-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

EN 1.4529 / 926 / UNS N08926Stainless Steel Plates Sheets and Coils Custom Cutting

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | EN 1.4529 / 926 |

| Minimum Order Quantity | 500 kgs |

| Price | 7.5-8.1 USD/Kg |

| Packaging Details | wooden pallets + waterproof paper |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Plates&Sheets | Grade | EN 1.4529 / 926 |

|---|---|---|---|

| Standard Size | 1000*2000mm 1219*2438mm 1500*6000mm | Thickness | 0.4- 40.0mm |

| Brand | TISCO BAOSTEEL POSCO LISCO | Loading Port | Shanghai Port |

| MOQ | 300 Kgs | Packing | Wooden Pallets + Waterproof Paper |

| Highlight | stainless steel flat plate,stainless flat plate,stainless flat sheet |

||

EN 1.4529 / 926 / UNS N08926Stainless Steel Plates Sheets and Coils Custom Cutting

Quick Informations

| Products Name | 1.46529 / 926 Stainless Steel Plate | Standard | ASTM EN DIN JIS GB |

| Thickness | 0.4 - 50.0mm | Surface | 2B NO.1 BA NO.4 8K |

| Standard Size | 1000*2000mm 1219*2438mm 1500*6000mm | Service | Cutting, surface processing |

More Informations of our Products

| Item | Stainless Steel Plates / Stainless Steel Sheets |

| Main Grades | 201, 202, 301, 304, 304L, 310S, 309S, 316, 316L, 321, 409L, 410, 410S, 420, 430, 904L, etc. |

| Thickness | 0.4mm-40mm |

| Stock Thickness | 0.4mm 0.5mm 0.6mm 0.8mm 1.0mm 1.2mm 1.5mm 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 5.5mm, 6mm, 7mm, 8mm,10mm,12 - 40mm |

| Width | 1000mm 1219mm 1500mm or cutting any size as request |

| Standard size | 1000*2000mm 1219*2438mm 1500*6000mm 2000*6000mm |

| Finish | 2B, BA, No. 1, No. 4, mirror, brush, hairline, chequered, embossed, etc. |

| Package | wooden pallets and waterproof paper |

EN 1.4529 stainless steel is a superaustenitic (highly alloyed) stainless steel formulated for primary forming into wrought products. Cited properties are appropriate for the solution annealed (AT) condition. 1.4529 is the EN numeric designation for this material. X1NiCrMoCuN25-20-7 is the EN chemical designation.

It has a moderately high tensile strength and a moderately high ductility among wrought superaustenitic stainless steels.

The graph bars on the material properties cards below compare EN 1.4529 stainless steel to: wrought superaustenitic stainless steels (top), all iron alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relevant set. A half-full bar means it's 50% of the highest, and so on.

Characteristics of Alloy 1.4529

1.4529 is characterized by:

- increased resistance to stress corrosion cracking compared to other austenitic stainless steels

- excellent general corrosion resistance in use of oxidizing as well as reducing media

- less tendency to form intermetallic phases compared to similar steels with only 18% nickel content

- very good resistance at pitting and crevice corrosion

- Approval for pressure vessels with temperatures between -196 and 400 ° C

- Building construction approval for components and fasteners made of stainless steel, German Institute of Structural Engineering, September '98

Equal Grade of 1.4529 Alloy

| Werkstoffnummer | 1.4529 |

| Alloy | Alloy 926 |

| Alloy 6XN | |

| EN short name | X1 NiCrMoCuN25-20-7 |

| UNS | UNS N08926 |

| UNS N08367 | |

| Registered Tradenames | SixMo® |

| Ultra 6XN® | |

| AL-6XN® | |

| Cronifer 1925hMo® | |

| Standards | EN 10028-7 |

| EN 10088-2 | |

| VdTÜV Werkblatt | 502 |

| ASTM / ASME | ASTM A240/ B688/ B625 |

| ASME SA24/ SB688/ SB625 |

Main fields of application of alloy 926

1.4529 is mainly in following applications:

- Concentration and crystallization plants for salt production by evaporation

- Condenser pipes and pipeline systems in power plants with highly polluted cooling water

- Pump rods for oil delivery systems

- Evaporators, heat exchangers, tank linings etc. and phosphoric acid production

- Tanks for transport of aggressive chemical products

- Distribution systems and coolers for sulfuric acid plants

- Fire extinguishing systems, seawater filtration, hydraulic and injection systems of offshore technology

- Flexible pipes in the offshore industry

Chemical composition of 1.4529 Stainless Steel

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N |

| 0-0.02 | 0-0.5 | 0-1.0 | 0-0.03 | 0-0.005 | 20,0-21,0 | 24.5-25.5 | 6.0-6.8 | 0.8-1.0 | 0.18-0.2 |

Hot forming

The material is hot formed within a temperature range of 1200 and 900 ° C and afterwards quenched rapidly in water or air.

The annealing takes place at 1200 ° C.

After hot forming, heat treatment for optimum corrosion resistance is recommended.

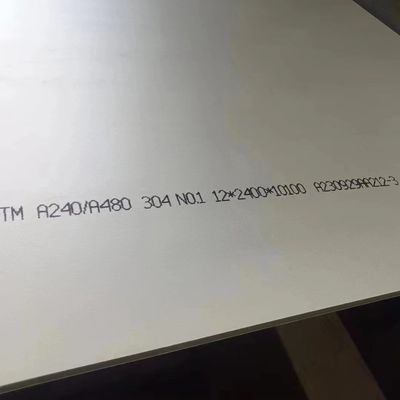

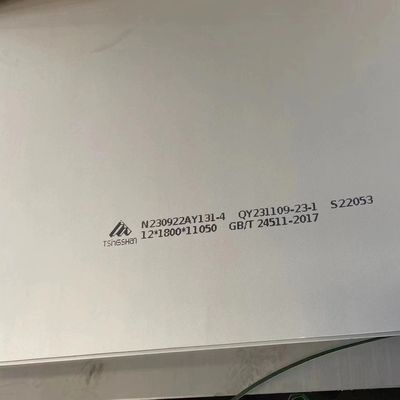

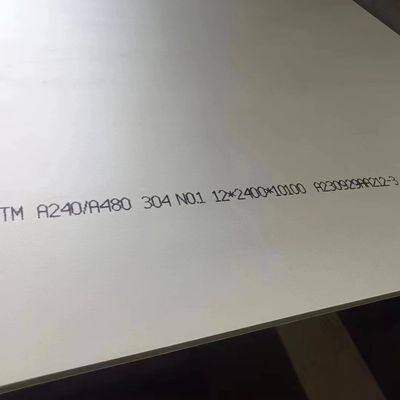

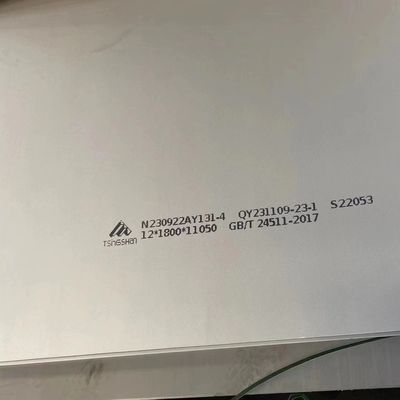

![]()

![]()

![]()

![]()