-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

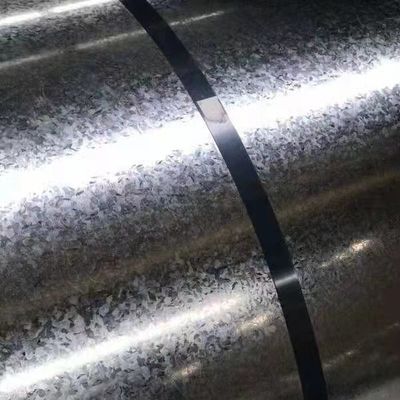

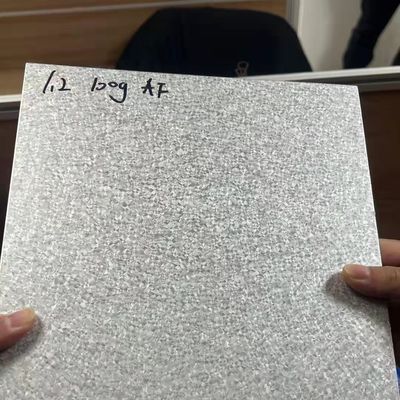

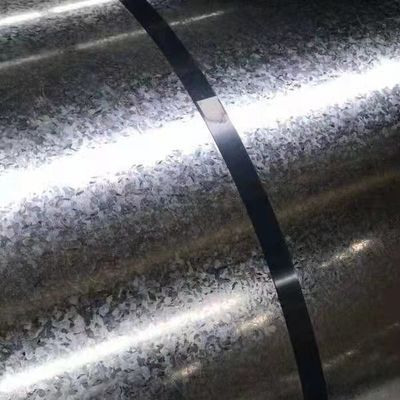

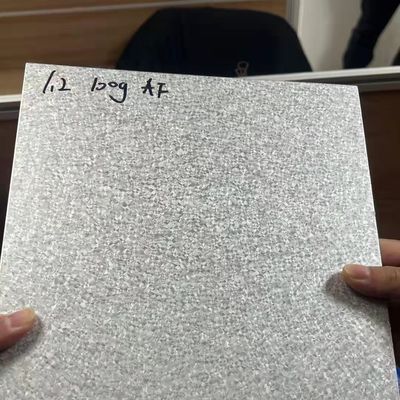

508mm 610mm Galvanized Steel Coil Z30-Z275 DX51D 0.3-3.0mm

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL WISCO |

| Certification | ISO |

| Model Number | DX51D SGCC |

| Minimum Order Quantity | 2 Ton |

| Price | 600-860 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Galvanized Steel Coil | Thickness | 0.3-3.0mm |

|---|---|---|---|

| Width | 1000mm 1250mm 1500mm Or As Request | Surface | Regular Spangle, Zero Spangle |

| Zinc Coating | Z40 - Z275 | Brand | BAOSTEEL ANSTEEL |

| Service | Cutting | Coil ID | 508mm |

| Highlight | 610mm Galvanized Steel Coil,508mm Galvanized Steel Coil,3.0mm galvanized coil |

||

Inner Diameter 508mm 610mm Galvanized Steel Coil Z30 - Z275 Galvanized Coil DX51D

Specification of our products

| Products Name | Galvanized Steel Sheet / Galvalume Steel Sheet / Prepainted Galvanized Steel Sheet |

| Thickness | Galvanized steel sheet 0.12 - 3.0mm Thickness |

| Galvalume Steel Sheet 0.25 - 3.0mm Thickness | |

| Prepainted Galvanized Steel Sheet 0.12 - 1.2mm Thickness | |

| Width | 914mm,1000mm,1200mm,1219mm,1220mm,1250mm Or According To Customer's Requirement |

| Length | Custom length as customer requirement |

| Coil Weight | 2Ton - 8 Tons |

| Coil Inner Diameter | 508mm or 610mm |

| Surface | Galvanized steel sheet: Regular spangle / non-spangle Zinc: Z30 - Z275 |

| Galvalume Steel Sheet : AZ40 - AZ180 | |

| Prepainted Galvanized Steel Sheet:Painting Type:PE,HDP,SMP,PVDF | |

| Standard | AISI, ASTM, BS, DIN, GB, JIS, AS ETC |

Galvanised steel is represented by cold- and hot-rolled coils with a zinc coating, which helps to protect the steel against atmospheric corrosion. Galvanised steel coils are successfully used in industries with stringent requirements for corrosion resistance, durability, strength and appearance, and can be formed or have various coatings applied. The key standards to be followed for the production of galvanised coils include EN 10346 (Europe), ASTM A653 / A653M (US)

