-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

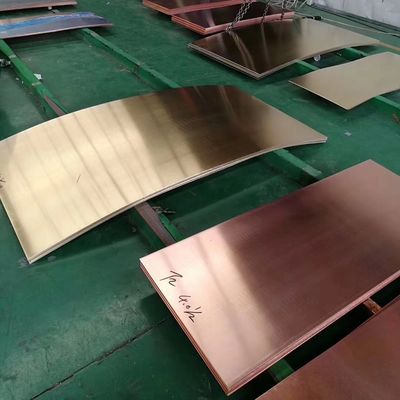

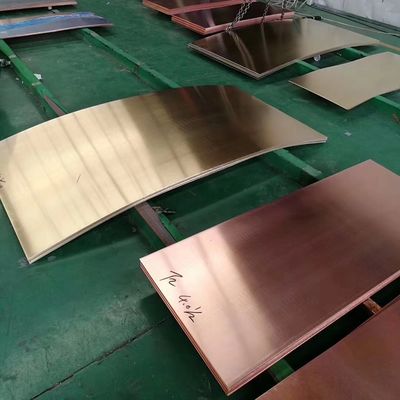

99.9% Pure Copper Plate Thickness 1.0 - 200mm Custom Cutting Any Size C11000 Copper

| Products | Copper Flta Bar | Grade | C11000 / T2 |

|---|---|---|---|

| Standard | ASTM GB EN DIN JIS | Thickness | 0.5 - 60.0mm |

| Width | Within 1000mm | Length | 6m Or Custom As Request |

| Certificate | EN 10204-3.1 | Other Products | Pipe , Round Bar, Strips |

| Highlight | Any Size 99.9% Pure Copper Plate,Custom Cutting 99.9% Pure Copper Plate,200mm 99.9% Pure Copper Plate |

||

99.9% Pure Copper Plate Thickness 1.0 - 200mm Custom Cutting Any Size C11000 Copper

|

Product name

|

Copper Plate & Sheet |

| Copper and copper alloy grade |

C11000,C10100,C12200

H59, H60, H62, H65, H68, H70, H80, H85, H90, H96, C2100, C2200,C2300, C2400, C2600, C2680, C2720, C2800, C3560, C3601, C3713, C3771, C3561 , CuZn30, CuZn32, CuZn35, CuZn37, CuZn40 ,TU1, T2, TP2, H96, H90, H85, H80, H70, H65, H63, H62, H59, HPb63-3, HPb66-0.5, HPb62-2, HPb62-3, HPb59-3, HSn70-1, HSn62-1,QSn8-0.3, QSn4-4-4, QAl9-4, QSB-1 etc.

|

| Width | Within 1500mm Custom Cutting any width as request |

| Thickness | 0.5 - 200.0mm |

|

Length |

1m 2m 3m 6m or custom cutting any length as request |

| Standard | ASTM EN DIN JIS GB |

| Other products | Plate, Sheet, Coil , Pipe, Round Bar, Square Bar, Flat Bar, Hexagonal Bar.etc |

Copper Alloy 110/C110/C11000 Electrolytic Tough Pitch (ETP)

Copper Alloy 110/C110/C1100 Electrolytic Tough Pitch (ETP) is a very pure alloy of copper (99.9% min. cu). It is a versatile alloy because of its resistance to corrosion, high electrical and thermal conductivity, and its aesthetic quality. It is used for a variety of projects and applications including construction, DIY, arts and craft projects, rfi shielding, manufacturing, electrical applications, research and development and much more.

C110 Data Specifications – Manufactured to ASTM B152 (Certification of Conformance Provided upon Request)

C11000 electrolytic tough pitch copper, or ETP copper, is produced by the direct conversion of selected refined cathodes and castings under carefully controlled conditions. C11000 electrolytic copper has inherent fabrication qualities that readily allow it to be bent, soldered, drilled, welded, and formed to fit almost any design specification.

ETP Copper is the most commonly used copper, since it’s universal for electrical applications. C11000 has a minimum conductivity rating of 100% and is required to be 99.9% pure. C11000 copper alloys have several applications and are readily available through several US copper suppliers in sheet and bar form.

C11000 copper is mostly used for buss bar as well as electrical and electronic conductors. It’s chemical composition is 99.9% copper. The density of this electrolytic copper alloy is 8.89 grams per cubic centimeter. The melting point of C11000 is 1065 to 1083 degrees Celsius.

Chemical Properties

- Copper-99.9% (min.)

- Oxygen-0.05% (max.)

Physical Properties

- Density: lb/cu in. at 68F-0.322

- Thermal Conductivity: 226 BTU- /sq.ft./hr/°F

- Electrical Resistivity: 10.3 ohm circ mils/ft

- Electrical Conductivity: (annealed) 101% IACS

- Modulus of Elasticity: 17,000,000 psi

- Coeff of Thermal Expansion: 68-572 Fahrenheit | 9.8PPM/Fahrenheit

Mechanical Properties

| Tensile Strength | Yield Strenth1 | Elongation2 | |

|---|---|---|---|

| Temper-Annealed | 26 to 38 ksi | 6 to 13 x 1000 psi | 20-50 |

- Annealing: This alloy can be annealed between 700 and 1200 degrees Fahrenheit

- Hot Treatment: 1400-1600 Fahrenheit

- Melting Point (approx.): 1981 Fahrenheit

Fabrication Information

- Soldering: Excellent

- Brazing: Good

- Oxyacetylene Welding: Not Recommended

- Gas Shielded Arc Welding: Fair

- Coated Metal Arc Welding: Not Recommended

- Spot Weld: Not Recommended

- Seam Weld: Not Recommended

- Butt Weld: Good

- Cold worked capability: Excellent

- Hot Formed Capability: Excellent

- Forgeability Rating: 65

- Machinability Rating: 20

Applications of Electrolytic Copper

- Welding fixtures

- Anodes

- Bus bar in electrical power installations

- Ground straps

- Automotive rectifiers

- Inductors

- Glass to metal seals

- High resistance ratio cryogenic shunts

- Lean-in wire seals

- Transistor component bases

- Bus conductors

- Wave guides

- Hollow conductors

- Anodes

Fabrication Properties

The fabrication properties of C11000 include:

- Machining

- The machinability rating of C11000 is 20%.

- Welding

- Soldering, brazing, gas shielded arc welding, oxyacetylene welding and butt welding are recommended for C11000 copper. Other welding techniques such as coated metal arc welding, spot welding and seam welding are not recommended.

- Forging

- C11000 copper is forged at hot working temperatures from 760 to 871 degrees Celsius. The hot forgeability rate of this metal is 65%.

- Hot working

- C11000 copper has excellent hot working property.

- Cold working

- C11000 copper has excellent cold working property.

- Annealing

- Annealing C11000 occur at temperatures from 371 to 648 degrees Celsius.

Corrosion Resistance

One of the most unique properties of C11000 copper alloys is its resistance to corrosion.

C11000 has excellent corrosion resistance to weathering and very good resistance to many chemicals. This copper alloy is suitable for use with most waters and can be used underground because it resists soil corrosion. C11000 also resists non-oxidizing mineral and organic acids, caustic solutions and saline solutions.

Copper generally resists:

- Mineral acids

- Organic acids

- Carbolic, citric, Formica, oxalic, tartaric, and fatty acids

- Solutions constraint sulfur

- Solutions used in pulp mills

- Alkaline fused with sodium

- Salt solutions

- Water, all potable waters

Copper generally does not resist:

- Ammonia

- Oxidizing acids

- Acetic acids

- Mercury and mercury salts

![]()

![]()

![]()

![]()