Ton |

| Highlight | Hot Rolled Stainless Steel Plates Sheet,Boiler Stainless Steel Plates Sheet,Pressure Vessel Stainless Steel Plates Sheet |

||

ASTM EN DIN Stainless Steel Plates Sheet Hot Rolled 254SMO For Boiler and Pressure Vessel

| Item | 254SMO Stainless Steel Plate |

| Raw Material | Stainless steel sheet (hot rolled and cold rolled) |

| Grades | 201, 202, 301, 304, 304L, 310S, 309S, 316, 316L, 321, 409L, 410, 410S, 420, 430, 904L, 2205 ,2507,254SMO,253MA.etc. |

| Thickness | 0.6 - 30.0mm |

| Stock Thickness | 0.6mm ,0.8mm,1.0mm,1.2mm,1.5mm.2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 5.5mm, 6mm, 7mm, 8mm,10.0mm,12.0mm,14.0mm,16.0mm,20.0mm,25mm,30.0mm |

| Width | 1000mm 1219mm 1500mm or cutting any size as your request |

| Finish | 2B, BA, No. 1, No. 4, mirror, brush, hairline, chequered, embossed, etc. |

| Package | Standard export package |

S31254 F44 1.4547 254SMo two-phase stainless steel overview:

High molybdenum content and high chromium and nitrogen content make the 254SMO have excellent resistance to spot corrosion and crevice corrosion.The addition of copper improves corrosion resistance in some acids.In addition, due to its high nickel content and high chromium and molybdenum content, the 254SMO has good stress corrosion cracking resistance.Numerous field tests and extensive use have shown that, even at slightly higher temperatures, the 254SMO is highly crevices resistant in seawater, and only a few types of stainless steels have this property.The corrosion resistance of the 254SMO in acidic solutions and oxidized halide solutions required for bleaching processes such as paper is comparable to that of the most corrosion-resistant nickel-based and titanium alloys.Due to its high nitrogen content, the mechanical strength of the 254SMO is higher than that of other types of austenitic stainless steels.In addition, the 254SMO has high ductility and impact strength as well as good weldability.The high molybdenum content of the 254SMO allows it to have a higher oxidation rate when annealed, thus having a rougher surface than ordinary stainless steel after pickling.But this has no adverse effect on the corrosion resistance of the steel.

S31254 F44 1.4547 254SMo Chemical composition of stainless steel

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | N≤ |

| 0.02 | 0.80 | 1.00 | 0.03 | 0.01 | 19.5-20.5 | 4.5-6.5 | 6.0-6.5 | 0.18-0.22 |

Metallographic structure of 254SMO:The 254SMO is a face-centered cubic lattice structure.In order to obtain austenite structure, the 254SMO is normally annealed at temperatures of 1150 to 1200 degrees Celsius.In some cases, the center of the material may have traces of metal mesophase.But in general, they have no adverse impact on impact strength and corrosion resistance.These phases may precipitate at grain boundaries when placed at temperatures between 600 and 1000 degrees Celsius.

S31254 F44 1.4547 254SMo two-phase stainless steel corrosion resistance:

The carbon content of the 254SMO is very low, which means that there is little risk of carbide precipitation from heating.The steel can pass the Strauss Test ASTMA262 specification E, even after being sensitized for one hour at 600-1000 degrees Celsius.However, due to the high alloy content of the steel.Metal mesophase may precipitate at grain boundary in the above temperature range.These deposits do not present the risk of intergranular corrosion of the steel when used in corrosive media.Therefore it can be welded without intercrystalline corrosion.But in hot concentrated, these deposits may cause intercrystalline corrosion in the heat affected zone.In solutions containing chloride, bromide, or iodide, ordinary stainless steels are immediately subjected to local corrosion in the form of pitting corrosion, crevice corrosion, or stress corrosion cracking.However, in some cases, the presence of halides accelerates uniform corrosion.This is especially true in the presence of halides in non-oxidizing acids.In pure sulfuric acid, 254SMO has much greater corrosion resistance than 316 normal stainless steel.However, compared with type 904L (NO8904) stainless steel at high concentration, the corrosion resistance of type 254SMO is slightly weaker.In sulfuric acid containing chloride ions, 254SMO has the largest corrosion resistance.Due to the possibility of local and uniform corrosion, 316 ordinary stainless steel cannot be used in hydrochloric acid, but 254SMO can be used in diluted hydrochloric acid at normal temperature.There is no need to worry about pitting below the boundary.But try to avoid gaps.In fluorosilicic acid (H2SiF4) and hydrofluoric acid (HF), the corrosion resistance of ordinary stainless steel is very limited, while the 254SMO can be used over a wide range of concentrations and temperatures.

Our Processing Service

- Surface Finishing: Mirror Polishing, Hairline Finishing, SB , NO.4, Santi Finishing, Anti-finger Print, PVC film Cover, Titunam Colored , checkered Finishing

- Cutting Service : Laser Cutting, waterjet cutting, plasma Cutting, machine Cutting. Slit cutting

- Bending Service: bending range thickness within 30mm

- Welding Service: any kinds of welding process

Packing Detail

- PACKING INFORMATIONS FOR SHEETS:

1, Type 1, wooden pallets and waterproof paper

2, Type 2, wooden pallets and waterproof paper + steel corner

3, Type 3, wooden pallets and waterproof paper + steel corner + wooden plates cover

4, Type 4, wooden box

* Each packing loading about 1.5 - 2 Tons

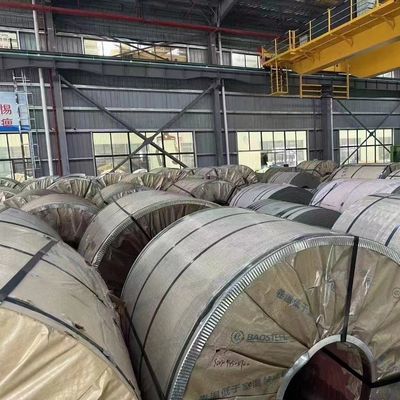

- PACKING INFORMATIONS FOR COILS

The coils and strips will loading on the # shape wooden frame.

Surface of the coils or strips will cover by waterproof paper and plastic film

*Each frame loading within 6 Tons

![]()

![]()

![]()

![]()