Application of galvanised steel coils

Galvanised steel coils are widely used in the following industries:

-

In the construction industry: to manufacture structural elements low-rise construction, light steel thin-walled structures, sandwich panels, lining of heat pipelines and various heat insulation, conditioning systems, metal roof shingle, profiled sheeting, culvert pipes, cladding of entry doors, elevators, reinforcement profiles for PVC windows and plastic doors, European-type fasteners for plasterboards, etc

-

In the automotive industry: to manufacture external and internal car body parts, as well as to repair external public transport body parts, eg for buses and trams)

-

In the machine building and instrumentation industries: to manufacture cases for electrical and mechanical equipment, home appliances, metering devices and packing

-

To manufacture houseware (tableware, bowls, buckets, tanks, baths, etc)

-

To manufacture colour-coated (and other type of coating) rolled steel

hot dipped galvanized steel coil classification, product range and properties

Standards applied in different countries to set the requirements for galvanized steel coils specify steel grade and size ranges for these products. Galvanised steel coils are classified based on the following features:

-

Application of coated steel (profiling, cold forming, manufacture of steel structures)

-

Chemical composition of coating material (pure zinc, zinc-iron/zinc-aluminium/aluminium-zinc/zinc-magnesium alloys, etc)

-

Thickness/weight of protective coating

Galvanised steel coils

-

Types of surface quality:

-

А – surface quality right after coating application

-

В – surface quality improved by processing in a skin pass mill

-

С – highest surface quality also obtained by processing in a skin pass mill; the controlled surface should allow for the application of a homogeneous layer of decorative paint, while the other surface should have minimum quality B

Surface treatment:

-

Chemically passivated – С

-

Oiled – О

-

Passivated and oiled – СО

-

Phosphate treated – Р

-

Coated with organic insulation – S

-

-

Surface finishing:

-

Standard spangle pattern (normal gloss) N is obtained by allowing zinc coating to harden naturally

-

Minimum spangle pattern (minimum gloss) M is obtained by adjusting molten zinc composition and special measures for hardening and/or subsequent surface finishing

-

-

Geometry and size tolerances for steel sheets and strip coated by hot dipping should meet the requirements of the European EN 10143 standard and its Ukrainian analogue DSTU EN 10143.

Production of galvanized steel coils

There are two widely used methods for applying zinc coating on steel coils:

![]()

![]()

![]()

![]()

-

Hot-dip galvanising (HDG) technology is used to create a protective layer by immersing a steel strip into a bath of molten zinc. Hot-dip galvanised steel coils can be produced by continuous galvanising lines with non-oxidising annealing furnaces (the Sendzimir method and its variations) or by applying wet or dry flux (the Cook-Norteman method and its modifications). Hot- or cold-rolled non-annealed (full-hard) steel coils are used as feedstock for continuous hot-dip galvanising lines with non-oxidising annealing furnaces. The production process involves electrochemically cleaning, drying and annealing the strip to obtain the required mechanical properties, followed by immersing the material into a bath of molten zinc and controlling zinc thickness. The strip then undergoes forced cooling and finishing (passivation, oiling, levelling, drying and coiling the galvanized coil). When using lines that apply wet or dry flux, feedstock (before it is galvanized) should have the required set of mechanical properties since such lines do not have annealing furnaces. The strip is first degreased with an alkali solution and pickled in acid, following which a smooth layer of flux composed of a combination of zinc chloride, ammonia chloride and various additives is applied to the strip. The strip is then put into a strand furnace with a protective atmosphere, where the flux is dried, and is immersed into a bath of molten zinc. The flux completely removes residual pickling substances and moisture from the metal surface, and the thin film reduces the surface tension of zinc and ensures the best moistening of the metal surface. Hot-dip galvanising technology is fairly universal and is widely used in construction, machine building and other industries. It is used by both large steel mills and re-rollers/coaters.