-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

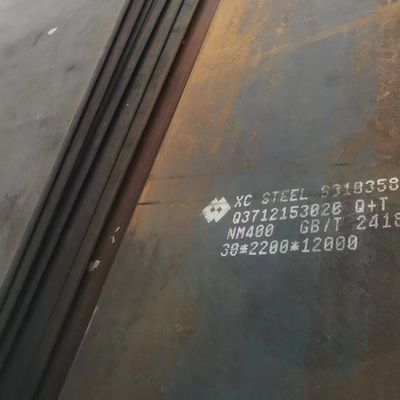

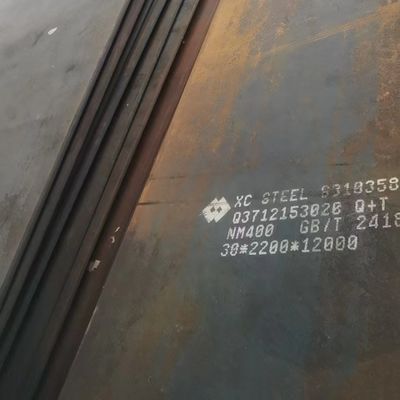

Abrasion-Resistant Steel Plate AR400 Thickness 3.0 - 40.0mm Width 1500mm 2000mm 2200mm

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL BENSTEEL HBIS XINGCHENG |

| Certification | ISO |

| Model Number | AR400 / Hardox 400 / NM400 |

| Minimum Order Quantity | 500 kgs |

| Price | 810 - 955 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Wear Resistant Steel Plate | Thickness | 4.0 - 40.0mm |

|---|---|---|---|

| Width | 1000-2200mm | Length | 2000-12000mm |

| Standard | ASTM EN GB | Other Grade | AR400 / AR450 / AR500 / AR600 |

| Brand | BAOSTEEL XINYU XINGCHENG HBIS | Service | Cutting |

| Highlight | abrasion resistant steel plate,wear resistant steel plate,wear resistant plate |

||

Abrasion-Resistant Steel Plate AR400 Thickness 3.0 - 40.0mm Width 1500mm 2000mm 2200mm

Products Specification of Wear Resistant Steel Plate

| Products Name | AR400 / NM400 Steel Plate |

| Thickness | 4.0 - 40.0mm |

| Width | 100 - 2200mm custom cutting any size as request |

| Length | 6m 8m 10m 11.5m 12m or cutting any length as request |

| Standard | ASTM JIS GB EN |

| MOQ | 500 Kgs |

| Deliver time | 7 - 14 days |

| Loading Port | Shanghai Port |

| Packing | wooden pallets |

| Other Grade | AR400 / AR450 / AR500 / AR600 NM400 NM450 NM500 NM600 |

| Service | Cutting, Heat treatment |

AR400 Steel Composition

AR400 steel is an abrasion-resistant steel with high levels of carbon and manganese. The carbon content provides strength and hardness, while the manganese improves ductility and toughness. In addition to these elements, AR400 steel may also contain small amounts of other alloys, such as nickel, chromium, or boron. These alloying elements can further improve the steel’s mechanical or physical properties.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | B |

| 400 AR | 0.25 | 0.7 | 1.70 | 0.025 | 0.015 | 1.50 | 0.70 | 0.5 | 0.005 |

AR400 Steel Mechanical Properties

AR400 steel is known for its exceptional mechanical properties, particularly its high tensile strength and hardness. Its tensile strength ranges from 155,000 to 180,000 psi, while its Brinell hardness ranges from 360 to 440, depending on the thickness of the steel. AR400 steel is also highly abrasion-resistant, making it ideal for applications that require resistance to wear and tear.

| Grade | Yield Strength MPa |

Tensile Strength MPa |

Elongation A |

Impact Strength Charpy V 20 J |

| 400 AR | 1000 | 1250 | 10 | -40°C |

AR400 Steel Physical Properties

In addition to its mechanical properties, AR400 steel also has some beneficial physical properties. It has a density of 7.85 grams per cubic centimetre and a low thermal expansion coefficient, which means it expands very little when exposed to heat. AR400 steel, with a moderate machinability rating, is also relatively easy to work with.

AR400 Steel Uses

AR400 steel is prevalent in many industries that require abrasion-resistant materials, such as construction, mining, and agriculture. It’s often used to make equipment and parts subject to frequent wear and tear, such as bulldozer blades, rock crushers, and drilling equipment. AR400 steel can also be used for structural applications, such as building frames, due to its strength and toughness.

AR400 Steel Corrosion Resistance

While AR400 steel is highly abrasion-resistant, it does not have excellent corrosion resistance. Without proper care, the steel can rust and corrode over time, especially if exposed to moisture or chemicals. Some manufacturers add a protective coating to their AR400 steel products or use stainless steel in highly corrosive environments to combat this.

AR400 Steel Heat Treatment

AR400 steel can be heat-treated to improve its mechanical properties even further. Tempering, for example, can help reduce the steel’s brittleness and improve its toughness. Quenching and tempering can increase the steel’s hardness, while annealing can improve its ductility and machinability. Trained professionals should only do heat treatment, as improper treatment can lead to cracks or other defects in the steel.

AR400 Steel Machining and Welding

AR400 steel can be machined and welded but requires some special considerations. Due to its high hardness, the steel is difficult to cut and shape and requires high-speed tools and cutting fluids. Welding AR400 steel also requires some expertise, as the steel is prone to cracking and warping if not soldered properly. Preheating the steel, using low-hydrogen electrodes, and controlling the welding temperature can all help prevent these issues.

![]()

![]()

![]()

![]()