-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

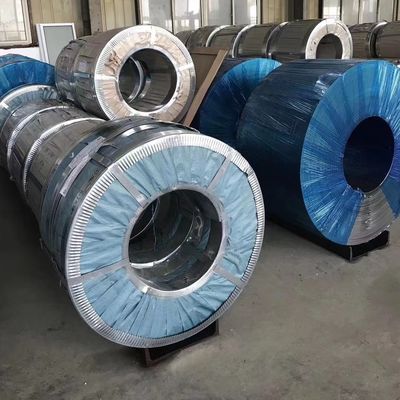

Cold Rolled 50Mn 65Mn 40Mn Steel Strips High Hardness Spring Steel Strip Roll

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | SK5 SK4 SK2 65Mn 45Mn 40Mn 15CrMo 20Cr 40 Cr 10# 20# 35# 45# 50# 60# CK75 SPHC SPCC Q195-355 ST12 ST14 .etc |

| Minimum Order Quantity | 4 Ton |

| Price | 625-870 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Spring Steel Strip | Thickness | 0.3 - 3.0mm |

|---|---|---|---|

| Width | 1000mm 1250mm Or As Request | Surface | Regular Spangle, Zero Spangle |

| Packing | Wooden Pallets And Waterproof Paper | Brand | BAOSTEEL ANSTEEL |

| Service | Cutting | Coil ID | 508mm |

| Highlight | Roll Spring Steel Strip,High Hardness Spring Steel Strip,65Mn Spring Steel Strip |

||

Cold Rolled 50Mn 65Mn 40Mn Steel Strips High Hardness Spring Steel Strip Roll

Specification of our products

|

Standard

|

Steel Strips

|

|

Steel Grade

|

65Mn / AISI 1066 / 080A67

|

|

Application

|

Spring Steel

|

|

Brand Name

|

Delta

|

|

Width

|

within 1250mm |

|

Tolerance

|

±1%

|

|

Thickness

|

0.3 - 3.0mm as request

|

|

Other Material

|

SK5 SK4 SK2 65Mn 45Mn 40Mn 15CrMo 20Cr 40 Cr 10# 20# 35# 45# 50# 60# CK75 SPHC SPCC Q195-355 ST12 ST14 .etc

|

|

Standard

|

ASTM EN JIS GB DIN

|

|

Type

|

Strip

|

|

Technology

|

Cold Rolled

|

65Mn is high carbon steel with plenty of uses that’s also prominent in the knife industry. It’s Chinese-made steel with a good balance of hardness and toughness.

65Mn steel’s toughness is excellent for shock absorbers, machetes, swords, and any other tool that requires resilience. Being this tough, it would come to mind that 65Mn steel is only for making cleavers and similarly purposed knives, but such a conclusion would be wrong.

Knifemakers can use 65Mn steel to forge any type of knife. Nonetheless, it’s primarily chosen by knife brands to make large blades, like machetes, swords, and sizable chefs’ knives.

Here is everything you need to know about 65Mn steel, from its chemical composition to its properties and traits it can give to a knife and more.

65Mn composition

- Carbon (C): 0.60 – 0.70%

- Chromium (Cr): 0.25%

- Manganese (Mn): 1.10 – 1.20%

- Silicon (Si): 0.15 – 0.40%

- Nickel (Ni): 0.35%

- Copper (Cu): 0.25%

Guide For Ordering Products

A user need provide the following information while placing order

01.Product designation

02.Product standard number

03.Steel grade

04.Product specification and size accuracy (incl. thickness, width and length)

05.Edge status

06.Surface quality level

07.Flatness accuracy

08.Type, coating weight and surface treatment in case of coated products

09.Surface structure in case of hot dip galvanized products

10.Weight

11.Packing method

12.Application

13.Other special requirements

FAQ